Broken seed cleaning method and equipment

A technology for cleaning equipment and seeds, applied in chemical instruments and methods, magnetic separation, solid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

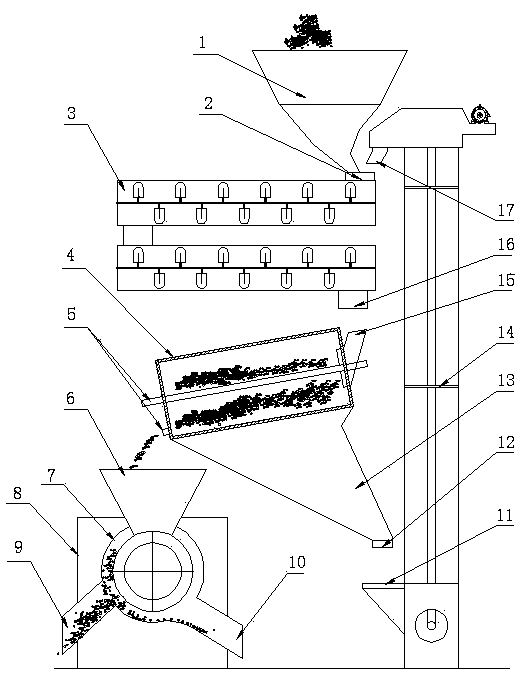

[0025] Embodiment 1: as figure 1 As shown, a kind of seed sorting and wound cleaning equipment includes a seed and metal powder mixing mechanism and an electromagnetic or permanent magnet sorting mechanism. The electromagnetic or permanent magnet sorting mechanism is an electromagnetic drum 7 with a frame 8 positioned above The feed port 6, the finished product seed outlet 9 and the damaged seed outlet 10 located below, the finished product seed outlet 9 and the damaged seed outlet 10 form a certain angle each other, and the finished product seed outlet 9 is located at the side where the seeds pass through first , the damaged seed outlet 10 is located on the side passing behind the seeds. A method for seed selection and damage cleaning, in which seeds and metal powder are fully mixed in the seed and metal powder mixing mechanism, so that the damaged seeds are adhered or infiltrated with metal powder, and then enter the electromagnetic drum 7, and the intact seeds are There i...

Embodiment 2

[0028] Embodiment 2: as figure 1 As shown, the seed and metal powder mixing mechanism is at least one agitator 3, the agitator 3 is an inclined flap type, there is a feed inlet 2 above the agitator 3, and the outlet 16 below the agitator is located Directly above the feed port 6 of the electromagnetic drum 7 . The inclined flap agitator 3 pushes the seeds forward until they fall into the feeding port 6 of the electromagnetic or permanent magnet drum while fully mixing the seeds with the metal powder. All the other are identical with embodiment 1.

[0029] In this embodiment, the mixing mechanism of seeds and metal powder is a stirrer 3, which has been greatly improved on the basis of embodiment 1. The inclined flap type stirrer 3 simulates human hands and completely replaces manual mixing of seeds and metal powder. , effectively reducing the workload and improving the mixing efficiency.

Embodiment 3

[0030] Embodiment 3: as figure 1 As shown, there is a metal powder recovery mechanism between the agitator 3 and the electromagnetic drum 7, the metal powder recovery mechanism is a cylindrical sieve 4, and the cylindrical sieve 4 is placed obliquely toward the electromagnetic drum 7, according to If required, the interior of the cylindrical sieve 4 is set as a multi-layer sieve, each layer of sieve has a discharge port 5, and the cylindrical sieve discharge port 5 is located in front of the electromagnetic or permanent magnet drum feed port 6. Above, there is a collection chamber 13 below the cylinder sieve 4 , and below the collection chamber 13 is a metal powder outlet 12 . All the other are identical with embodiment 2.

[0031] In this embodiment, the cylindrical sieve 4 screens out excess metal powder, and the metal powder screened out can be recycled and reused. While recovering excess metal powder, the problem of a large amount of metal powder adhering to the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com