Method for batch preparation of pure phase AlON transparent ceramic powder body

A transparent ceramic and pure-phase technology, which is applied in the field of batch preparation of pure-phase AlON transparent ceramic powder, can solve the problems of unexplained performance of transparent ceramics, unfavorable industrial production, oxidation of AlON powder, etc., and achieve the prevention of raw material pollution and good reaction The effect of activated and refined activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] ① Mixing: Al with an average particle size of 80nm 2 o 3 The mixed powder of analytically pure activated carbon particles was mixed with silicon nitride as the ball milling medium and dehydrated alcohol as the dispersion medium at a speed of 170r / min for 12h, wherein the activated carbon accounted for 5.6wt.% of the total mass of raw materials, and the quality of dehydrated alcohol was 4 times the quality of the raw material, the specific surface area is 253m 2 / g of mixed powder slurry.

[0062] ②Drying: Dry the slurry obtained in step ① on an electric heating plate at 140°C for 1.2h in the air, and pass through a 50-mesh sieve to obtain Al 2 o 3 Mix powder with activated carbon;

[0063] ③Fabrication: Put the mixed powder in a graphite crucible with a radius of 85mm, the powder filling height is 43mm, and the air holes with a diameter of 1.5mm and a spacing of 10mm are preset in the powder;

[0064] ④Pre-vacuumize the sintering furnace: place the graphite crucibl...

Embodiment 2

[0069] Other steps are identical with embodiment 1, difference is:

[0070] Step 1. Mixing: Al with an average particle size of 80nm 2 o 3 The mixed powder of analytically pure activated carbon particles was mixed with silicon nitride as the ball milling medium and dehydrated alcohol as the dispersion medium at a speed of 170r / min for 2h, wherein the activated carbon accounted for 5.6wt.% of the total mass of raw materials, and the quality of dehydrated alcohol was 4 times the quality of the raw material, the specific surface area is 195m 2 / g of mixed powder slurry.

[0071] ②Drying: Dry the slurry obtained in step ① on an electric heating plate at 140°C for 1.2h in the air, and pass through a 50-mesh sieve to obtain Al 2 o 3 Mix powder with activated carbon;

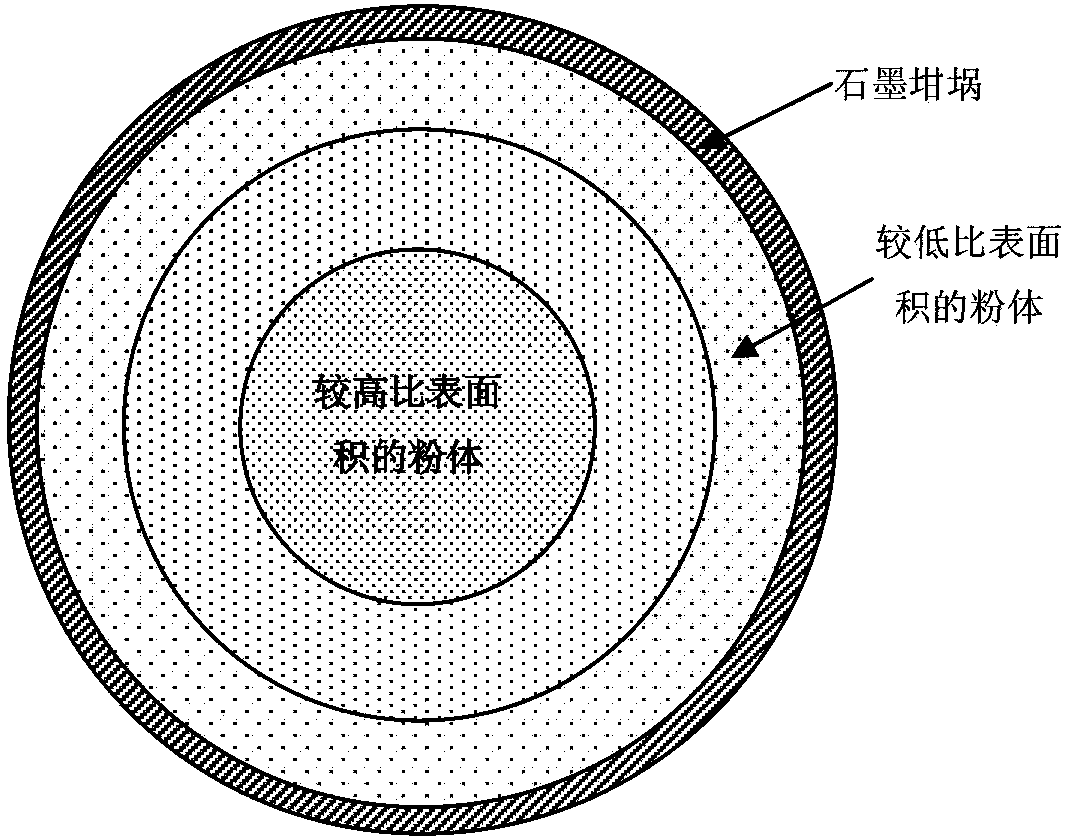

[0072] ③Fabrication: Put the mixed powder in a graphite crucible with a radius of 120mm, the powder filling height is 43mm, and the above-mentioned 195m 2 The mixed powder of / g is placed in the region with a rad...

Embodiment 3

[0075] Other steps are identical with embodiment 1, difference is:

[0076] Step 1. Mixing: Al with an average particle size of 80nm 2 o 3 The mixed powder of analytically pure activated carbon particles was mixed with silicon nitride as the ball milling medium and dehydrated alcohol as the dispersion medium at a speed of 160r / min for 24h, wherein the activated carbon accounted for 5.6wt.% of the total mass of raw materials, and the quality of dehydrated alcohol was 4 times the quality of the raw material, the specific surface area is 177m 2 / g of mixed powder slurry.

[0077] ③Fabrication: Put the mixed powder in a graphite crucible with a radius of 150mm, the powder filling height is 43mm, and the above-mentioned 177m 2 The mixed powder of / g is distributed in the area that the radius is greater than 120mm, and embodiment 2 steps 2. gained 195m 2 The mixed powder of / g is arranged in the area of radius 852 / g of mixed powder is placed in an area with a radius of less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com