Electronic reseeding and seeding device

A kind of seed metering device and electronic technology, applied in the direction of seeder parts, etc., can solve the problems of holes, high hole rate, uneven time distribution, etc.

Inactive Publication Date: 2013-08-28

曹天一

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The common feature of these two types of seed metering devices is that the seeds discharged from the seed metering device are sent into the soil inserter through the conduit. It takes a certain time for the seeds to pass through the conduit, and the seeds collide with the conduit wall in the conduit, resulting in the distribution of seeds per unit time. Inhomogeneous; in addition, the seed metering device adopts the drill method of sowing, which is easily affected by the texture and water content. When the soil viscosity is high or the water content is high, the soil inserter is easy to block the soil or block it, resulting in holes and lack of seedlings. The phenomenon of ridge breaking seriously affects the quality of sowing. During field operations, it is necessary to check the condition of the soil inserter at regular intervals, and solve problems in a timely manner.

There are two types of existing seed metering devices, mechanical and pneumatic. The mechanical type has outer grooved wheel type and socket type. It is simple in structure and low in cost. It is a form widely used in my country's production at present. Mutual extrusion, easy to damage seeds, not suitable for high-speed operation, high void rate, high reseeding rate, poor sowing consistency and uniformity, poor sowing quality; pneumatic seed metering devices include air suction type, air blowing type , Pneumatic type, pneumatic type has low seed damage rate and can adapt to high field operation speed, but requires constant air pressure, good air tightness, small mechanical vibration, high cost, no damage to seeds, and high leakage rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

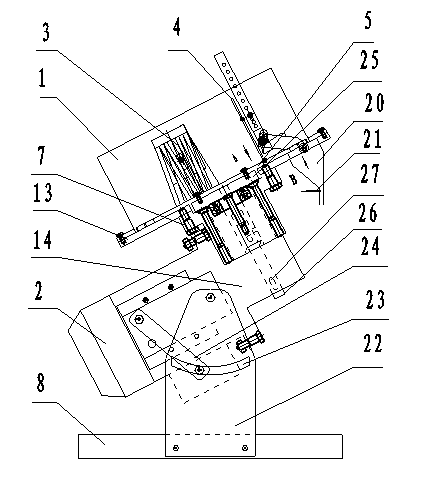

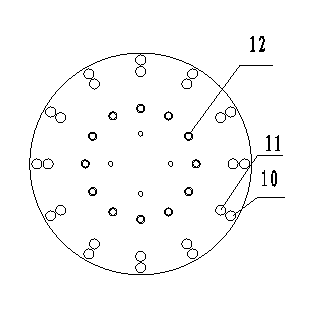

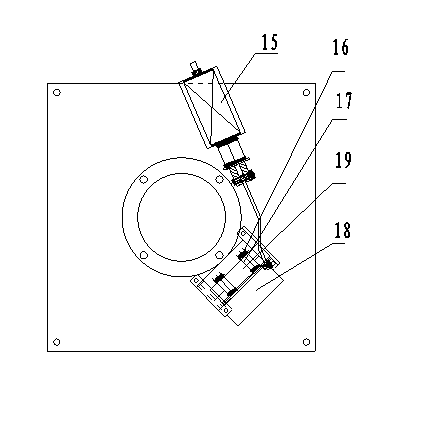

The invention provides an electronic reseeding and seeding device, which comprises a seed warehouse, a seed feeding mechanism and a reseeding mechanism, wherein the seed warehouse is positioned above a motor; the seed feeding mechanism, a seed cleaning brush and a position sensor are fixedly arranged on the inner circumferential surface of the seed warehouse; the position sensor is positioned above a seed filling disk; a moving trace of the position sensor is positioned on the radius of an induction sheet; a seed feeding wheel is positioned above the seed filling disk in the seed warehouse; a moving trace of the seed feeding wheel is positioned on the radius of a seed filling hole in the seed filling disk; a push-pull electromagnet, a seed baffle and a resetting spring form the reseeding mechanism; a transmission mechanism consists of the motor and a worm wheel and worm speed reducer; the motor is fixedly connected with a side vertical plate; the side vertical plate is fixed on a base; a cambered adjustment slot is arranged on the side vertical plate; one end of a connection plate is fixed on the motor, and the other end of the connection plate is fixed on the cambered adjustment slot; an angle of 35-40 degrees is formed between the motor and the horizontal panel of the base; when the motor rotates, the seed filling disk is driven to rotate; seeds in the seed warehouse enter the seed filling hole and a reseeding hole; and when the seed filling hole falls into a seed falling region, the seed feeding wheel feeds the seeds in the seed filling hole to a funnel.

Description

technical field [0001] The invention provides an electronic reseeding metering device, which belongs to the technical field of agricultural machinery. Background technique Commonly used seed metering devices in production are composed of two categories, one is mechanical type, including external groove wheel pull-type seed metering device with adjustable groove size, socket-type seed metering device with adjustable socket hole size, this type The characteristic of the mechanical seed meter is that the trapezoidal seed box is placed above the seed meter. The seed box needs to keep a certain amount of seeds. Due to the friction angle between the seeds, the seeds are pressed against each other in the seed box. The surrounding seeds cannot be turned to form a seed-filled vacuum area, and the seeds cannot enter the sockets and grooves, resulting in cavities; even if there are seeds entering the sockets and grooves, but because the states of the seeds entering the sockets and gr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01C7/20

Inventor 郭志东郭春瑶

Owner 曹天一

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com