Method for manufacturing a motor rotor assembly

A technology of a motor rotor and a manufacturing method, which is applied to electric components, electrical components, magnetic circuit rotating parts, etc., can solve the problems of low affinity, low surface tension of the coating, motor damage, etc. The effect of high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

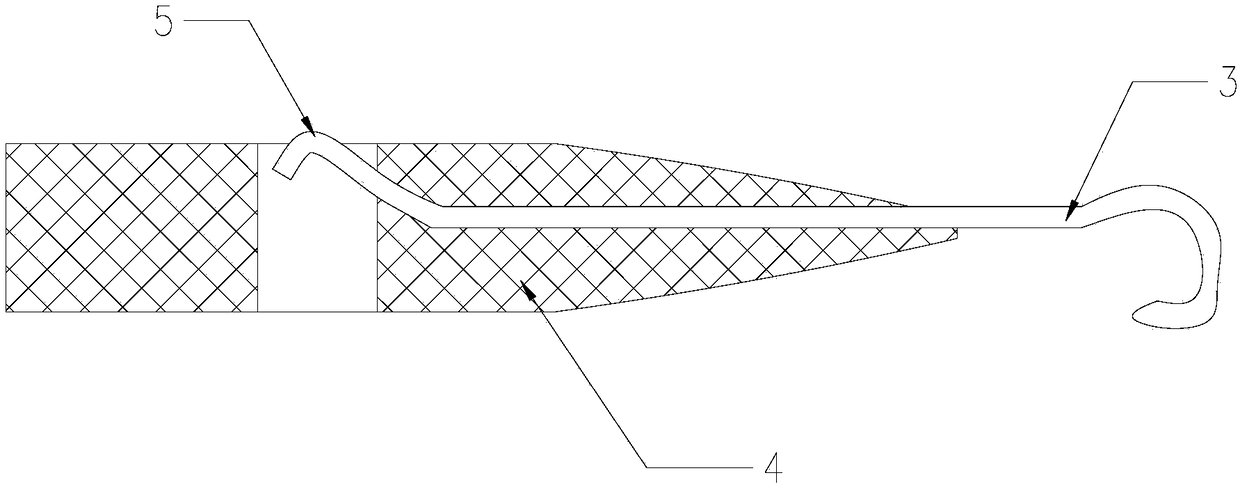

[0027] Embodiment one: if Figure 3-6 As shown, a method for manufacturing a motor rotor assembly includes the following steps:

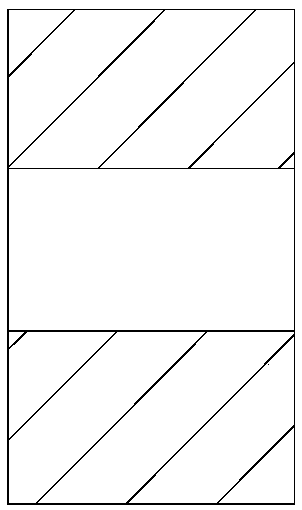

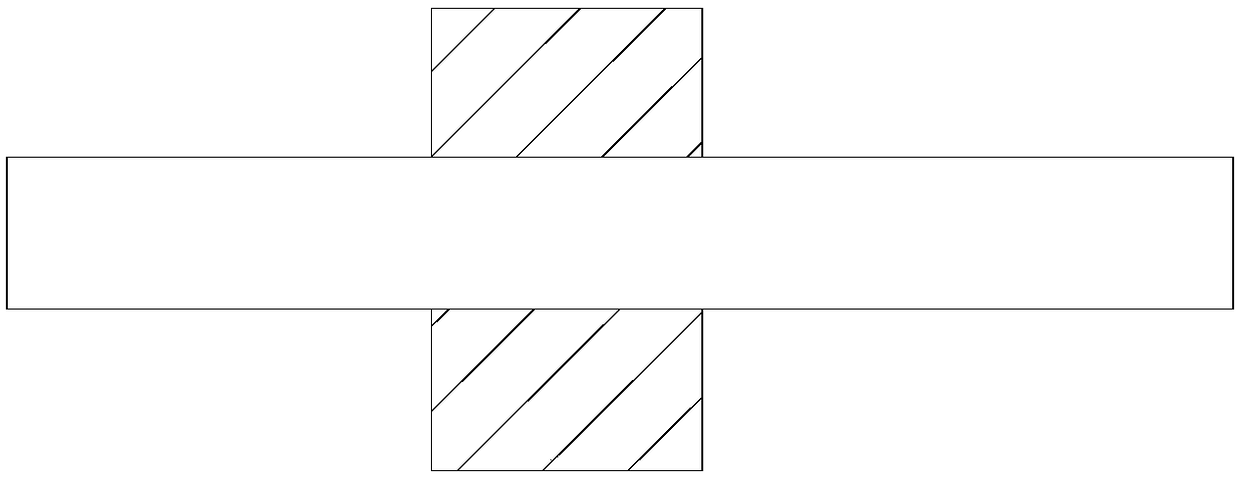

[0028] (1) Process the inner hole of the annular magnetic steel 1: the inner hole of the annular magnetic steel 1 is divided into a first inner hole 11 and a second inner hole 12, the diameter of the first inner hole 11 is denoted as D1, and the second inner hole The diameter of the hole 12 is marked as D2, the axial depth of the first inner hole 11 is marked as L1, the axial depth of the second inner hole 12 is marked as L2, the thickness of the ring magnetic steel 1 is marked as L, and the thickness of the cylindrical mandrel 2 is The outer diameter is recorded as D, D1 is 0.06mm larger than D, D2 is 0.2mm larger than D1, L=L1+L2, 1 / 3L≤L2≤1 / 2L;

[0029] (2) Electroplating is carried out to the annular magnet 1, and the electroplating layer is attached to the other surfaces of the annular magnet 1 except the inner surface after the electroplating;...

Embodiment 2

[0037] Embodiment two: if Figure 3-6 As shown, a method for manufacturing a motor rotor assembly includes the following steps:

[0038] (1) Process the inner hole of the annular magnetic steel 1: the inner hole of the annular magnetic steel 1 is divided into a first inner hole 11 and a second inner hole 12, the diameter of the first inner hole 11 is denoted as D1, and the second inner hole The diameter of the hole 12 is marked as D2, the axial depth of the first inner hole 11 is marked as L1, the axial depth of the second inner hole 12 is marked as L2, the thickness of the ring magnetic steel 1 is marked as L, and the thickness of the cylindrical mandrel 2 is The outer diameter is recorded as D, D1 is 0.06mm larger than D, D2 is 0.2mm larger than D1, L=L1+L2, 1 / 3L≤L2≤1 / 2L;

[0039] (2) Electroplating is carried out to the annular magnet 1, and the electroplating layer is attached to the other surfaces of the annular magnet 1 except the inner surface after the electroplating;...

Embodiment 3

[0048] Embodiment three: as Figure 3-6 As shown, a method for manufacturing a motor rotor assembly includes the following steps:

[0049] (1) Process the inner hole of the annular magnetic steel 1: the inner hole of the annular magnetic steel 1 is divided into a first inner hole 11 and a second inner hole 12, the diameter of the first inner hole 11 is denoted as D1, and the second inner hole The diameter of the hole 12 is marked as D2, the axial depth of the first inner hole 11 is marked as L1, the axial depth of the second inner hole 12 is marked as L2, the thickness of the ring magnetic steel 1 is marked as L, and the thickness of the cylindrical mandrel 2 is The outer diameter is recorded as D, D1 is 0.04mm larger than D, D2 is 0.1mm larger than D1, L=L1+L2, 1 / 3L≤L2≤1 / 2L;

[0050] (2) Electroplating is carried out to the annular magnet 1, and the electroplating layer is attached to the other surfaces of the annular magnet 1 except the inner surface after the electroplatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com