Method for preparing porous carbon material by using non-nano zinc oxide or zinc hydroxide and porous carbon material

A porous carbon material, nano-zinc oxide technology, applied in the direction of nano-carbon, etc., can solve problems such as strong corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] a. Weigh 2g of glucose and 2.7g of common commercial non-nanometer zinc oxide, and ball mill for 10 minutes at a speed of 100 rpm to obtain a uniform solid powder;

[0064] b. Transfer A in step a to a quartz crucible, put it in a tube furnace, and then pass nitrogen as a protective gas to raise the temperature of the tube furnace to 500 °C at a rate of 5 °C / min, then cool naturally to room temperature and grind Get B evenly;

[0065] c. B in step b is washed and dried with an aqueous acid solution to obtain a porous carbon-carbon material;

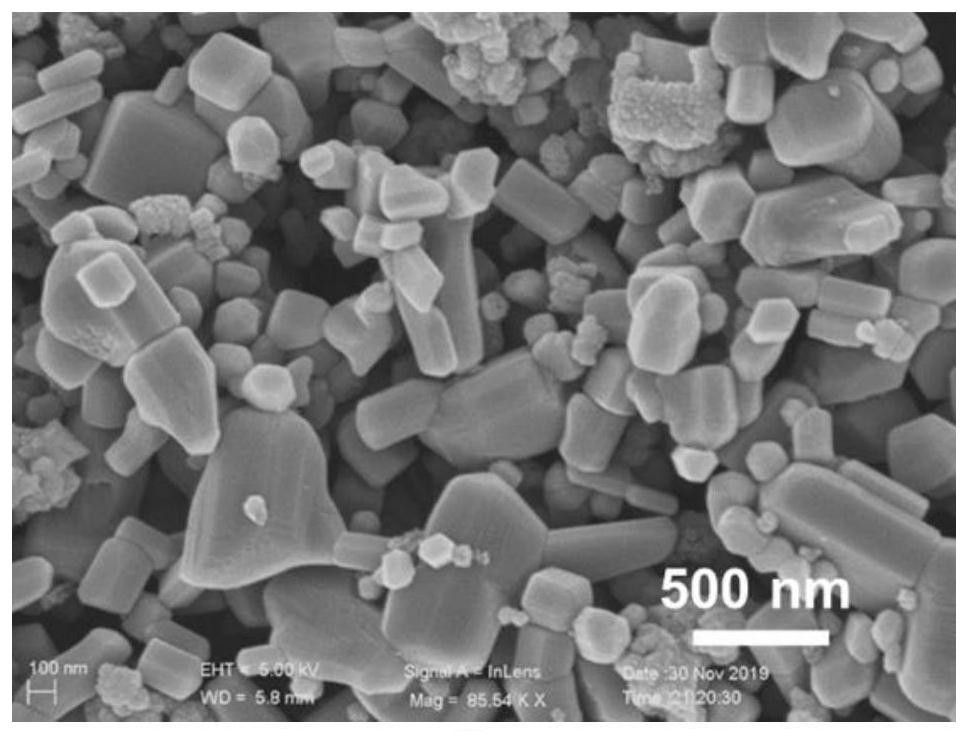

[0066] figure 1 It is a scanning electron micrograph of common commercial non-nanometer zinc oxide used in the embodiment of the present invention 1;

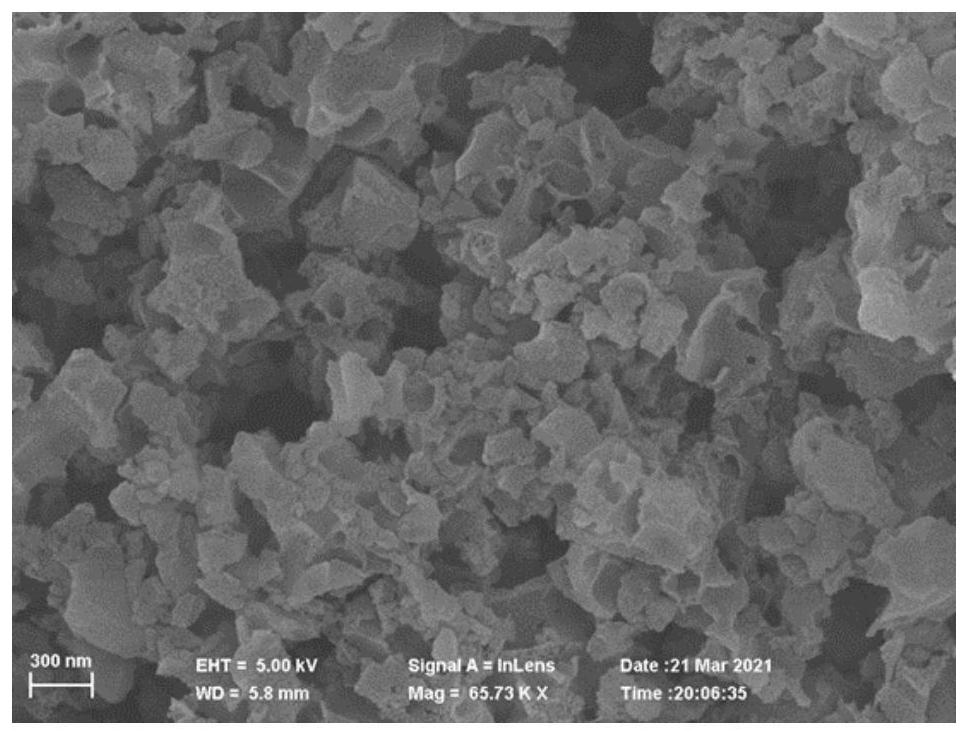

[0067] figure 2 The scanning electron micrograph of the porous carbon nanomaterial prepared for Example 1 of the present invention;

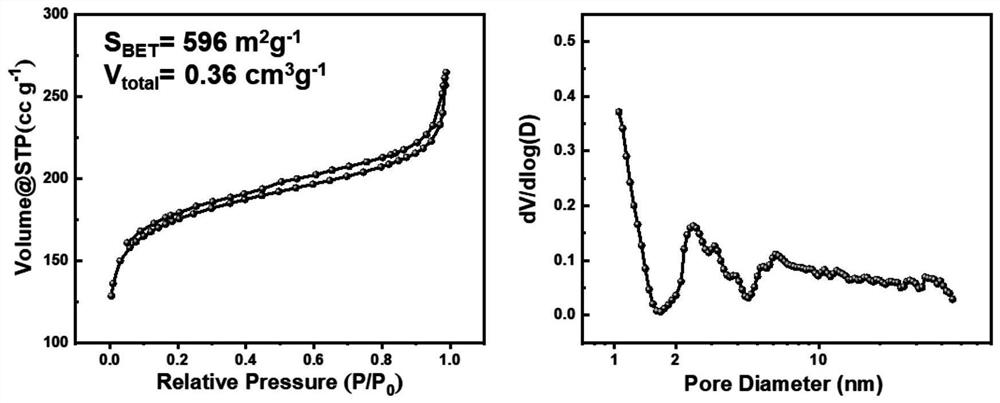

[0068] image 3 Nitrogen adsorption and desorption curves and pore size distribution diagrams of porous carbon nanomaterials prepared in Exampl...

Embodiment 2

[0079] a. Weigh 2g of glucose and 3.6g of common commercial non-nanometer zinc oxide into a mortar, and grind for 10min with a grinding pestle to obtain a uniform solid powder;

[0080] b. Transfer the solid powder in step a to a quartz crucible, put it in a tube furnace, and then pass nitrogen as a protective gas to raise the temperature to 1000°C at a rate of 5°C / min and keep it for 2h, and then naturally cool to room temperature to obtain Porous carbon materials;

[0081] Figure 7 It is a scanning electron micrograph of the porous carbon material obtained by grinding and mixing glucose and common commercial non-nanometer zinc oxide in Example 2 of the present invention;

[0082] Figure 8 It is the nitrogen adsorption-desorption curve and pore size distribution diagram of the porous carbon material obtained by grinding and mixing glucose and common commercial non-nanometer zinc oxide in Example 2 of the present invention.

[0083] Depend on Figure 7 and Figure 8 It ...

Embodiment 3

[0085] a. Disperse 2g of glucose and 2.7g of common commercial non-nanometer zinc oxide in 50mL of water, stir for 5h and then perform rotary evaporation to remove the solvent to obtain mixture A;

[0086] b. Transfer A in step a to a quartz crucible, put it in a tube furnace, and then pass nitrogen as a protective gas to raise the temperature of the tube furnace to 500 °C at a rate of 5 °C / min and keep it for 2 hours, then naturally cool to room temperature Grind evenly to obtain B;

[0087] c. B in step b is washed with an aqueous acid solution and then dried to obtain a porous carbon-carbon material;

[0088] Figure 9 It is a scanning electron micrograph of the porous carbon material obtained by mixing glucose and common commercial non-nanometer zinc oxide in the liquid phase in Example 3 of the present invention;

[0089] Figure 10 It is the nitrogen adsorption-desorption curve and pore size distribution diagram of the porous carbon material obtained from glucose and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com