Foaming polyvinyl formal microbial carrier and preparation method thereof

A polyvinyl formal, microbial carrier technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Microorganisms, small specific surface area of carriers, etc., to achieve the effect of promoting nitrification and denitrification, improving treatment efficiency, and simple production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

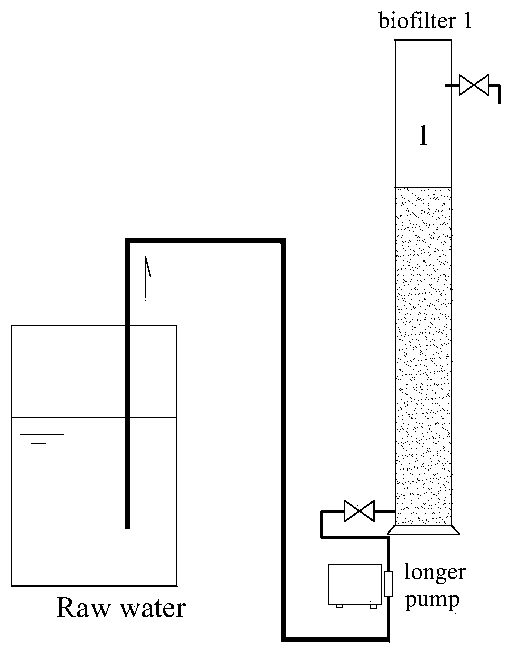

Method used

Image

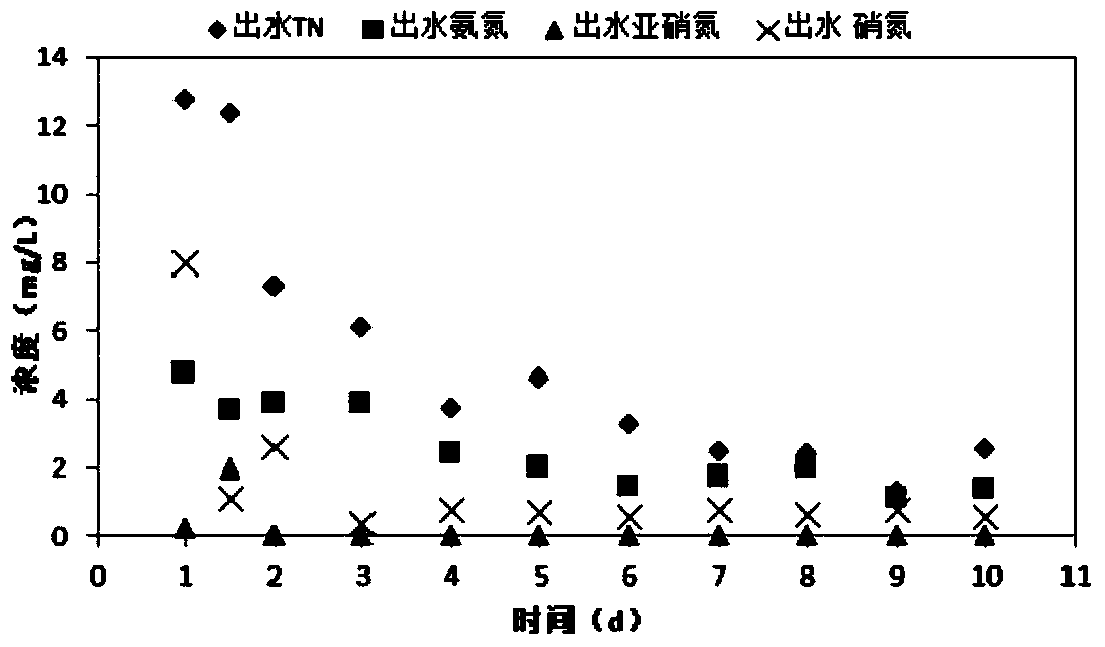

Examples

Embodiment

[0062] Step 10. Place 200g of polyvinyl alcohol aqueous solution in a 2000ml water bath at 90°C, stir mechanically until transparent, add 50ml of ethylene glycol, and add 80ml of 4.7mol / l sulfuric acid.

[0063] Step 20. Stir the above solution evenly at 65°C and 200rpm (10min), then slowly add 80ml of formaldehyde, at the same time rapidly increase the stirring speed to 540rpm, and control the reaction time to 20min.

[0064] Step 30, adding activated carbon particles with a mass fraction of 6.3% as a cell agent and a reinforcing agent, stirring at a speed of 270 rpm for 10 minutes to form a foam solution. The foam solution is poured into the mold and reacted at 65°C for about 20 hours to obtain the foamed polyvinyl formal microbial carrier product, and the foamed polyvinyl formal microbial carrier product is rinsed with clean water.

[0065] The obtained carrier is machined into shape as required to obtain the finished product.

[0066] Density of the foamed polyvinyl forma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com