Combined piston ring with novel locating device and manufacturing method thereof

A technology of positioning device and piston ring, applied in the field of piston ring, can solve the problems of increased piston temperature, large damage of piston ring, low life of piston ring, etc., and achieve the effects of prolonging service life, preventing radial leakage and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

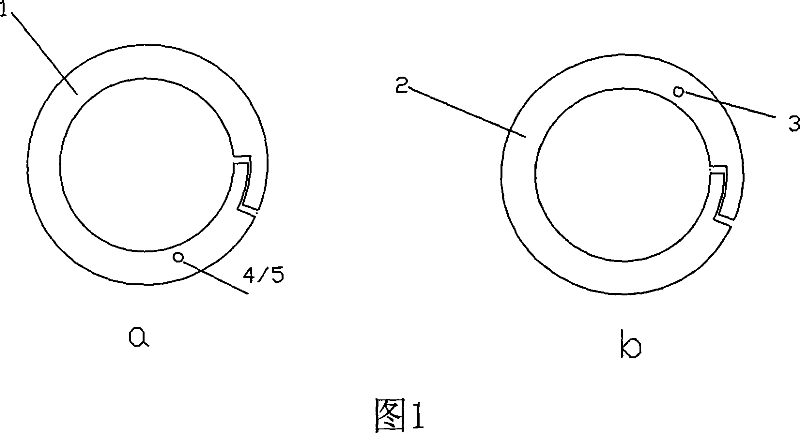

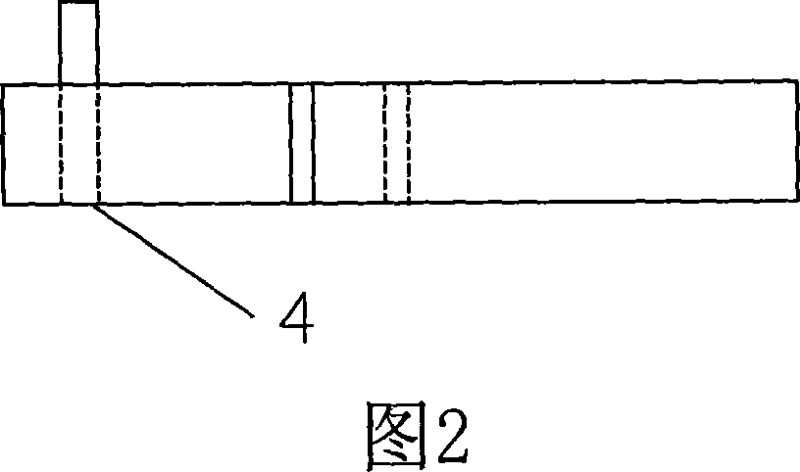

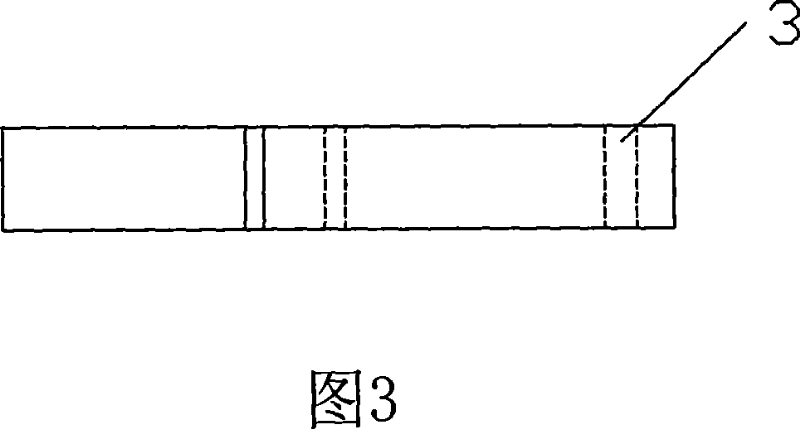

[0029] Fig. 1 is a structural schematic diagram of the first embodiment of the combined piston ring with the new positioning device according to the present invention; the two component rings are radial overlapping rings, as shown in the figure, a is the piston ring with the new positioning device of the present invention The upper component ring 1 of the combined piston ring is processed with a circular positioning pin connection hole 4 on the ring plane within the range of an angle of 90° with the port relative to the center of the piston ring. The optimal angle is less than or equal to 30°. The present embodiment is 30° to ensure that the positioning pin connecting hole 4 does not bear a large moment, and the diameter of the positioning pin connecting hole 4 is 0.9mm; b is the lower component ring 2 of the combined piston ring with a new positioning device in the present invention, A circular positioning groove 3 is processed on the ring plane within the range of 90° include...

Embodiment 2

[0031]Fig. 4 is a structural schematic diagram of the second embodiment of the combined piston ring with a new positioning device according to the present invention; Together they form a positioning cutout 6, which passes through the inner edge of the piston ring and is arc-shaped with a radial width of 1.4mm. A circular positioning pin connection hole 4 with a diameter of 0.9mm is processed on the ring forming an angle of 30° with the port relative to the center of the piston ring. The part where the positioning pin 5 is inserted into the positioning pin connection hole 4 is cylindrical, and the cross section of the positioning part It is arc-shaped and matches with the positioning notch 6. The arc length of the positioning notch 6 is greater than the arc length of the positioning pin 5. The positioning pin of this structure not only plays the role of positioning but also plays the role of sealing sealing piece; the positioning pin connecting hole 4 and the Corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com