Capacitance induction system

A capacitive sensing and equivalent capacitance technology, applied in electrical components, electronic switches, electrical digital data processing, etc., can solve the problems of different shapes, sizes, unevenness, and different potentials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A circuit block diagram of a preferred embodiment of the capacitance sensing device of the present invention as shown in Figure 4, the capacitance sensing device 4 of this embodiment is a capacitive touch panel, including an insulating substrate 41 and several capacitance sensing components 42 .

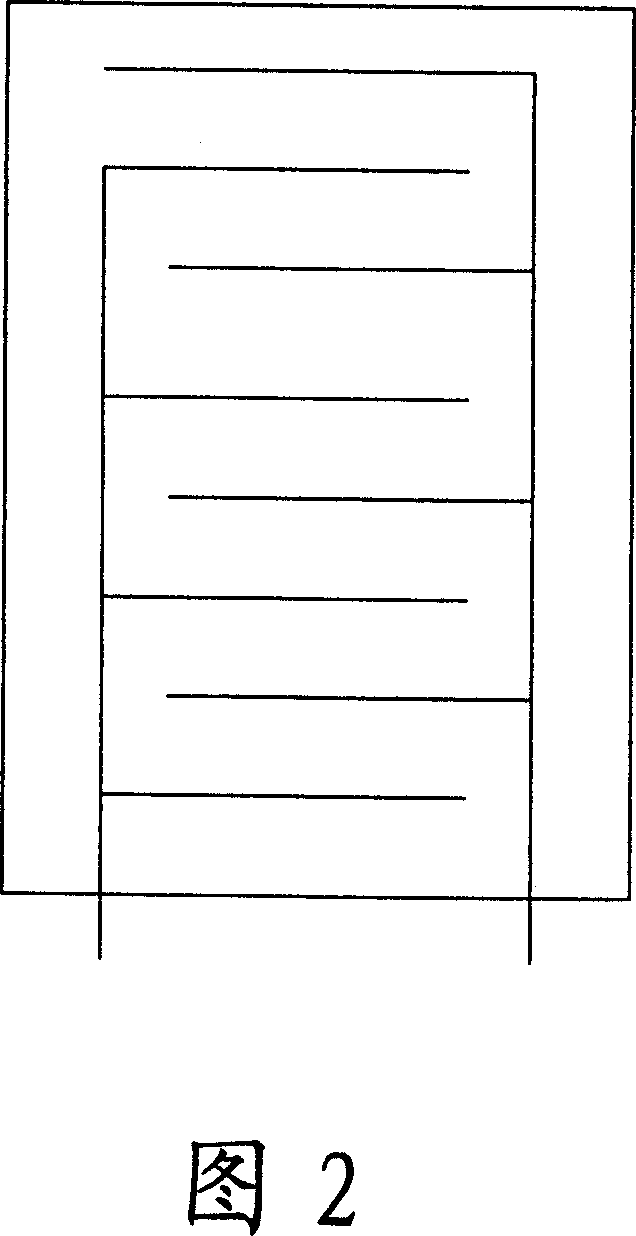

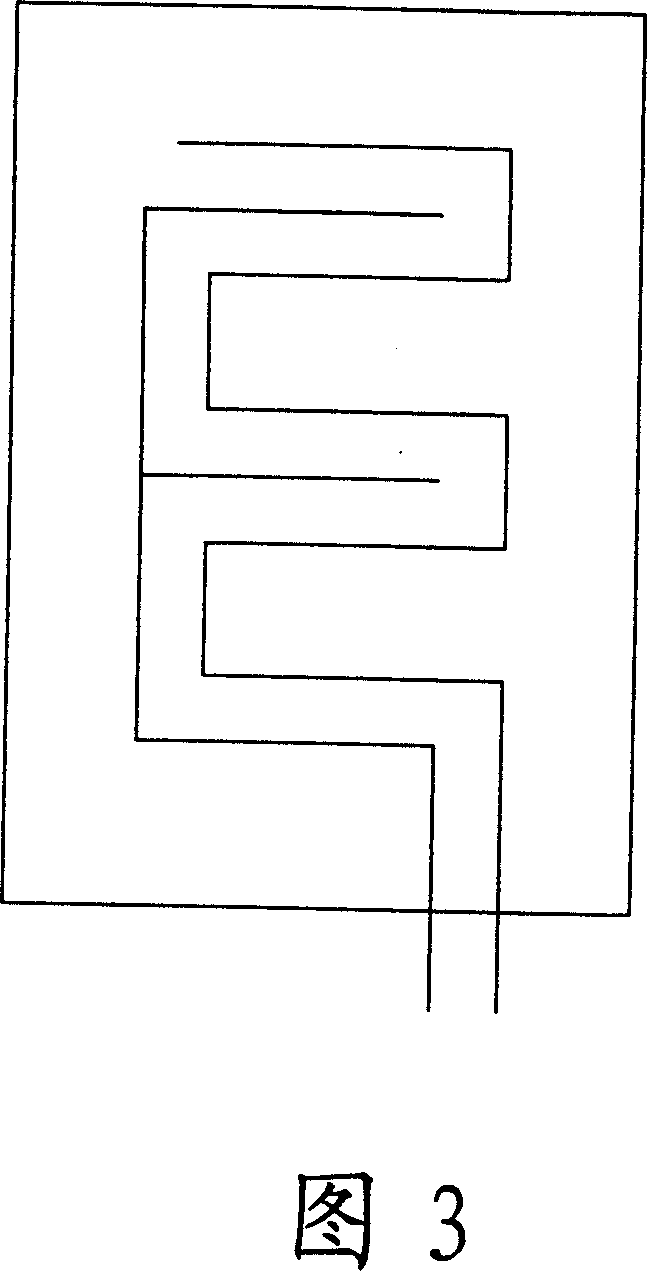

[0019] The insulating substrate 41 is a circuit substrate such as an FR4 board or a flexible board (Membrane), and the capacitive sensing components 42 are used as a touch button, which are formed on the insulating substrate 41 in a matrix arrangement. As shown in FIG. 5 , the structure enlarged view of each capacitive sensing element 42 includes a first electrode 43 and a second electrode 44 .

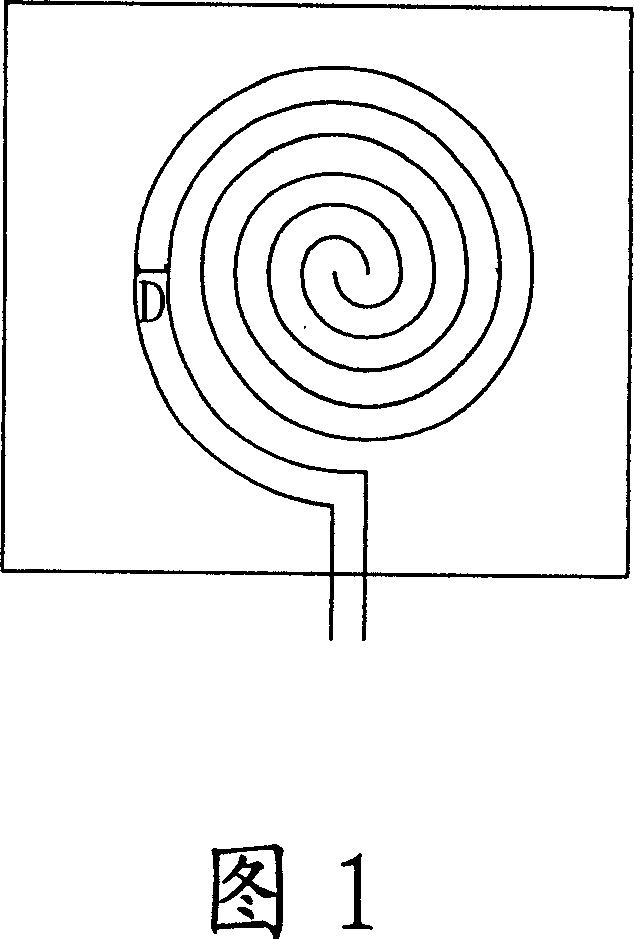

[0020] The first electrode 43 is a circular structure in the present embodiment, has an area (A), and the second electrode 44 is an equidistant distance from the first electrode 43 (distance (D)) around the first electrode 43. The ring on the periphery of the electrode 43 can form an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com