Fe-doped walnut shell activated carbon for treating dye wastewater as well as preparation method and application of activated carbon

A technology for dye wastewater and walnut shells, which is applied in energy wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of slow adsorption rate, difficulty in meeting production needs, poor effect, etc., and achieve fast adsorption rate and reduce Remarkable effect on treatment cost and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

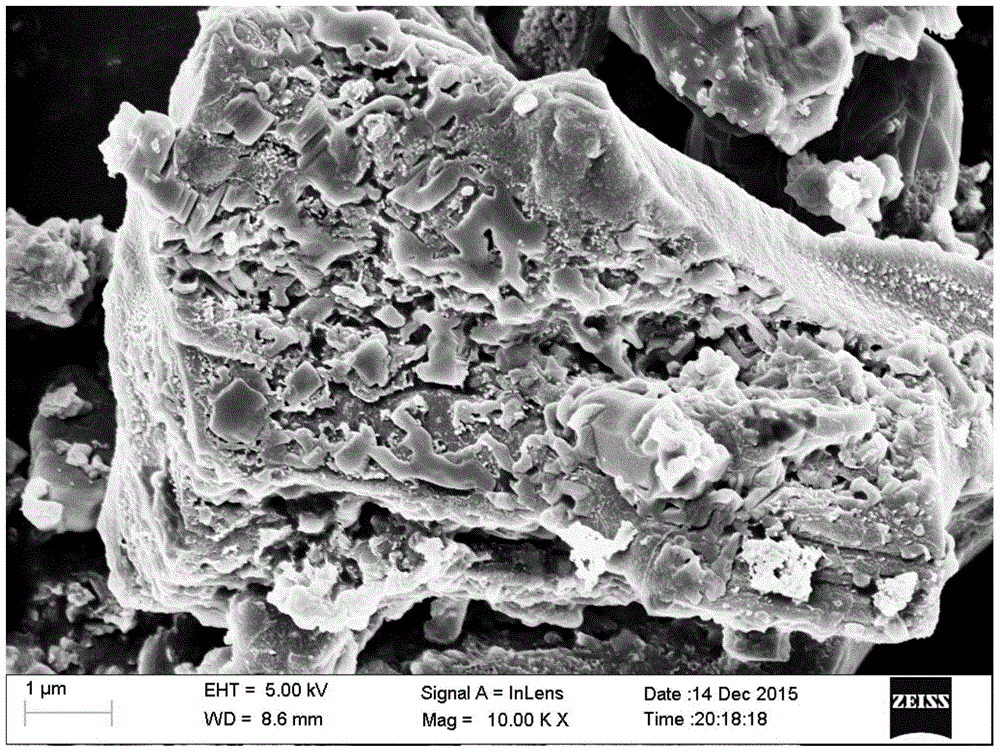

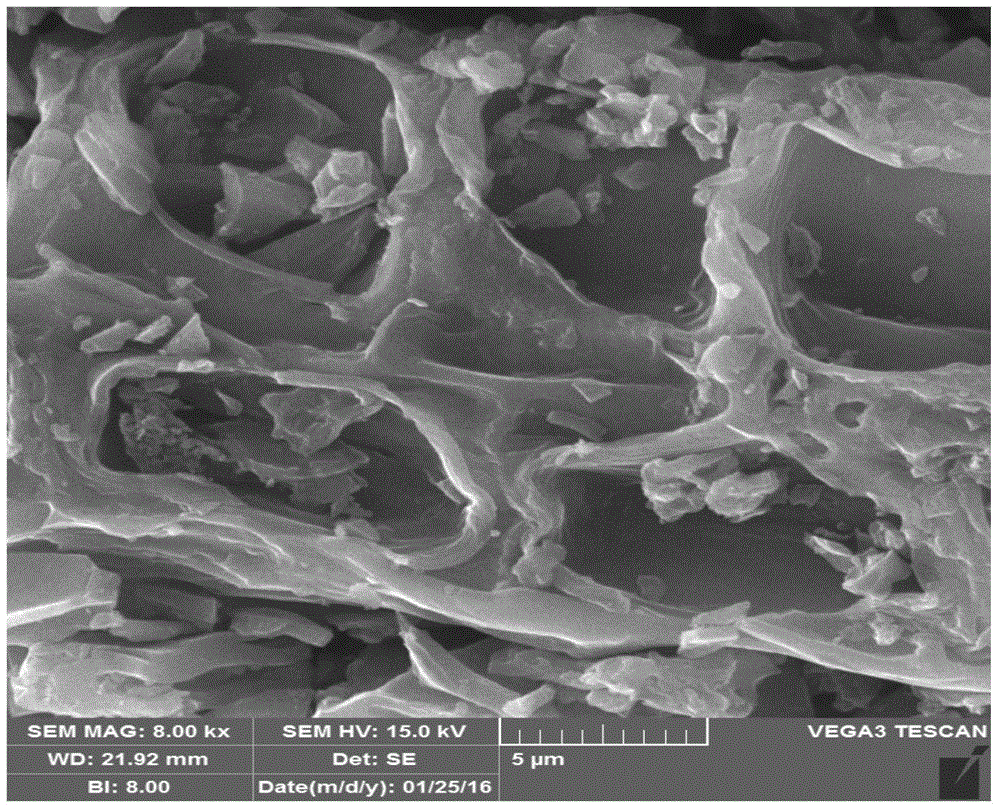

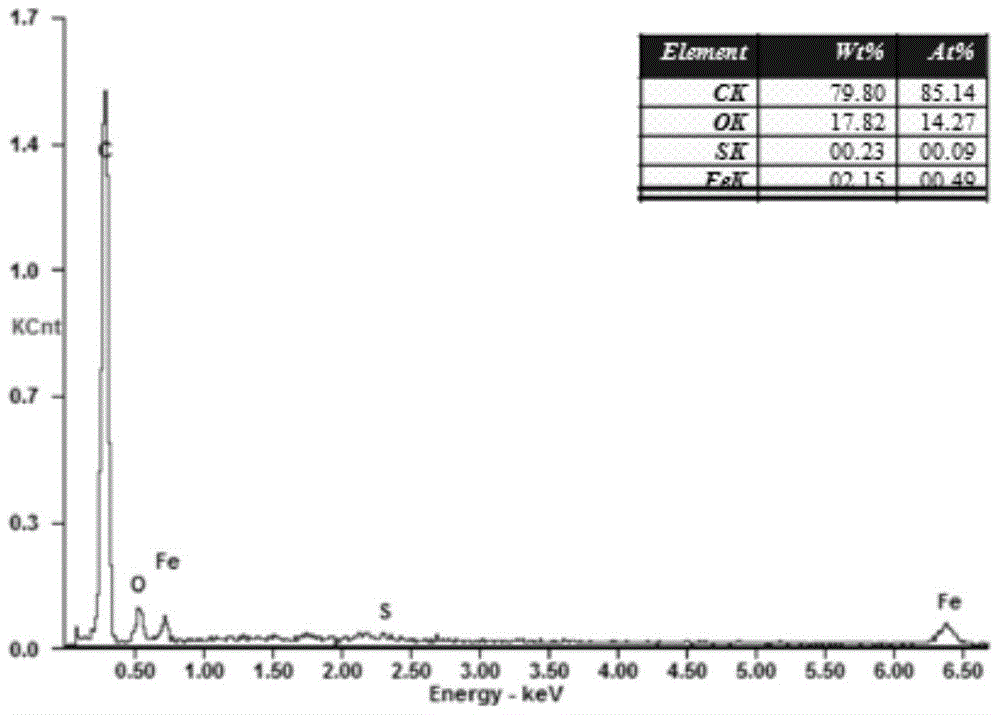

Image

Examples

Embodiment 1

[0045] A preparation method for Fe-doped walnut shell activated carbon, comprising the following steps:

[0046] (1) Acid treatment: Grind and sieve walnut shells, take walnut shell powder larger than 100 mesh, and dry at 110° C. for 24 hours. Weigh 5 g of the dried walnut shell powder, add it to a mixed solution of hydrochloric acid and hydrofluoric acid with a mass fraction of 5%, heat it in a water bath at 25°C, stir it with a magnetic force at a speed of 260 rpm / min, and stir it for 2 hours for washing. Suction filtration until the filtrate is neutral. The filter cake was dried in an electric blast drying oven at 120°C for 12 hours to obtain a walnut shell pickling product.

[0047] (2) Inorganic salt treatment: Take 2g of the walnut shell pickling product, add it to 200mL of 10mmol / L ferrous ammonium sulfate solution, heat in a water bath at 25°C, stir magnetically at a speed of 260rpm / min for 12h, and then mix the obtained The solution was rotary evaporated at 80°C for...

Embodiment 2

[0066] The preparation method of the Fe-doped walnut shell activated carbon of the present embodiment may further comprise the steps:

[0067] The preparation steps are basically the same as in Example 1, except that in step (2), the concentration of the ferrous ammonium sulfate solution is 20mmol / L, and all the other steps are the same.

[0068] The Fe-doped walnut shell activated carbon obtained in Example 2 was adsorbed on the methylene blue solution of 100mg / L~600mg / L under the same conditions as in Example 1. The results showed that the maximum adsorption capacity of Fe-doped walnut shell activated carbon to methylene blue solution was lower than 400mg / g.

Embodiment 3

[0070] The preparation method of the Fe-doped walnut shell activated carbon of the present embodiment may further comprise the steps:

[0071] The preparation steps are the same as in Example 1, except that in step (2), the concentration of ammonium ferrous sulfate solution is 5mmol / L, and all the other steps are the same.

[0072] The Fe-doped walnut shell activated carbon obtained in Example 3 was adsorbed on the methylene blue solution of 100mg / L~600mg / L under the same conditions as in Example 1. The results showed that the maximum adsorption capacity of Fe-doped walnut shell activated carbon to methylene blue solution was 491.327mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com