Drum type seed dibble seeding and hole fertilizing seeder

A seeder and drum-type technology, which is applied to fertilizers and seeding equipment, can solve the problems of wasting seeds, increasing costs, and complex structures, and achieve the effects of improving fertilizer efficiency, solving structures, and improving fertilizer utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

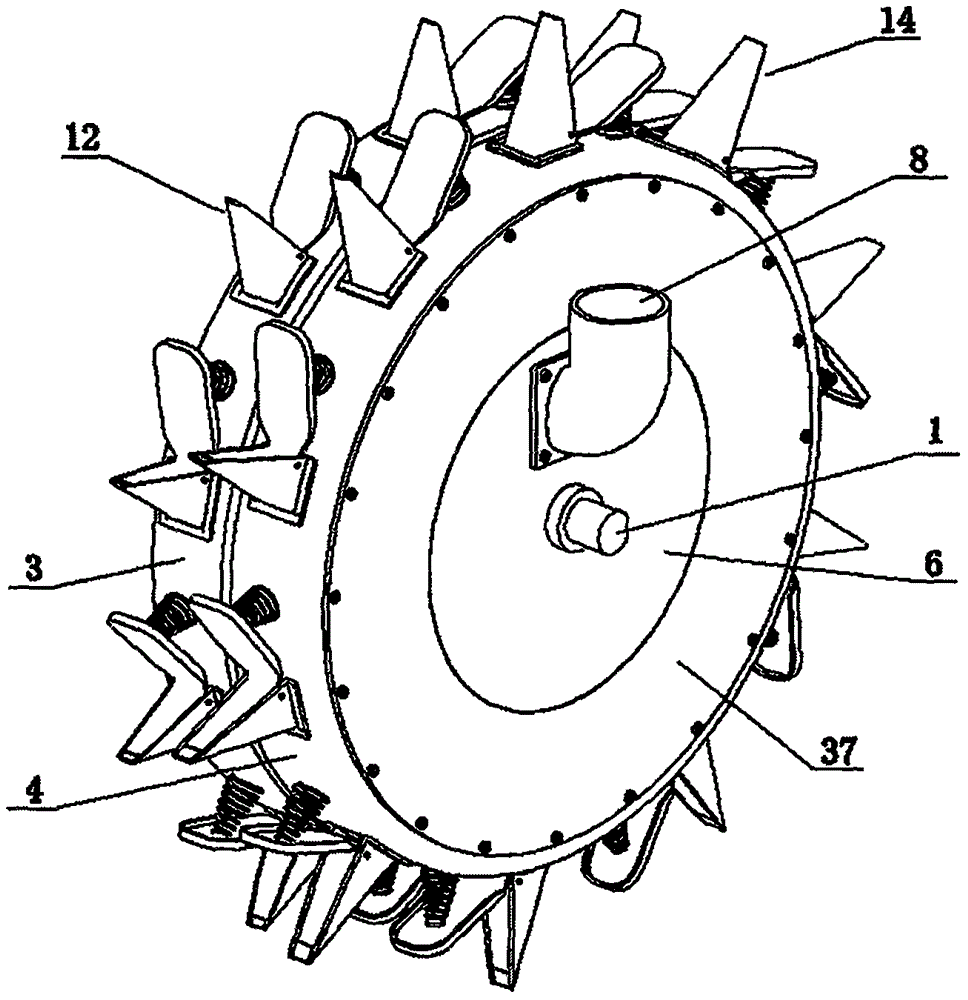

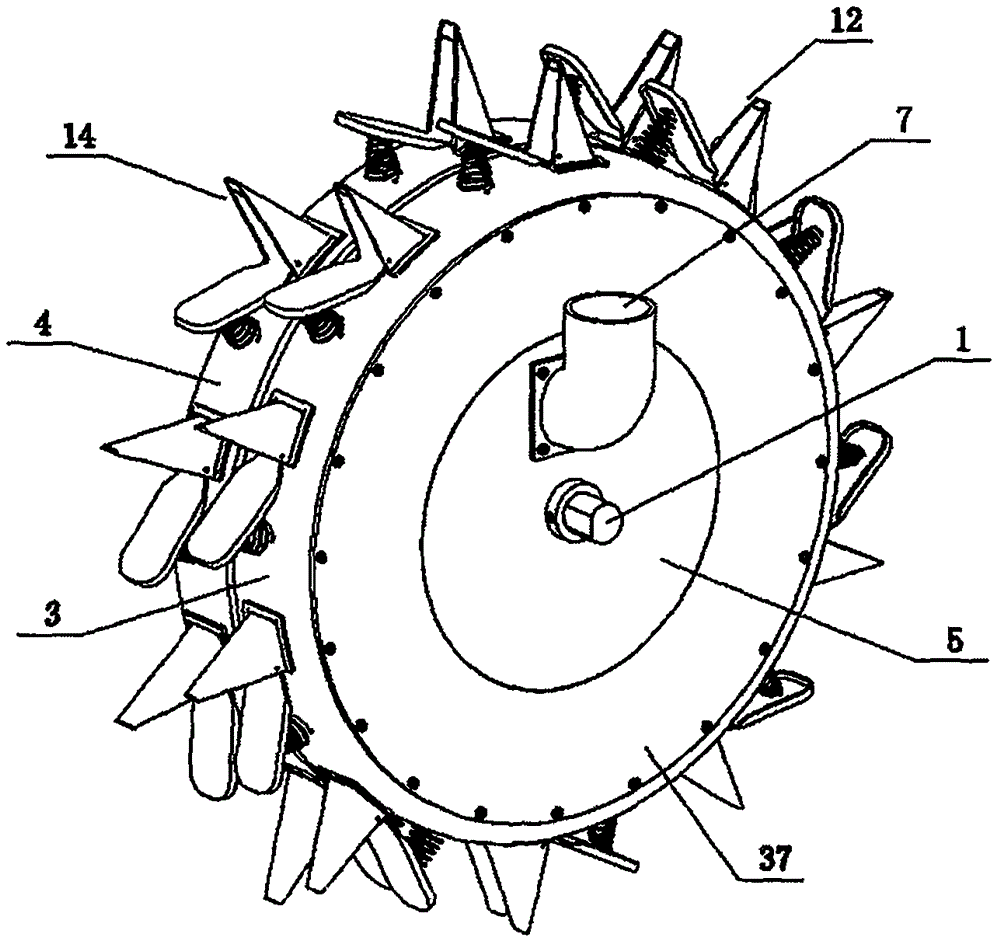

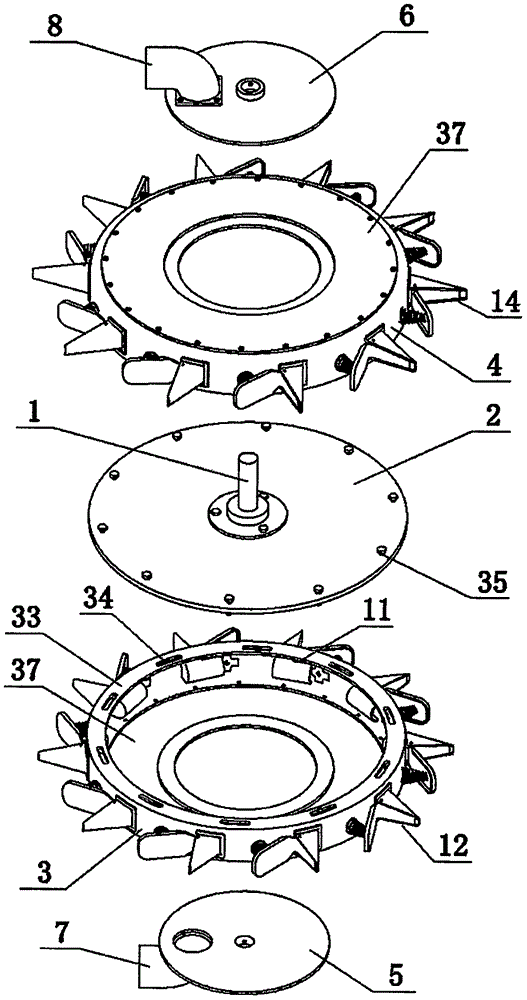

[0046] Embodiment 1: as attached Figure 1 to Figure 11 As shown, a drum-type on-demand seed hole fertilization seeder includes a main shaft 1 and a drum, and the drum includes a middle disk 2, and the two sides of the middle disk 2 are respectively a planting dynamic disk 3 and a fertilization dynamic disk 4, The center of the intermediate disc 2 is installed with the main shaft 1 through the bearing, and the sowing fixed disc 5 and the fertilization fixed disc 6 fixed on the main shaft 1 are arranged on the outer sides of the sowing movable disc 3 and the fertilizing movable disc 4, respectively, and the sowing fixed disc 5 and the fertilization fixed disc are fixed on the main shaft 1 The seed inlet 7 and the fertilizer inlet 8 are respectively arranged on the 6; ten seed discharge ports 9 and ten fertilizer discharge ports 10 with the same number are uniformly distributed on the surrounding walls of the sowing rotary disc 3 and the fertilization rotary disc 4, and the inner...

Embodiment 2

[0050] Embodiment 2: as attached Figure 12 to Figure 17 Shown, a kind of drum-type on-demand seed hole fertilization seeder, other structures are identical with embodiment 1, and difference is that it has adopted another kind of fertilizer discharger. Described fertilizer discharger comprises the small fertilizer box 38 that is fixedly installed on the main shaft, and the outside of small fertilizer box 38 is provided with fertilizer inlet 29, and the bottom of small fertilizer box 38 is provided with by fertilizer discharge shaft 40, fertilizer discharge sheave 41 and row. The fertilizer discharge mechanism that the fertilizer pinion 42 constitutes is fixed on the middle disk 2 with the large gear 43 that is meshed with the fertilizer discharge pinion 42 . A fertilization groove is arranged on each fertilizer outlet in the fertilization moving disk 4, and the fertilizer connection groove includes an arc-shaped groove body 44, and a fertilizer retaining plate 45 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com