Method for preparing mesoporous carbon material by catalytically activating sodium lignin sulfonate with organic sylvite

A technology of sodium lignosulfonate and catalytic activation, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as waste of resources, and achieve the effects of convenient production and processing, high specific area, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

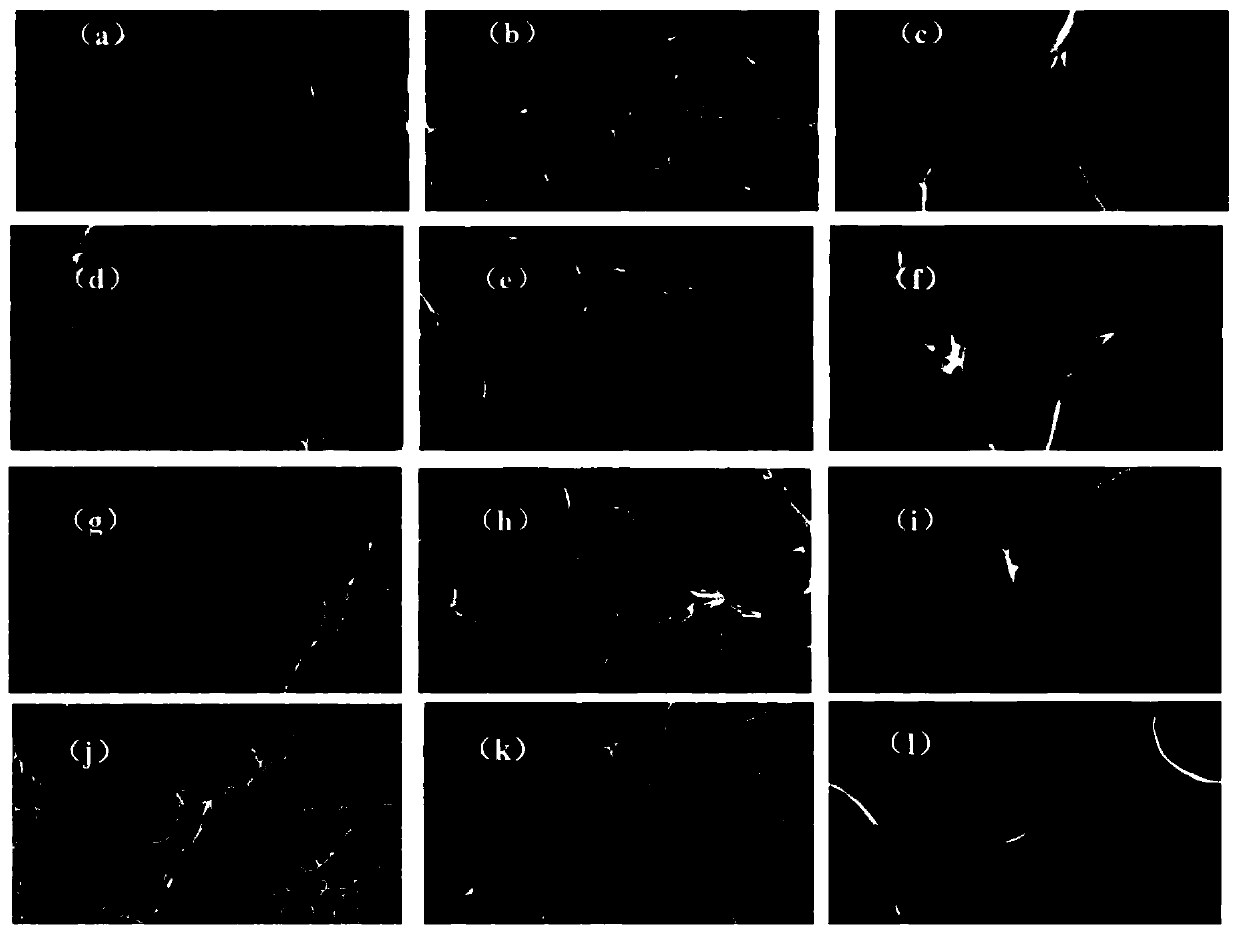

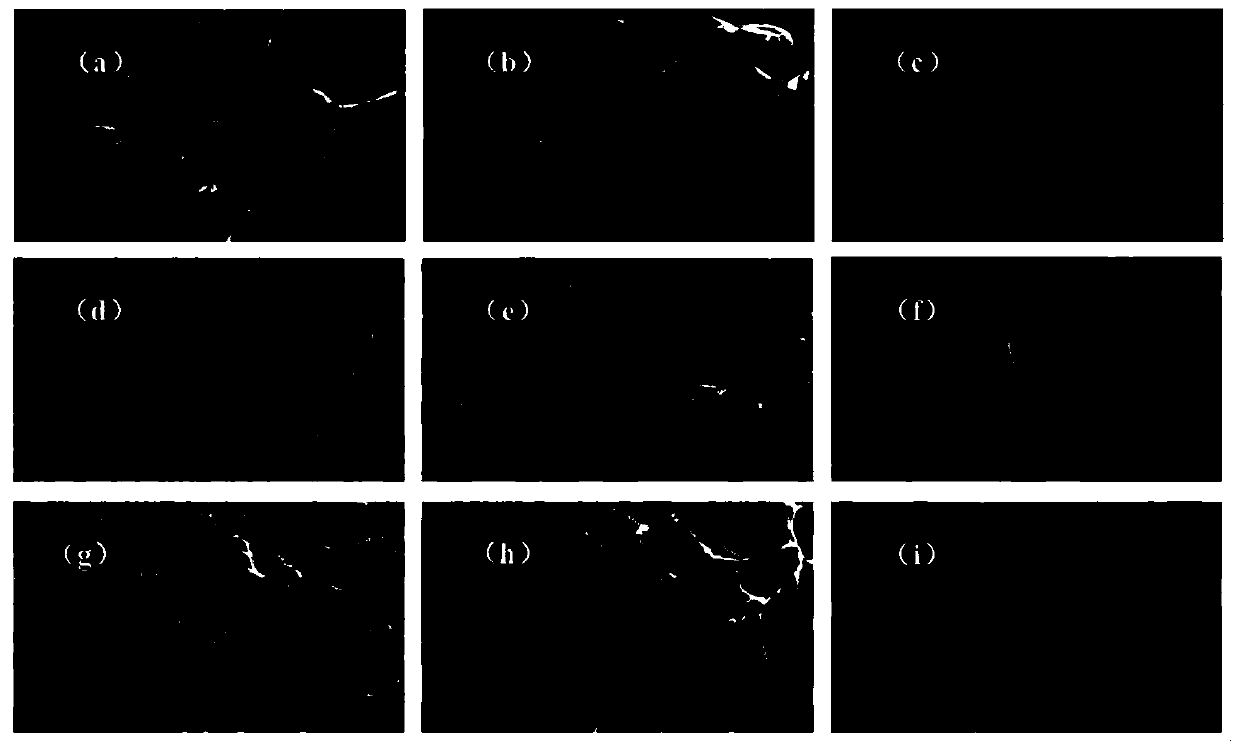

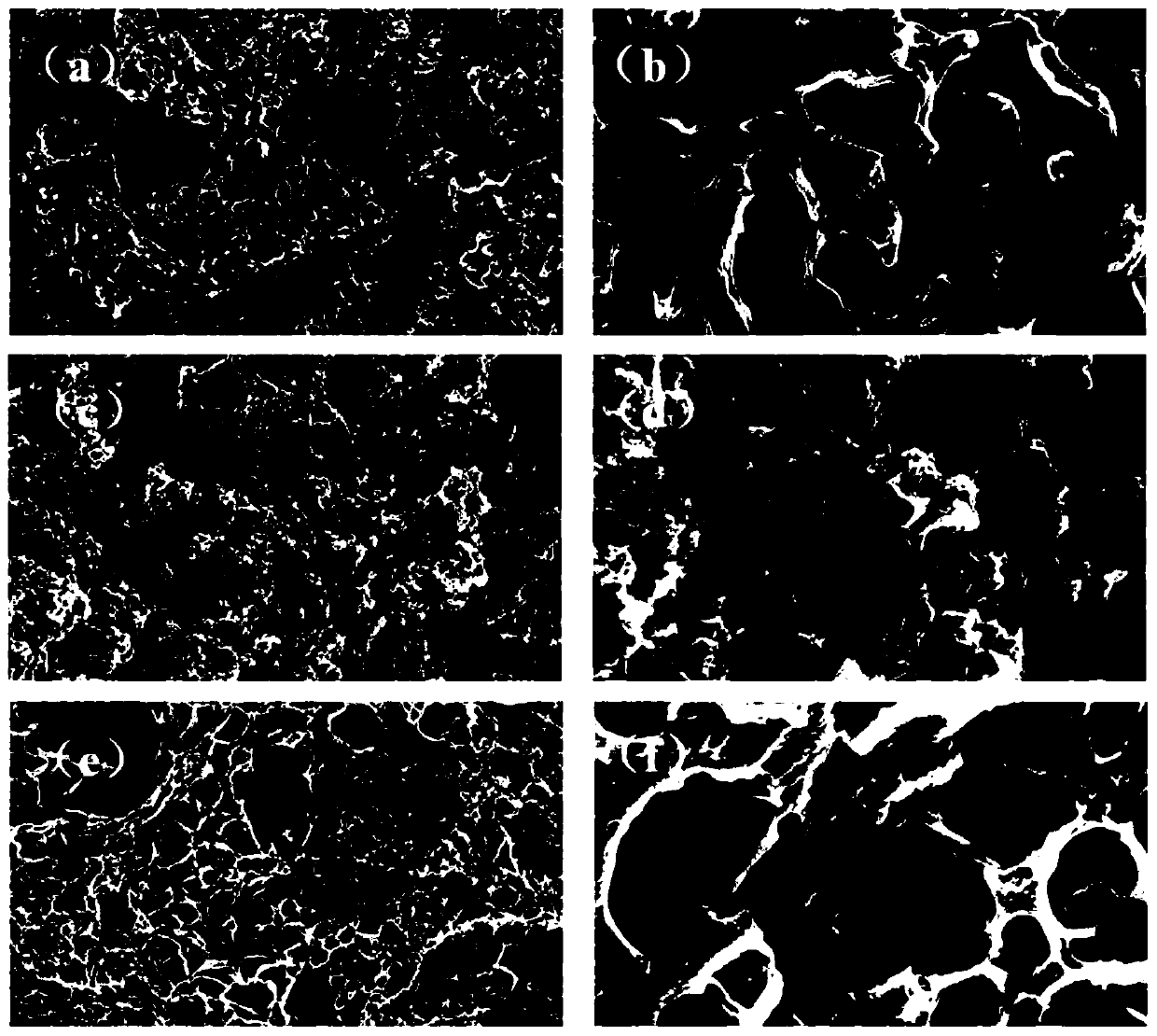

[0022] Example 1: A method for preparing mesoporous carbon material by organic potassium catalyzed activation of sodium lignosulfonate, using a magnetic stirrer with a concentration of 50% potassium tartrate solution and sodium lignosulfonate at an impregnation ratio of 2:1 Mix well, control the pH value of the solution at 6.5, then dry the solution at 155°C with a spray drying device to remove moisture to form a sodium lignosulfonate / potassium tartrate dry powder raw material, and then put the completely dried dry powder raw material into a tube furnace , under a nitrogen atmosphere (that is, the protective gas is nitrogen), the temperature was raised from 25°C to 800°C at a rate of 13°C / min, and activated at a constant temperature at this temperature for 1.8h. After activation, it was lowered to room temperature, and the sample obtained after activation was taken out. Wash with deionized water to remove impurities, then repeatedly wash with deionized water until the pH value ...

Embodiment 2

[0023] Embodiment 2: A method for preparing mesoporous carbon material by organic potassium catalyzed activation of sodium lignosulfonate, using a magnetic stirrer with a concentration of 50% potassium tartrate solution and sodium lignosulfonate with an impregnation ratio of 4:1 Mix evenly, control the pH value of the solution at 7.5, then dry the solution at 160°C with a spray drying device to remove moisture to form a sodium lignosulfonate / potassium tartrate dry powder raw material, and then put the completely dried dry powder raw material into a tube furnace , in a nitrogen atmosphere, the temperature was raised from 35°C to 800°C at a rate of 18°C / min, and activated at this temperature for 1.8h at a constant temperature. After activation, it was lowered to room temperature, and the sample obtained after activation was taken out and washed with deionized water to remove impurities. , and then repeatedly washed with deionized water until the pH value was 7, and finally dried ...

Embodiment 3

[0024] Example 3: A method for preparing mesoporous carbon material by organic potassium catalyzed activation of sodium lignosulfonate, using a magnetic stirrer with a concentration of 50% potassium tartrate solution and sodium lignosulfonate at an impregnation ratio of 3:1 Mix well, control the pH value of the solution at 7, and then use a spray drying device to dry the solution at 160°C to remove moisture to form a sodium lignosulfonate / activator dry powder raw material, and then put the dry powder raw material into a tube furnace, under nitrogen Under the atmosphere, the temperature was raised from 30°C to 800°C at a heating rate of 15°C / min, and activated at this temperature for 1.5 hours at a constant temperature. After activation, it was lowered to room temperature. The deionized water was washed repeatedly until the pH value was 7, and finally dried at 60°C to remove water to obtain a mesoporous carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com