Catalyst prepared by using aryl-containing s-triazine cyclic polymer as precursor as well as preparation method and application thereof

A technology of polymerization catalyst and s-triazine, which is applied to electrical components, battery electrodes, circuits, etc., can solve problems such as inability to produce in batches, and achieve the effects of unique preparation process, low price and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

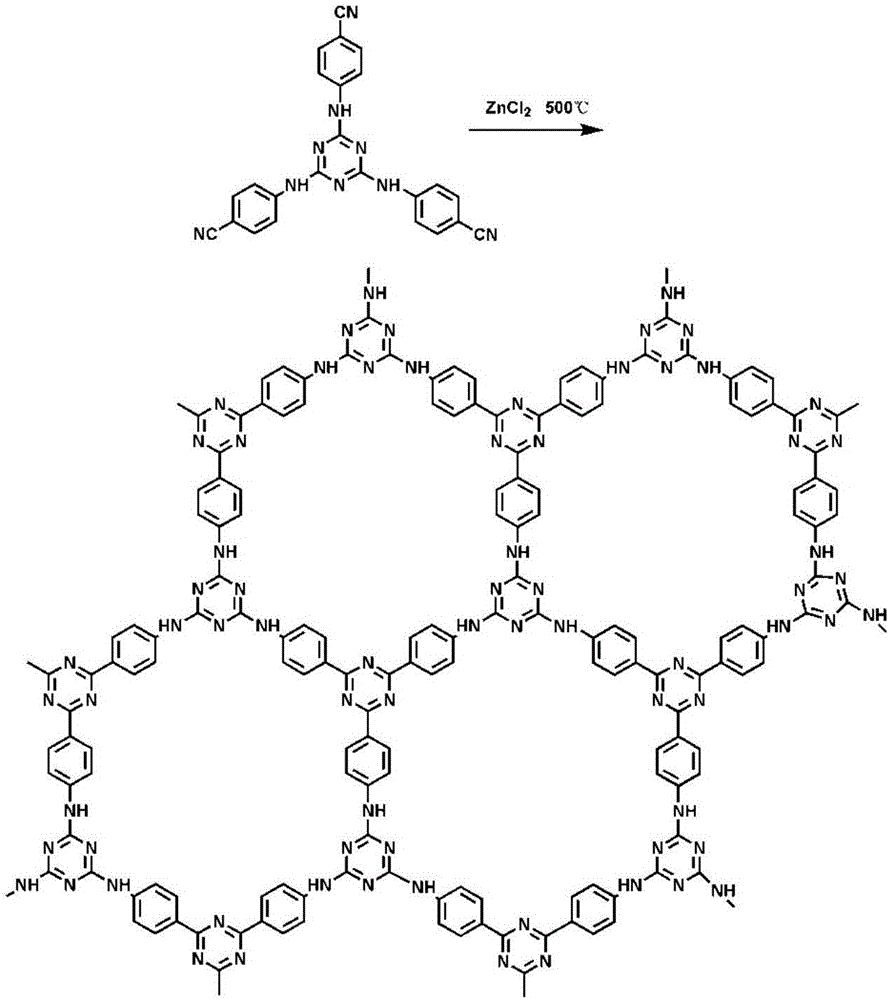

[0057] The preparation of the catalyst of the present invention requires the cyclization of the cyano group to generate a triazine compound. Since the carbon-nitrogen triple bond of the cyano group is relatively stable, in general, the cyclization reaction of the cyano group requires high temperature and high pressure, or the presence of a catalyst. conduct. ZnCl 2 3. Trifluoromethanesulfonic acid can catalyze the trimerization and cyclization reaction of cyano groups under normal pressure conditions, with high efficiency and convenient operation. The reaction conditions of the two catalysts are different when used, and the use of ZnCl 2 The temperature is slightly higher, at 400-600°C, the reaction time is 40-96h, the effect is better; when using trifluoromethanesulfonic acid, the required temperature is lower, about 100-200°C, and the reaction time is shorter, at 1-6h The product can be obtained within.

[0058] Preferably, in step 1), after the reaction is completed, the...

Embodiment 1

[0070] A preparation of an oxygen reduction catalyst prepared from a precursor containing an aryl-s-triazine ring polymer comprises the following steps:

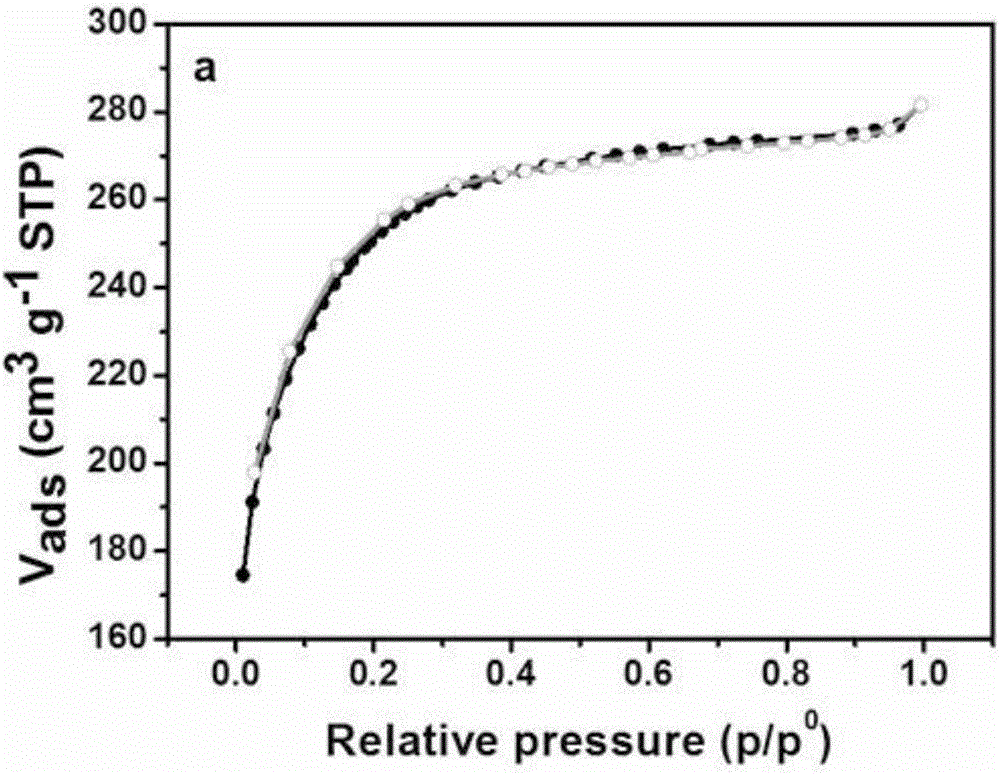

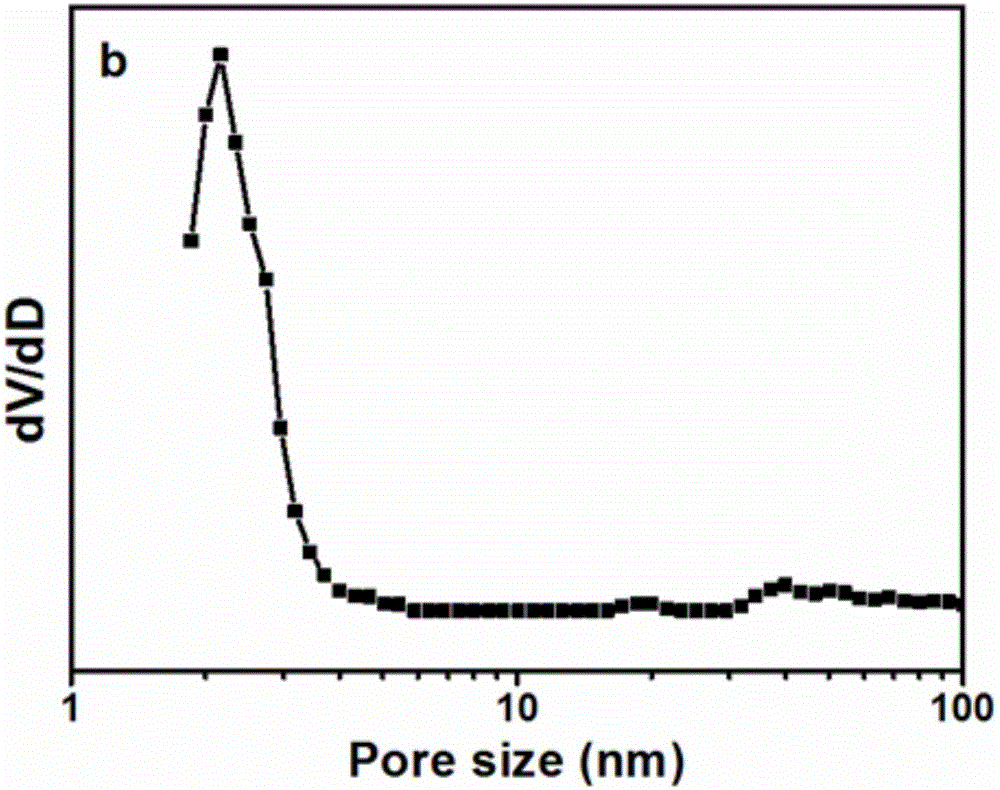

[0071] 1) Preparation of poly(2,4,6-tris(p-cyanoaniline)-1,3,5-triazine): add 429 mg (1 mmol) 2,4,6-tris(p-cyanoaniline) to the sealed tube phenylamino)-1,3,5-triazine, 613.4mg (5mmol) of zinc chloride, and a small amount of absolute ethanol for ultrasonic dispersion. Then spin dry the ethanol, seal the tube and place it in a muffle furnace at 500°C for 40 hours to react to obtain a polymer. After the reaction is complete, put the polymer in a 500ml flask, add 200ml of distilled water, stir for 1h, then wash at 90°C for 12h with stirring, filter, then wash with water until neutral, then wash with dimethyl sulfoxide and acetone in turn, and vacuum dry The obtained polymer is marked as: TIF-3, and its synthetic route is as follows figure 1 Shown; its nitrogen adsorption-desorption curve and pore structure distribution are as...

Embodiment 2

[0074] A preparation of an oxygen reduction catalyst prepared from a precursor containing an aryl-s-triazine ring polymer comprises the following steps:

[0075] 1) Preparation of poly(2,4-bis(p-cyanoaniline)-1,3,5-triazine): add 313 mg (1 mmol) 2,4-bis(p-cyanoaniline) to the sealed tube -1,3,5-triazine, 1801mg (12mmol) trifluoromethanesulfonic acid, uniformly dispersed by ultrasonic. After sealing the tube, place it at 110° C. for 10 h to obtain a polymer. After the reaction is complete, put the polymer in a 500ml flask, add 200ml of distilled water, stir for 1h, then wash at 90°C for 12h under stirring, then wash with water until neutral, then wash with dimethyl sulfoxide and acetone in turn, and dry in vacuo to obtain a polymer material, marked as: TIF-2, its nitrogen adsorption-desorption curve and pore structure distribution are as follows Figure 7 , Figure 8 shown.

[0076] 2) Preparation of an oxygen reduction catalyst prepared with poly(2,4-bis(p-cyanoaniline)-1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com