Preparation method, product and application of ferroferric oxide/nitrogen doped graphene composite material

A nitrogen-doped graphene, ferric oxide technology, applied in nanotechnology, electrochemical generators, active material electrodes for materials and surface science, etc., can solve the problem that ferric tetroxide particles are difficult to anchor, It does not have the problems of 3D structure configuration and complex synthesis method, and achieves the effects of good three-dimensional pore structure channel, cheap raw materials and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

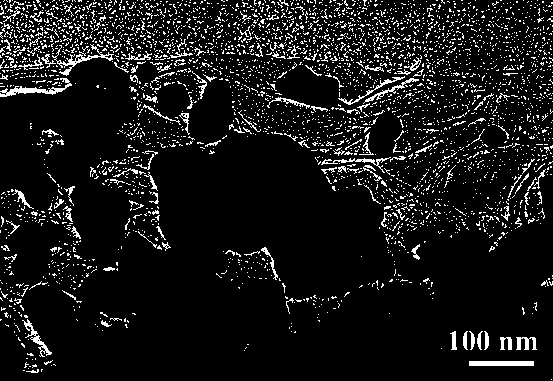

Image

Examples

Embodiment 1

[0022] a. Preparation of nitrogen-doped graphene oxide dispersion: Take 50 mL of graphene oxide dispersion prepared by the Hummers method in a beaker, take 10 mg of cyanamide as nitrogen source and slowly add to the dispersion and keep stirring, then add Distilled water, adjust the pH of the solution to 10; add the graphene oxide dispersion of nitrogen source at 140 o Heating and stirring at C temperature for 5 h, the stirring speed was controlled at 8000 rpm, then the solution was transferred to a polytetrafluoroethylene reactor, at 140 o Airtight and heat preservation at C temperature for 4 h;

[0023] b. Preparation of FeOOH / GO material: Weigh 1.0 g of iron acetate and add it to 50 mL of the nitrogen-doped graphene oxide dispersion, and stir continuously for 1 hour to obtain a stable brown suspension; Sealed in a polytetrafluoroethylene reactor, at 180 o Under the temperature of C for 12 hours of hydrothermal reaction, during this process, iron acetate is further hydrolyz...

Embodiment 2

[0026] a. Preparation of nitrogen-doped graphene oxide dispersion: Take 50 mL of graphene oxide dispersion prepared by the Hummers method in a beaker, take 10 mg of urea as a nitrogen source and slowly add it to the dispersion and keep stirring, then add distilled water, Adjust the pH of the solution to 12; add the graphene oxide dispersion of nitrogen source at 140 o Heating and stirring at C temperature for 5 h, the stirring speed was controlled at 8000 rpm, then the solution was transferred to a polytetrafluoroethylene reactor, at 140 o Airtight and heat preservation at C temperature for 4 h;

[0027] b. Preparation of FeOOH / GO material: Weigh 1.0 g of ferric nitrate and add it to 50 mL of the nitrogen-doped graphene oxide dispersion, and stir continuously for 1 hour to obtain a stable brown suspension; Sealed in a polytetrafluoroethylene reactor, at 180 o After hydrothermal reaction at C temperature for 12 hours, ferric nitrate is hydrolyzed into FeOOH and dispersed on t...

Embodiment 3

[0030] a. Preparation of nitrogen-doped graphene oxide dispersion: Take 50 mL of graphene oxide dispersion prepared by the Hummers method in a beaker, take 10 mg of dicyandiamide as nitrogen source and slowly add to the dispersion and keep stirring, then add Distilled water, adjust the pH of the solution to 12; add the graphene oxide dispersion of nitrogen source at 140 o Heating and stirring at C temperature for 5 h, the stirring speed was controlled at 8000 rpm, then the solution was transferred to a polytetrafluoroethylene reactor, at 140 o Airtight heat preservation at C temperature for 4 h;

[0031] b. Preparation of FeOOH / GO material: Weigh 1.0 g of iron acetate and add it to 50 mL of the nitrogen-doped graphene oxide dispersion, and stir continuously for 1 hour to obtain a stable brown suspension; Sealed in a polytetrafluoroethylene reactor, at 190 o Under the temperature of C for 12 hours of hydrothermal reaction, during this process, iron acetate is hydrolyzed into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com