sand screening machine for construction machinery

A technology of construction machinery and sand screening machine, which is applied in the fields of screening, solid separation, chemical instruments and methods, etc., can solve the problems of reducing the area of sand and gravel in the screening drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

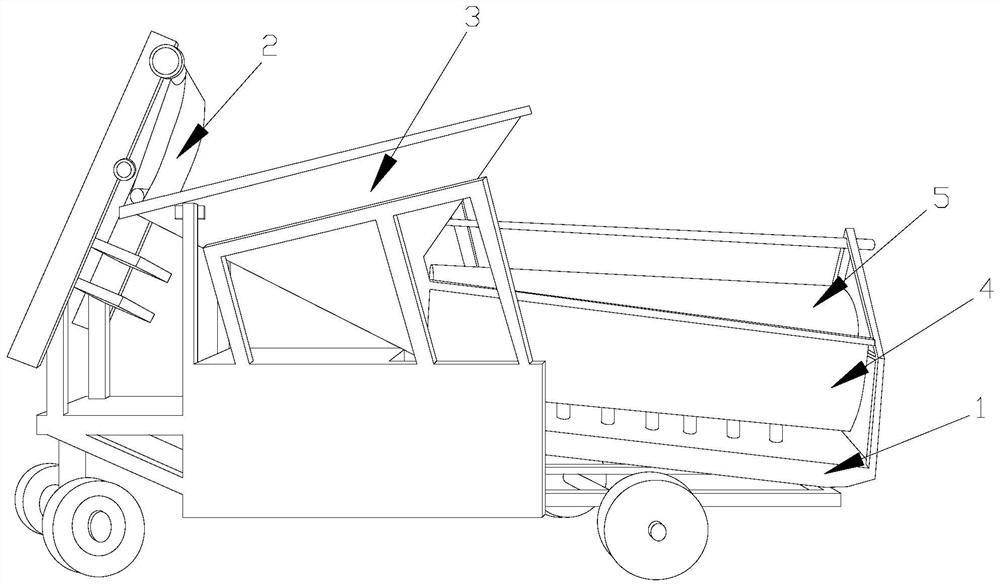

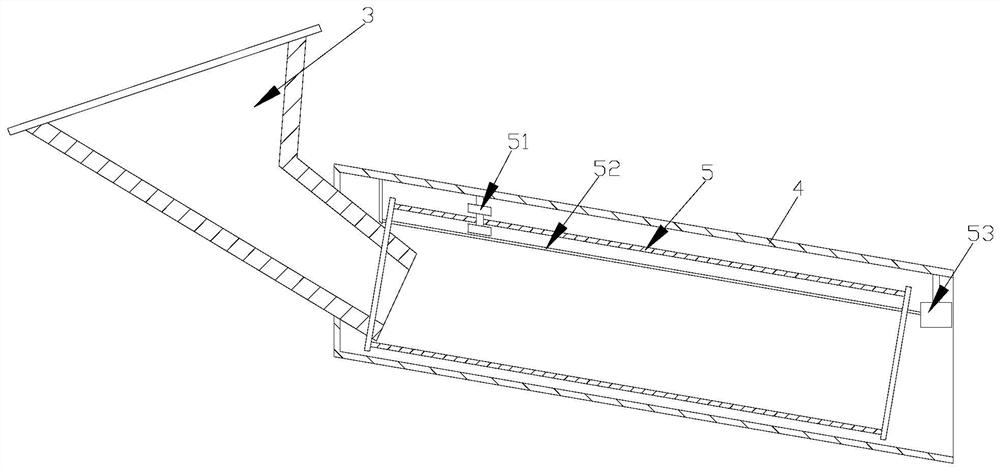

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiment of the present invention is as follows: its structure comprises base 1, conveyor belt 2, sand feeding bucket 3, sand loading bucket 4, sand screening bucket 5, conveyor belt 2 is installed on the left side of the top of described base 1, and described sand feeding bucket 3 is arranged below the conveyor belt 2, the sand loading bucket 4 is embedded on the right side of the sand feeding bucket 3, the sand screening bucket 5 is nested inside the sand loading bucket 4, and the sand screening bucket 5 includes A mud device 51, a mud guide block 52, and a mud collection tank 53, the mud removal device 51 is embedded and fixed on the top of the sand screen bucket 5, the mud guide block 52 runs through the sand screen bucket 5, and the mud collection tank 53 It is arranged at the end of the mud guide block 52.

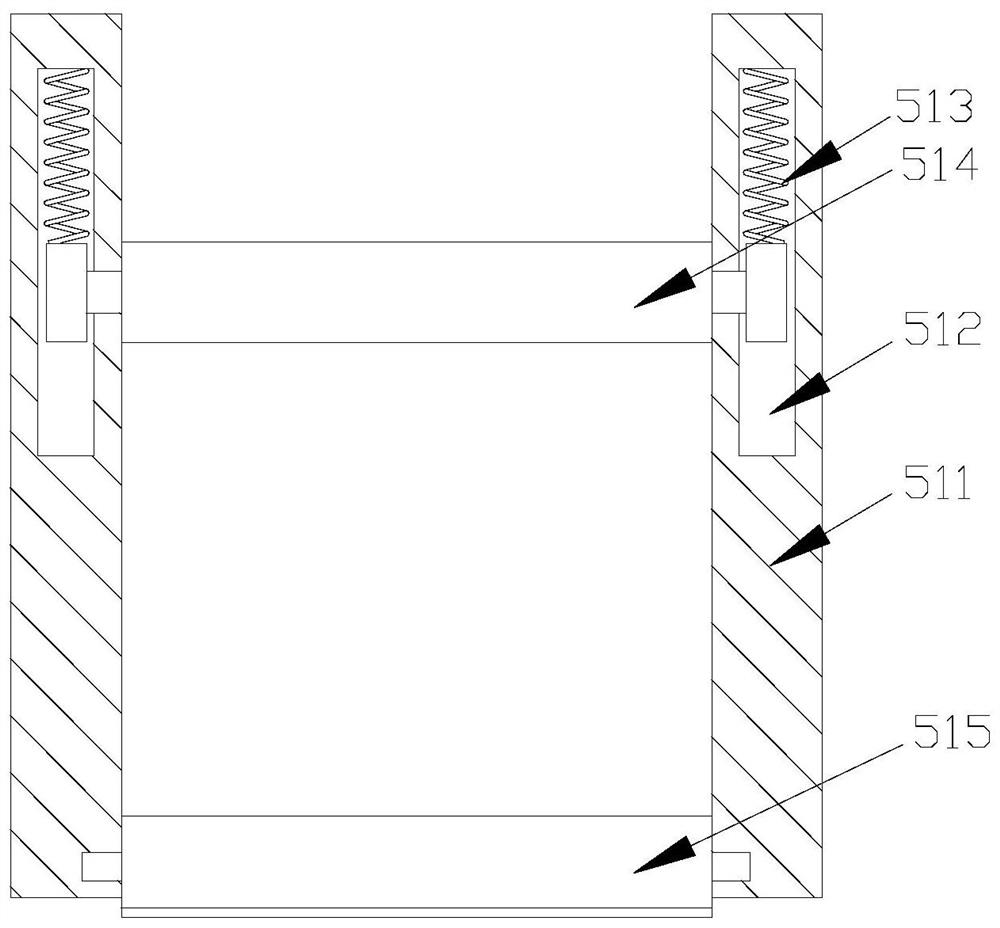

[0027] The desilting device 51 is composed of a support column 511, a slide groove 512, a firs...

Embodiment 2

[0031] Example 2: Please refer to Figure 6-Figure 8 The specific embodiments of the present invention are as follows: the top mud block a22 includes a rotating ball b1, an engaging groove b2, a third spring b3, a clamp b4, and a puncture head b5, and the rotating ball b1 is embedded in the top mud block a22. At the lower end, the engaging groove b2 is set on the inner side of the top mud block a22, the third spring b3 is installed on the inner side of the engaging groove b2, and the middle of the bottom of the clamping plate b4 is fixed on the top of the third spring b3 , the puncture head b5 is arranged on the top of the top mud block a22, the puncture head b5 is connected with the clamping plate b4, and the puncture head b5 is conical, which is beneficial for the puncture head b5 to pass through the sand sieve bucket 5.

[0032] The puncture head b5 includes a gear groove b51, a gear b52, a bayonet rod b53, and a retractable device b54. There are two gear grooves b51, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com