Processing technique for compressor shell

A processing technology and compressor technology, applied in the processing field of workpieces, can solve the problems of waste, increase production costs, hinder the development of enterprises and competition in the product market, etc., and achieve the effect of reducing production processes and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

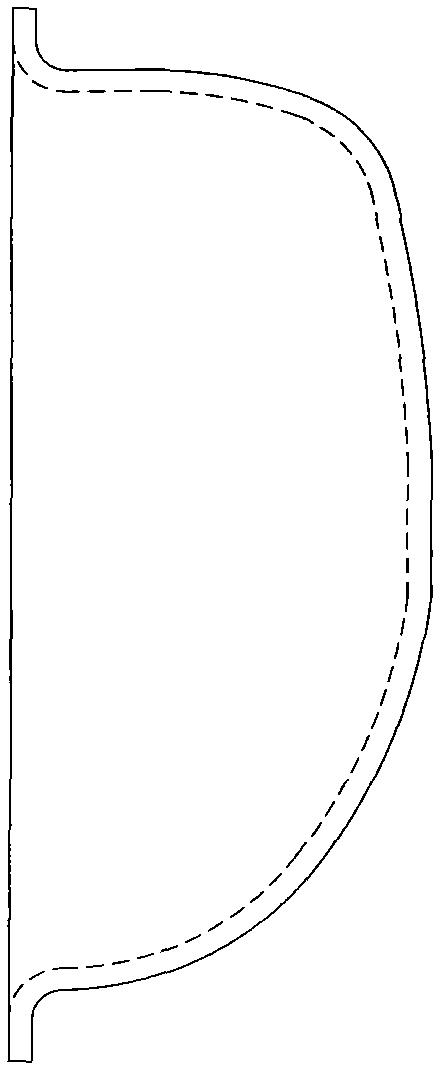

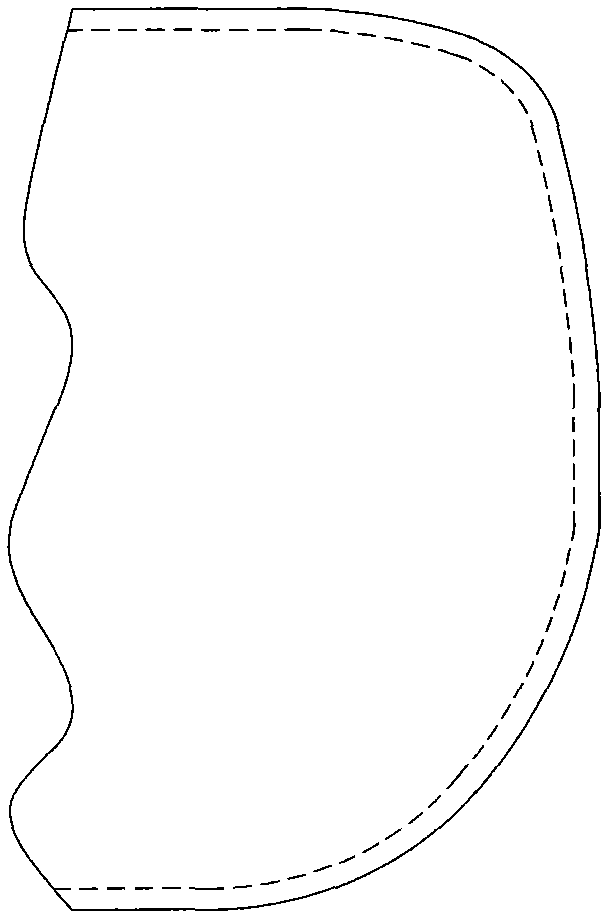

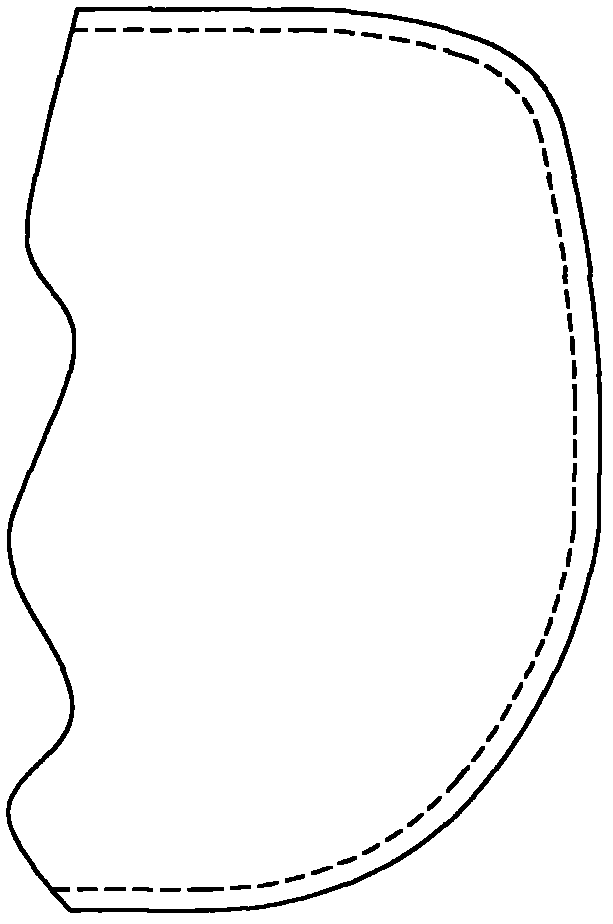

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples. The following examples are only used to illustrate the technical solutions of the present invention, but do not limit the present invention.

[0022] A processing technology for a compressor casing, the steps are as follows:

[0023] 1. Blanking: Blanking after determining the new blanking size of the compressor shell under the new process flow;

[0024] 2. Stretching: Stamp the blanked blank on the blanking die, punch out the stretched blank required for the stretch compressor shell, and confirm that the stretching depth is at least 3-4mm greater than the final depth of the part;

[0025] 3. Edge removal: Trim the edge of the stretched blank to get the part.

[0026] According to the depth of the rough blank after stretching and the size of the workpiece diameter, the final part can be obtained by removing the machining allowance by side cutting or turning the edge during edge remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com