Airtight type drainage tube inner wall cleaning device

A technology for cleaning devices and drainage tubes, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of blockage of drainage tubes, greatly increased medical expenses, and limited improvement of overall effects, and achieves extended use. The effect of time, saving medical expenses and avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

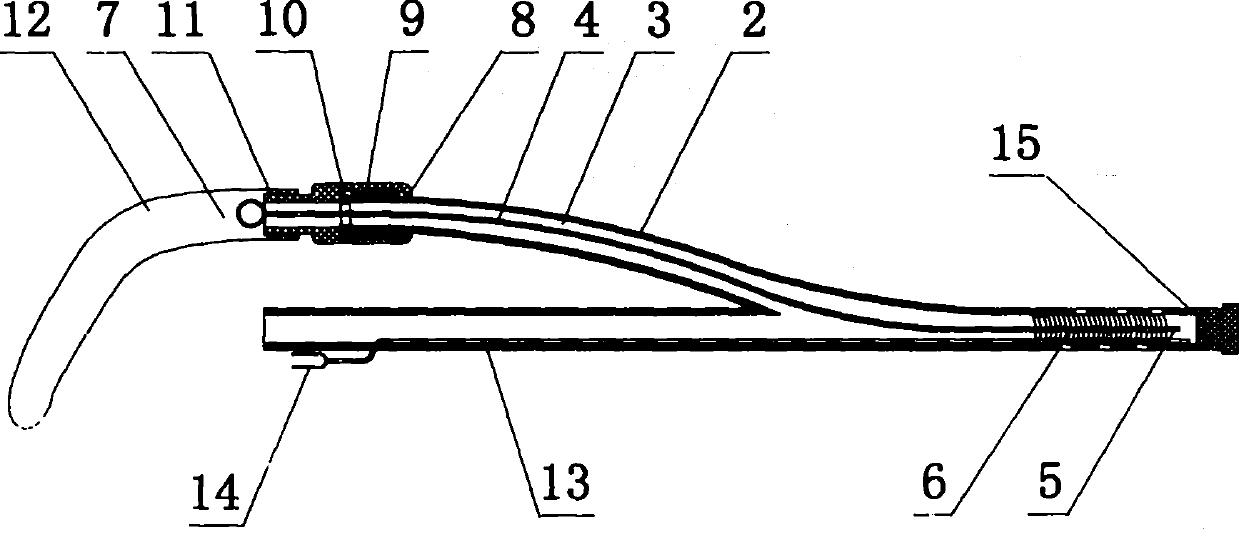

[0014] As shown in Figure 1, the drainage tube 1 of the present invention is a soft plastic tube with a plurality of side holes in the front section. The cleaning channel tube 2 with the same diameter, the angle between the cleaning channel tube 2 and the drainage tube 1 is 10-20°, the cleaning channel tube 2 is equipped with a cleaning brush 3, and the brush rod 4 of the cleaning brush 3 is made of elastic material Its length is slightly longer than the length of the pipeline from the tail end of the cleaning channel tube 2 to the head end of the drainage tube 1. The head end of the brush bar 4 is a needle 5, and the rear of the needle 5 is a cleaning brush head 6, and the outer contour diameter of the cleaning brush head 6 is slightly larger than the inner diameter of the drainage tube 1. The tail end of the brush bar 4 has a brush handle 7. The tail end of the cleaning channel pipe 2 is provided with a pipe joint 8, one end of which has an internal threaded port 9, and the...

example 2

[0017] Concrete operation process of the present invention:

[0018] Before use, check whether the brush rod 4 can slide and rotate freely in the center hole of the pipe joint 8, and check whether the tail end of the cleaning channel pipe 2 and the internal thread 9 and the "O"-shaped sealing ring 10 are in an airtight state. Sleeve the open end of the brush bar operating space sealing sleeve 12 on the anti-retraction interface seat 11 of the pipe joint 8 and tighten it. Pull the brush handle 7 to pull the brush rod 4 together with the cleaning brush head 6 into the lumen of the cleaning channel tube 2. At this time, the lumen of the drainage tube 1 remains unobstructed. A safety plug 15 is inserted into the opening of the front end of the drainage tube 1 to prevent the puncturing needle 5 from stretching too far forward and piercing the outer dressing when cleaning. During use, if the lumen of the main drainage tube 1 of the side hole section is found to be clogged, hold the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com