Preparation method of solid acid alkylation catalyst

An alkylation and catalyst technology, applied in the field of preparation of solid acid alkylation, can solve the problems of reducing the crystallinity and acidity of molecular sieves, destroying molecular sieve structure, reducing the surface area and pore volume of catalysts, and achieving high activity and stability, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] A method for preparing a solid acid catalyst, which is characterized in that it comprises the steps of kneading molecular sieves with acidic aluminum sol with a pH<5, a particle size of 20-300nm, and an alumina concentration of 5-20%, and extrusion molding.

[0013] The molecular screening is selected from one or more of X zeolite, Y zeolite and beta zeolite, wherein Y-type zeolite is preferred, and among said Y-type zeolites, the specific surface area is more preferably 500-700m 2 Modified Y zeolite with a pore volume greater than 0.35mL / g and a unit cell size of 2.450-2.465nm.

[0014] The aluminum sol is nano aluminum sol, the sol is acidic aluminum sol (pH<5), the particle size in the sol is 20-300nm, and the concentration of aluminum oxide is 5-20%.

[0015] The preparation method may also include adding water to ensure a certain water-to-powder ratio of the mixed powder, such as 0.8, and kneading evenly before extruding, drying and roasting the obtained wet strips...

Embodiment 1-3

[0024] This example illustrates the alkylation catalyst of the present invention and its preparation process.

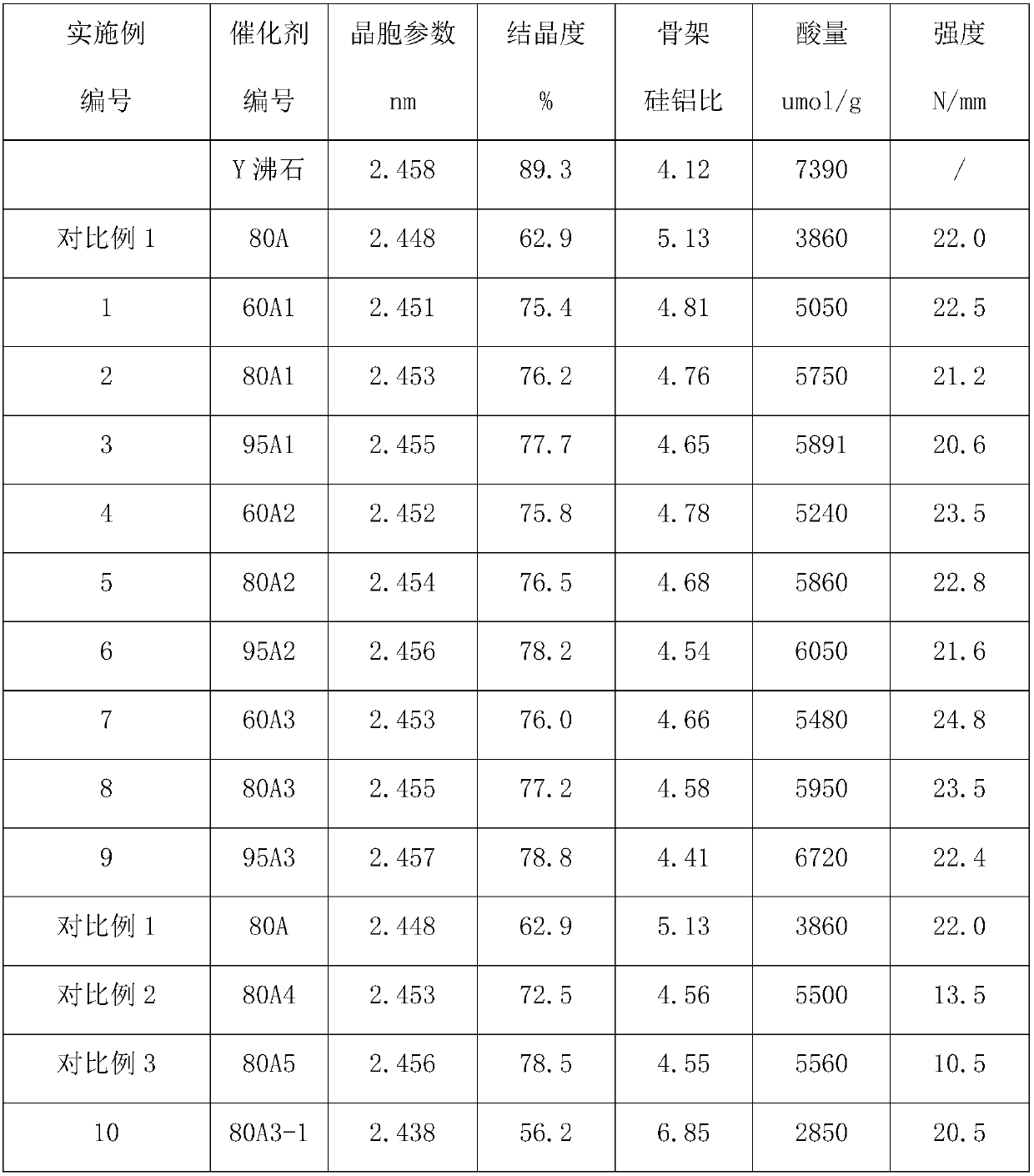

[0025] Y zeolite (specific surface area 680m 2 / g, pore volume 0.36mL / g, unit cell 2.46nm, Sinopec Catalyst Branch) and aluminum sol Al1 (aluminum oxide concentration is 5%, average particle size 20nm, pH is 4.2, Sinopec Catalyst Branch) by weight Mix the ratio of 60:40, 80:20 and 95:5 on a dry basis, and add water to ensure that the water-powder ratio of the mixed powder is 0.8, knead evenly and then extrude the strips, and the obtained wet strips are dried and calcined to obtain a molded catalyst The finished products are named 60A1, 80A1 and 95A1 respectively, and the properties of the obtained catalysts are shown in Table 1.

[0026] Table 1 lists the relevant test data of Y zeolite at the same time.

Embodiment 4-6

[0028] This example illustrates the alkylation catalyst of the present invention and its preparation process.

[0029] Y zeolite and Al2 (aluminum oxide concentration is 15%, average particle size 150nm, pH is 3.8, Sinopec Catalyst Branch Company) is mixed in the ratio of 60:40, 80:20 and 95:5 by weight dry basis percentage respectively, and pass Add water to ensure that the water-powder ratio of the mixed powder is 0.8, knead evenly and then extrude the strips. The obtained wet strips are dried and calcined to obtain finished catalyst products, which are respectively named 60A2, 80A2 and 95A2. The properties of the obtained catalysts are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| unit cell dimension | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com