Vacuum adsorption plug seedling precision seeder

A technology of vacuum adsorption and plug seedling cultivation, which is applied to the parts of planters and single-seed seeders, etc. It can solve the problems of low work efficiency, high rate of missed seeding, and plugging of seeding holes by seeds, and achieve high seeding efficiency and rate of missed seeding. Low, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

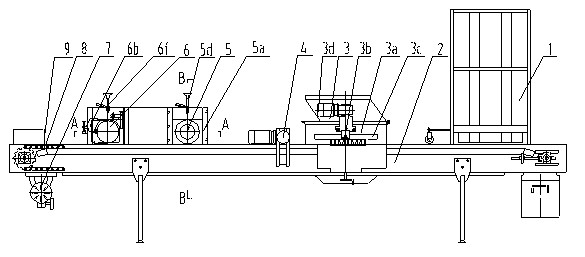

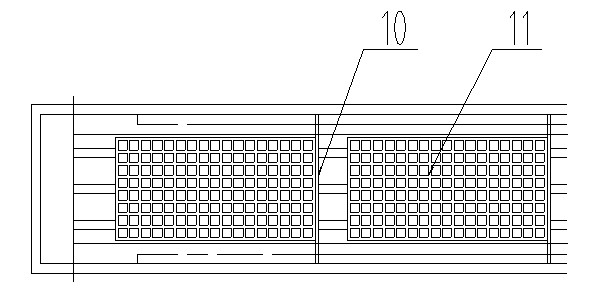

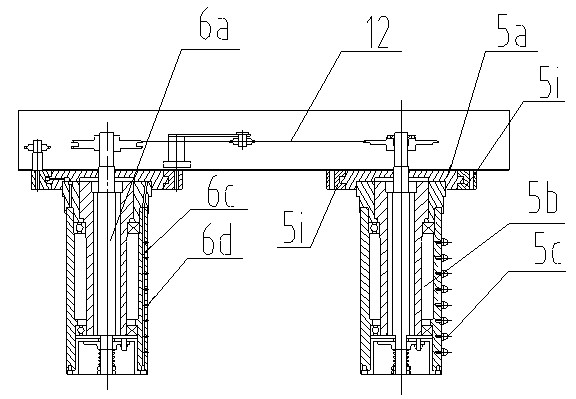

[0020] Such as figure 1 As shown, the vacuum adsorption type seedling seedling precision seeder of the present invention includes a conveying device 8 driven by a geared motor 7 installed on the frame 2, located above the conveying device and sequentially arranged and installed from the input end to the output end of the conveying device The tray feeding device 1, the covering soil flattening device 3, the leveling device 4, the pressure hole device 5, the vacuum adsorption seeding device 6, and the synchronous transmission device 12 is connected between the pressure hole device 5 and the vacuum adsorption seeding device 6, so as to The synchronous action of the pressure-cavitation device 5 and the vacuum adsorption seeding device 6 is maintained. Whenever the pressure-cavitation device presses out a group of cavities, the vacuum-adsorption sowing device can accurately sow seeds into the cavities. Transverse push rods 10 are evenly distributed on the conveying surface of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com