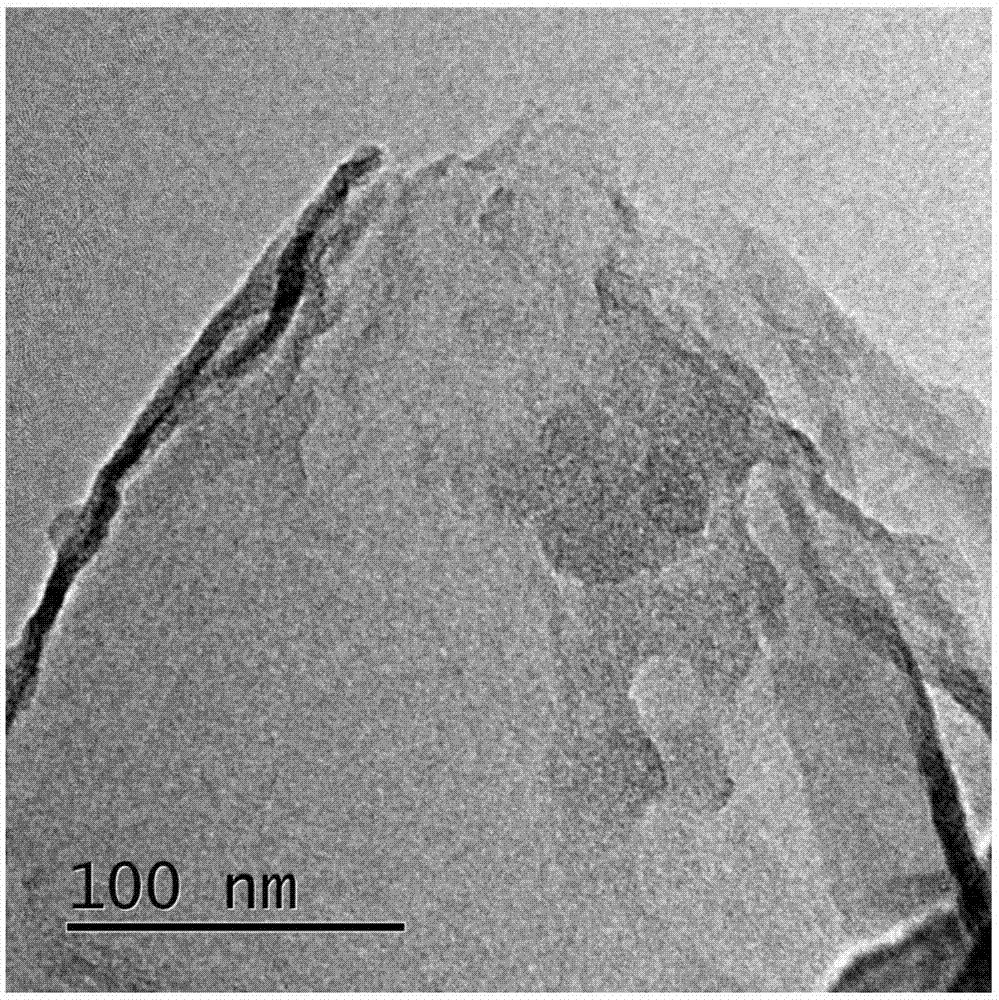

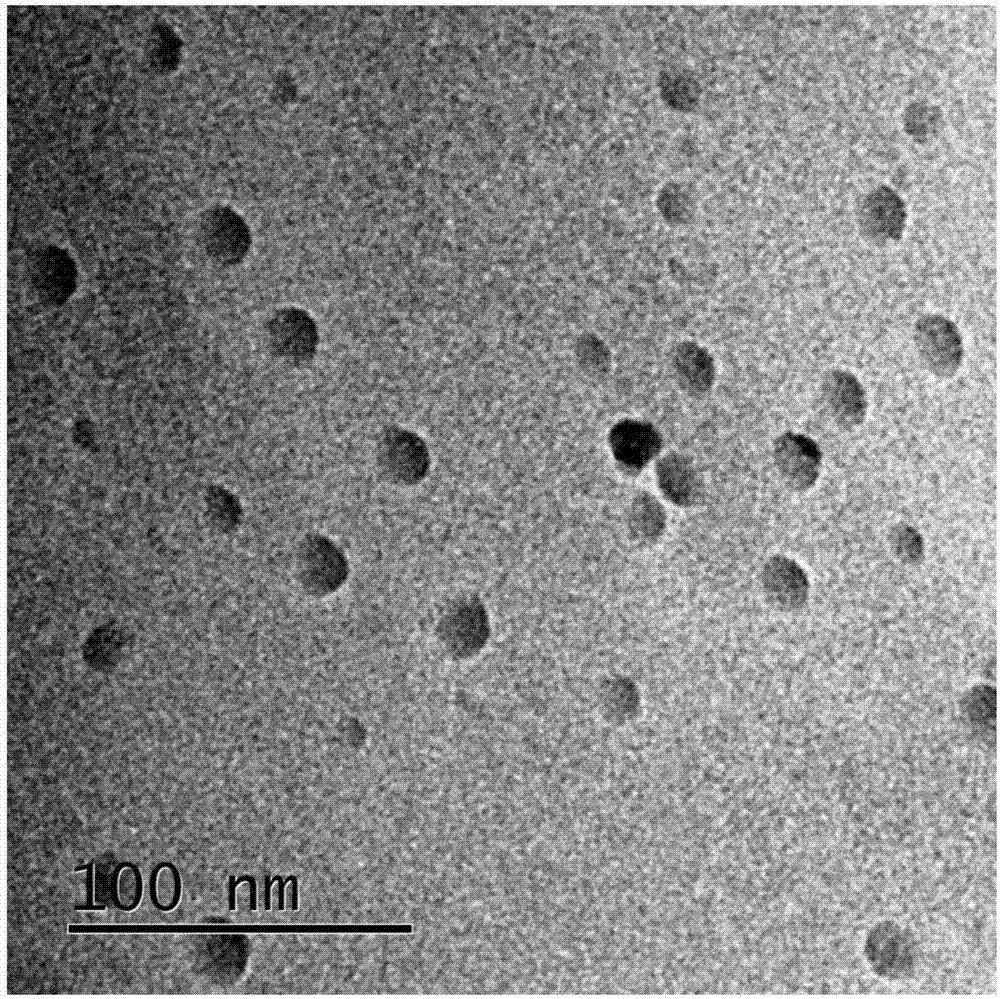

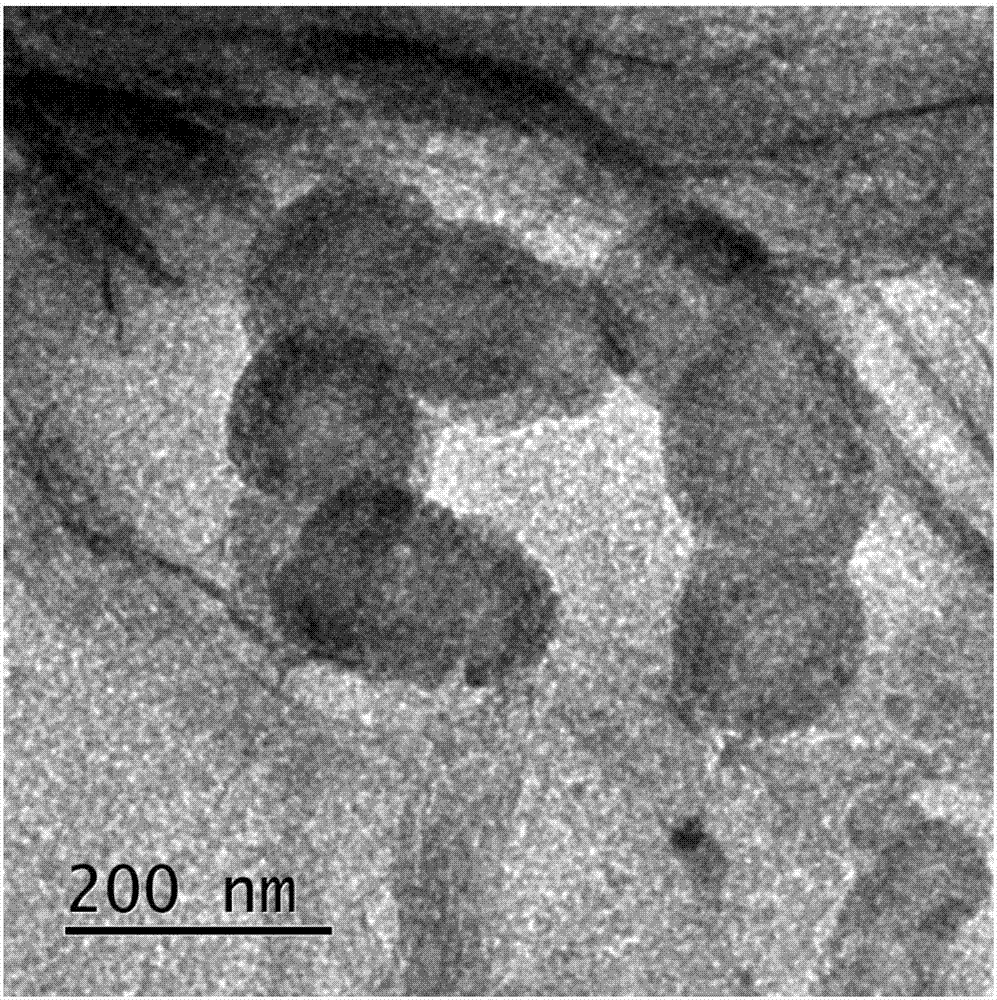

Method for preparing nano mesoporous carbon microsphere-graphene sandwich composite material

A technology of nano-mesoporous and composite materials, applied in the direction of graphene, nano-carbon, hybrid capacitor electrodes, etc., can solve the problems of complex preparation process and high cost, and achieve the effect of simple equipment, low cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1, assemble the complex:

[0033] Accurately weigh 0.03g of graphene oxide in 50mL of 0.1mol / L NaOH aqueous solution (the mass ratio of graphene oxide to NaOH aqueous solution is 1:1673), and ultrasonically disperse to obtain a graphene oxide dispersion; weigh 0.1g of structure directing agent Add CTAB to 40mL 0.1mol / L NaOH aqueous solution (mass ratio of CTAB to NaOH aqueous solution is 1:416), then add 0.3g carbon source AMP (mass ratio of AMP to NaOH aqueous solution is 1:139), and then 1. React for 1 h at a stirring speed of 500 r / min to obtain a mixed liquid of mesoporous carbon precursor, add the graphene oxide dispersion liquid to the mixed liquid of mesoporous carbon precursor and react for 1 h at 20°C with a stirring speed of 600 r / min , assembled into complexes;

[0034] Step 2, aging treatment:

[0035] Put the complex assembled in step 1 into a reaction kettle, heat at 140°C for 48h, then filter and wash with deionized water until neutral, and dry at ...

Embodiment 2

[0040] Step 1, assemble the complex:

[0041]Accurately weigh 0.03g of graphene oxide in 50mL of 0.1mol / L NaOH aqueous solution (the mass ratio of graphene oxide to NaOH aqueous solution is 1:1673), and ultrasonically disperse to obtain a graphene oxide dispersion; weigh 0.2g of structure directing agent Add CTAB to 40mL 0.1mol / L NaOH aqueous solution (mass ratio of CTAB to NaOH aqueous solution is 1:208), then add 0.3g carbon source AMP (mass ratio of AMP to NaOH aqueous solution is 1:139), and then 1. React for 1 hour at a stirring speed of 500r / min to obtain a mesoporous carbon precursor mixture. Add the graphene oxide dispersion to the mesoporous carbon precursor mixture and react for 1 hour at 20°C with a stirring speed of 600r / min. , assembled into complexes;

[0042] Step 2, aging treatment:

[0043] Put the complex assembled in step 1 into a reaction kettle, heat at 140°C for 48h, then filter and wash with deionized water until neutral, and dry at 100°C for 12h to ob...

Embodiment 3

[0048] Step 1, assemble the complex:

[0049] Accurately weigh 0.03g of graphene oxide in 50mL of 0.1mol / L NaOH aqueous solution (the mass ratio of graphene oxide to NaOH aqueous solution is 1:1673), and ultrasonically disperse to obtain graphene oxide dispersion; weigh 0.3g of structure directing agent Add CTAB to 40mL 0.1mol / L NaOH aqueous solution (mass ratio of CTAB to NaOH aqueous solution is 1:139), then add 0.3g carbon source AMP (mass ratio of AMP to NaOH aqueous solution is 1:139), and then 1. React for 1 hour at a stirring speed of 500r / min to obtain a mesoporous carbon precursor mixture. Add the graphene oxide dispersion to the mesoporous carbon precursor mixture and react for 1 hour at 20°C with a stirring speed of 600r / min. , assembled into complexes;

[0050] Step 2, aging treatment:

[0051] Put the complex assembled in step 1 into a reaction kettle, heat at 140°C for 48h, then filter and wash with deionized water until neutral, and dry at 100°C for 12h to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com