A high-speed centrifugal compressor

A high-speed centrifugal and compressor technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as reduced compression efficiency, single conduction path, and inability to cool down various functional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

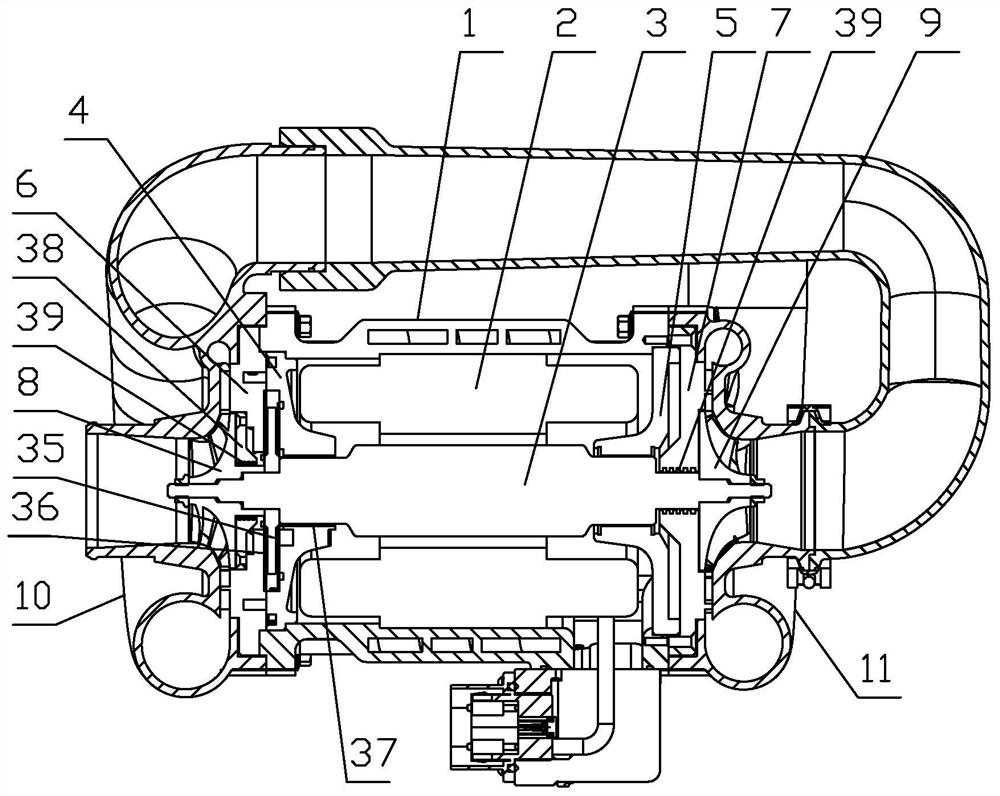

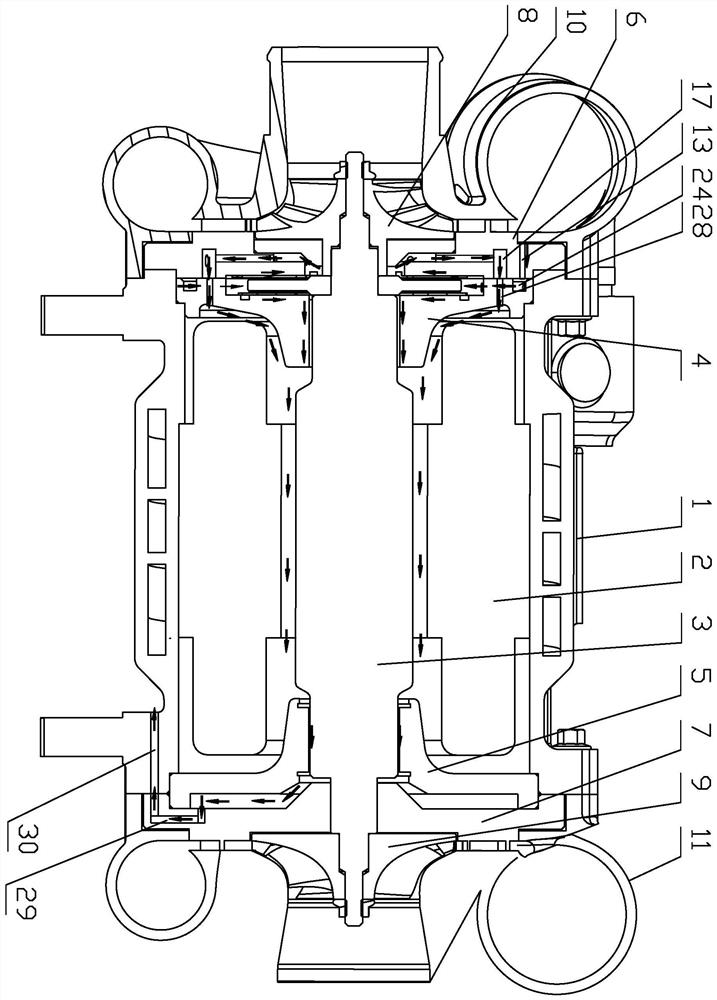

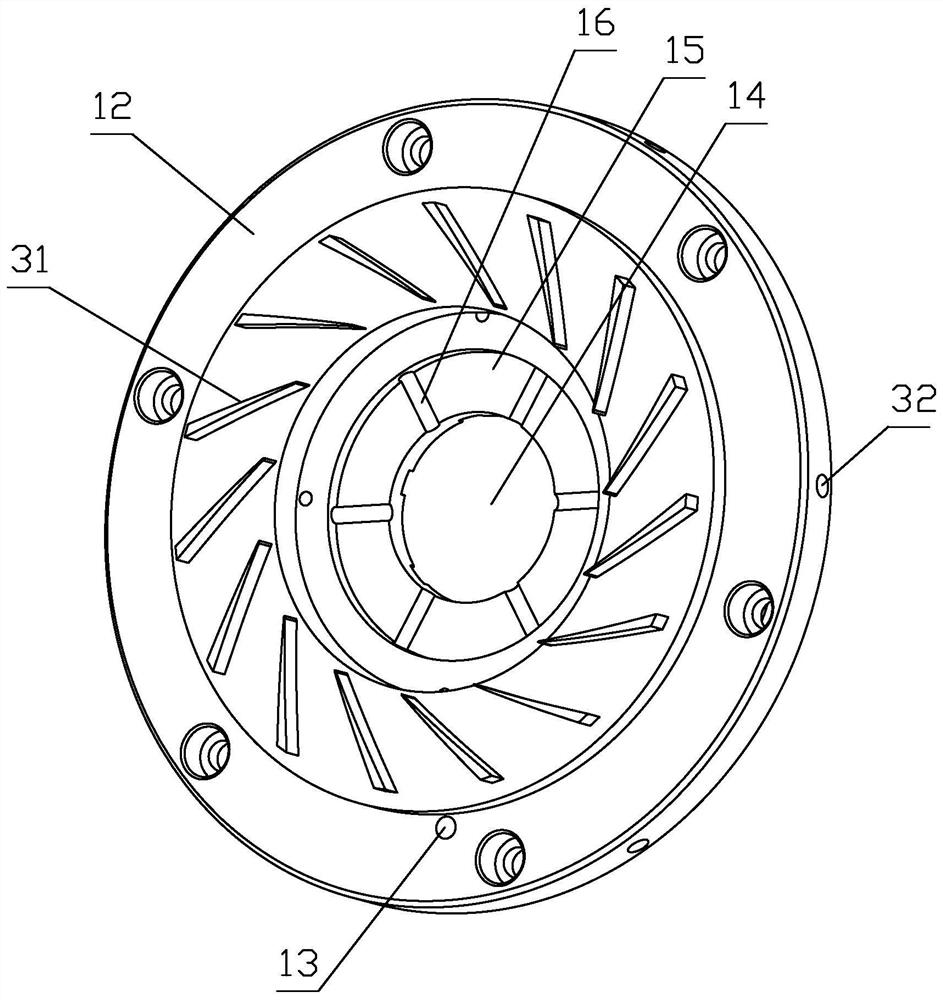

[0042] Such as Figure 1-12 As shown, a high-speed centrifugal compressor includes a housing 1, a stator 2, and a main shaft 3. The inner sides of both ends of the housing 1 are respectively installed with a primary bearing seat 4 and a secondary bearing housing 5 for supporting the main shaft 3. The housing 1 The first-stage diffuser 6 and the second-stage diffuser 7 are respectively installed on the outer sides of the two ends, and the first-stage diffuser 6 and the second-stage diffuser 7 pass through the two ends of the main shaft 3 to respectively install the first-stage worm gear 8 and the second-stage worm gear 9, A primary volute 10 and a secondary volute 11 are installed outside the primary worm wheel 8 and the secondary worm wheel 9, the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com