Automatic steel backing plate broaching device and using method thereof

An automatic, steel-backed technology, applied in the field of auto parts, can solve the problem of low shear strength, and achieve the effect of obvious shear strength, obvious change, and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

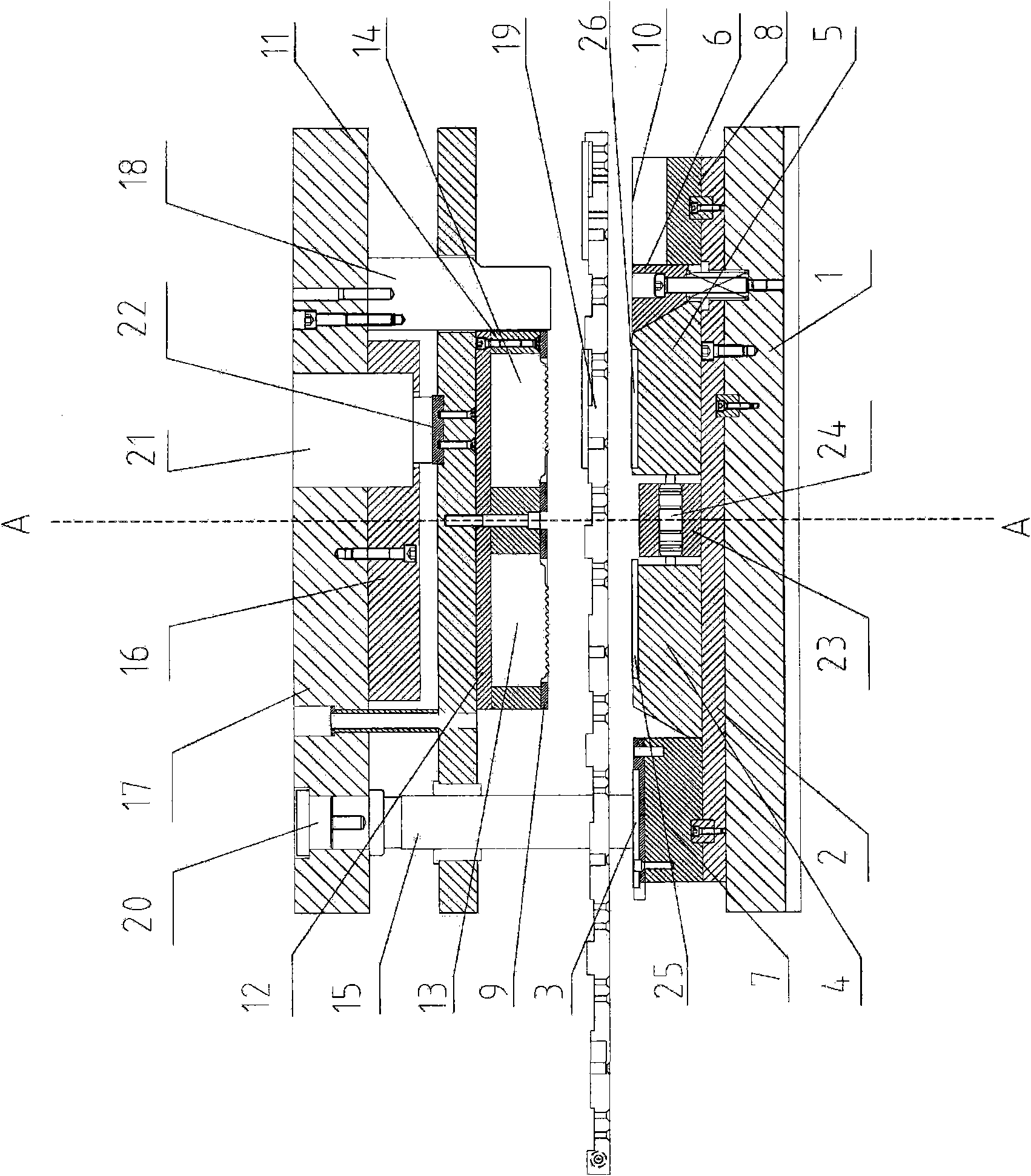

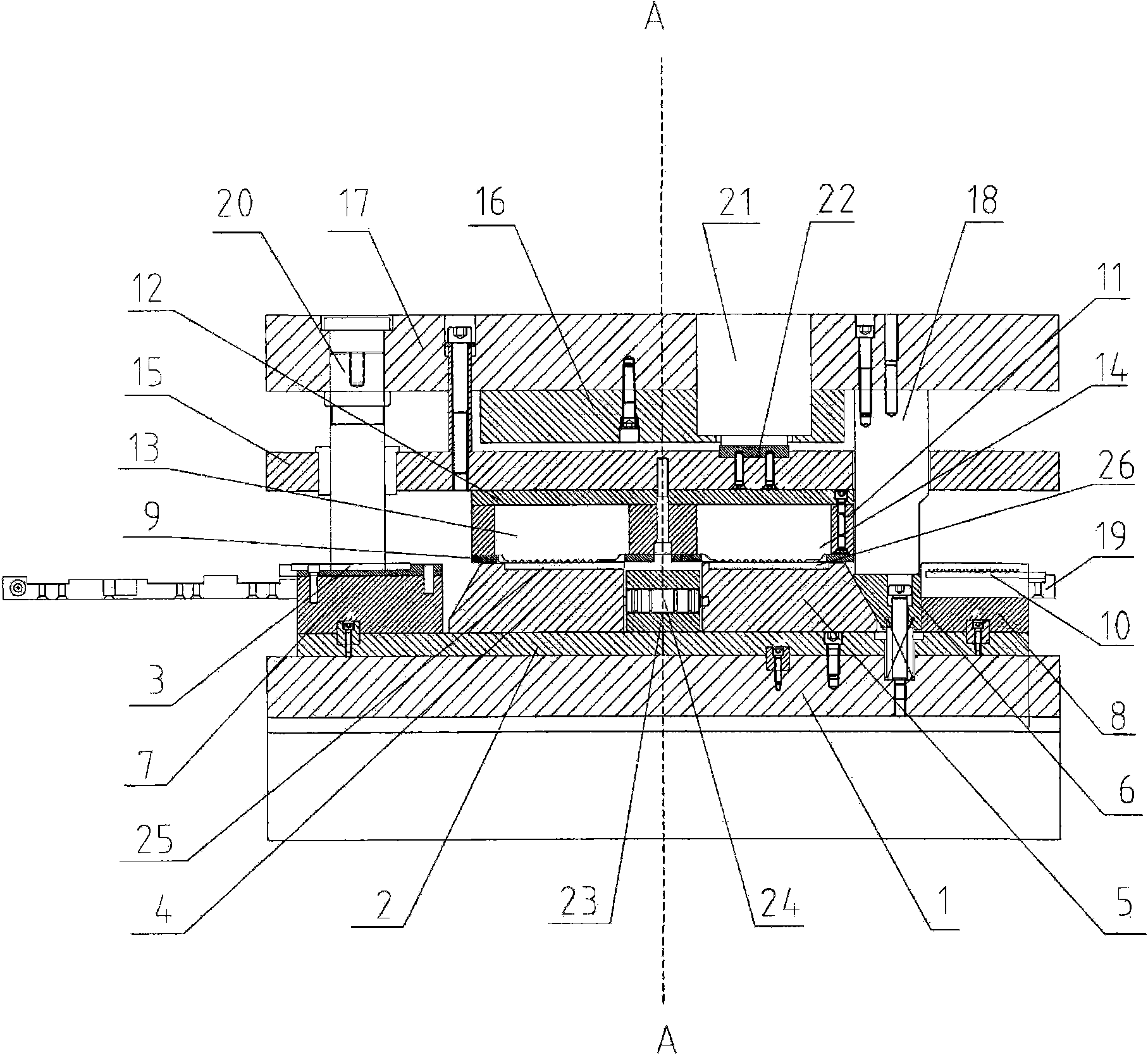

[0038] The automatic drawing device for steel back of the present invention and its use method will be described in further detail below in conjunction with the drawings.

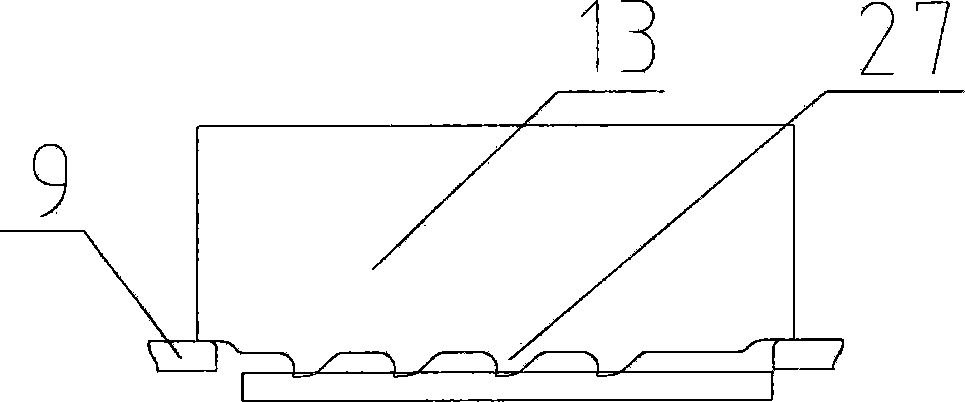

[0039] Such as figure 1 , figure 2 , image 3 As shown, the steel back automatic drawing device of the present invention includes an upper die base 17, which is connected to a hydraulic press, and is provided with a guide post 20 and a pressure spring 21; a movable support plate 15 is arranged parallel to the upper die base 17 and is spaced apart from the guide The column 20 and the pressure spring 21 are connected; the lower mold base 1, which is connected to the hydraulic press, is spaced in parallel with the movable pallet 15, and is located on both sides of the movable pallet 15 with the upper mold seat 17; the steel back automatic drawing device also includes a The forming device, the forming device includes: a blade fixing device, which is arranged under the movable pallet, including a blade spacer 12, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com