Construction method of multi-storey section steel-stay cable three-dimensional support ultra-large span cast-in-situ cantilever beam

A construction method and technology of cantilever beams, applied in the direction of girders, joists, truss beams, etc., can solve the problems of deformation or inclination of concrete structures, difficulty in supporting formwork at high altitudes, and high construction difficulty, so as to achieve simple installation and dismantling, and reliable support structure , good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

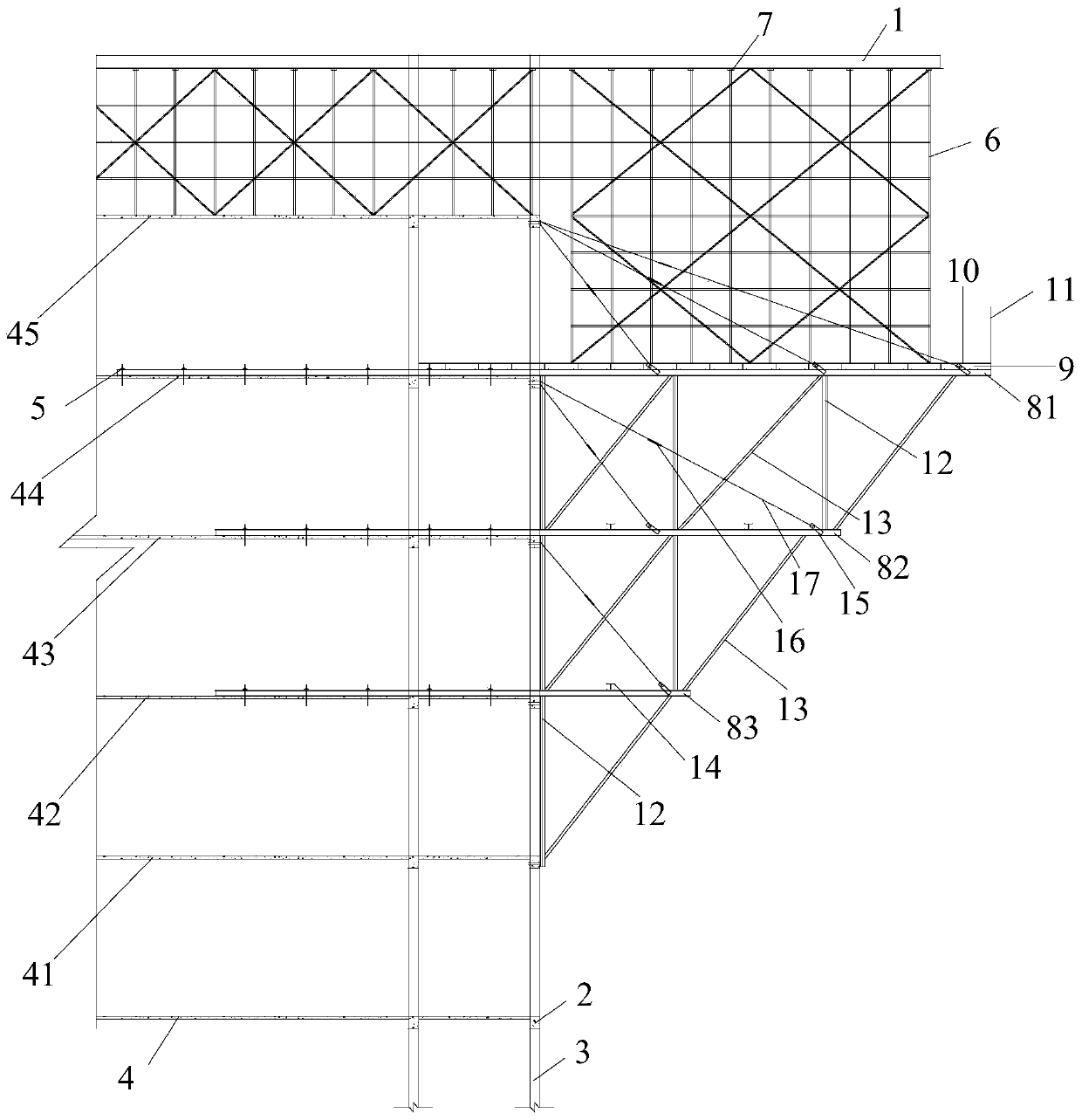

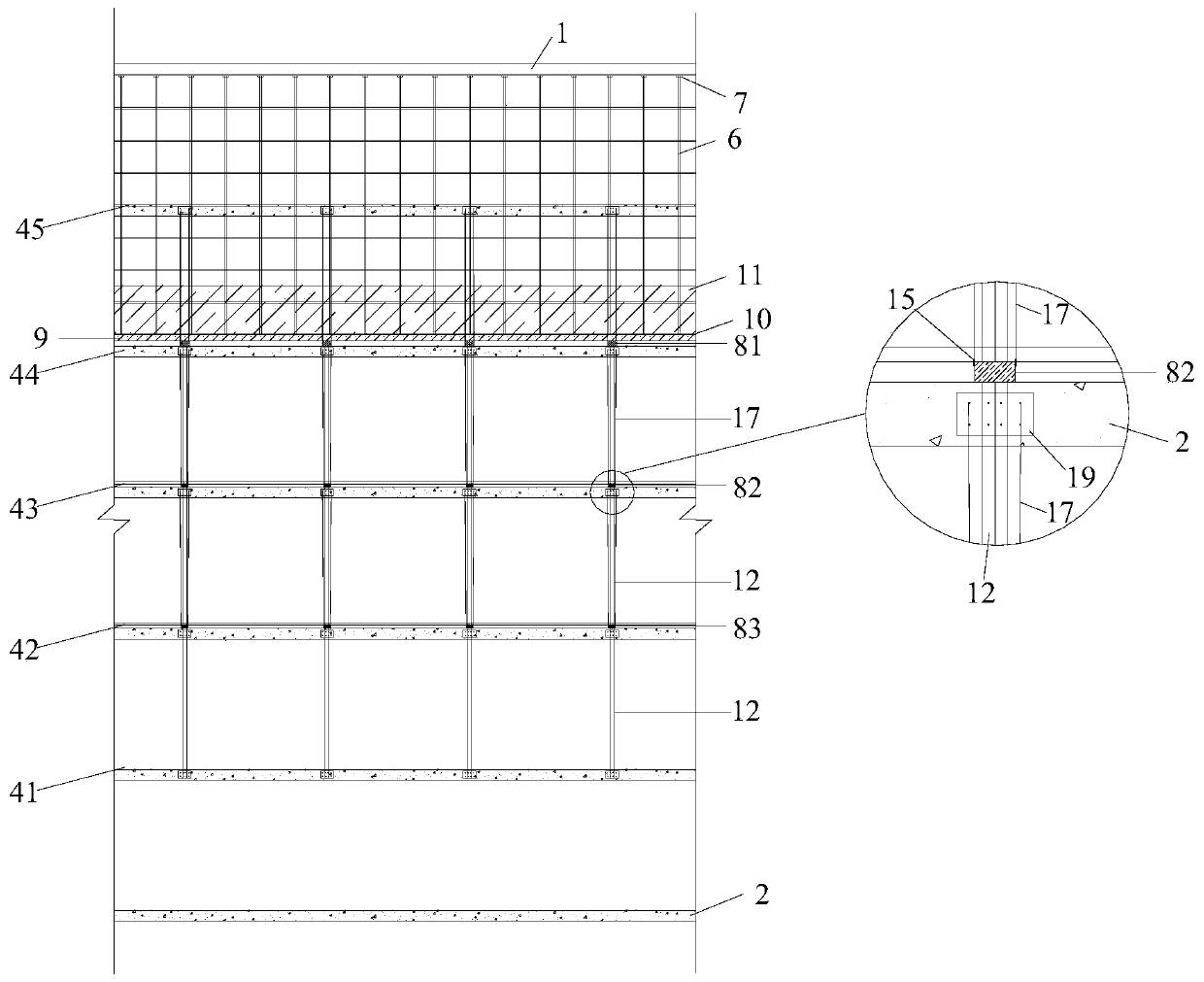

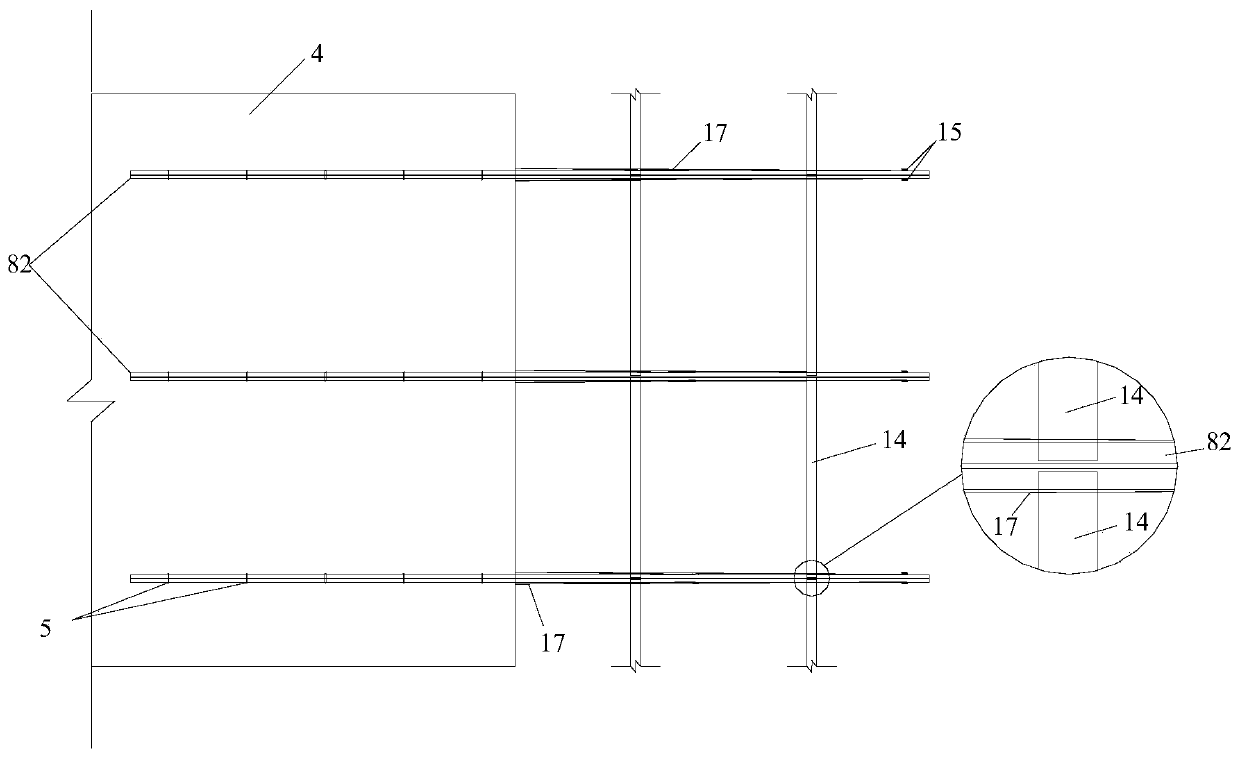

[0038] In order to deepen the understanding of the present invention, reference will be made to Figure 1 to Figure 8 , the embodiments of the present invention are described in detail, the following embodiments are implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0039] Figure 1~3 Among them, the long-span cantilever beam 1 has a cantilevered length of 10m, and three cantilevered steel bars 8 are used vertically as the construction platform support, and the horizontal spacing of the cantilevered steel bars 8 is 4m. N+4 floor 45 is only equipped with cable 17 but not cantilevered steel 8, the cantilevered steel 81 on the upper layer cantilevered with a length of 11m, the fixed length on N+3 layer 44 is 8m, and the cantilevered steel 82 in the middle layer has a cantilevered length of 7.5 m, arranged on the N+2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com