Process for producing ferrous iron titanium cyanide with spherule silica gel as carrier

A technology of titanium potassium ferrocyanide and potassium ferrocyanide, which is applied in the field of material preparation and radioactive wastewater treatment, and can solve the problems of difficult ferrocyanide granulation, low specific surface area, and low particle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

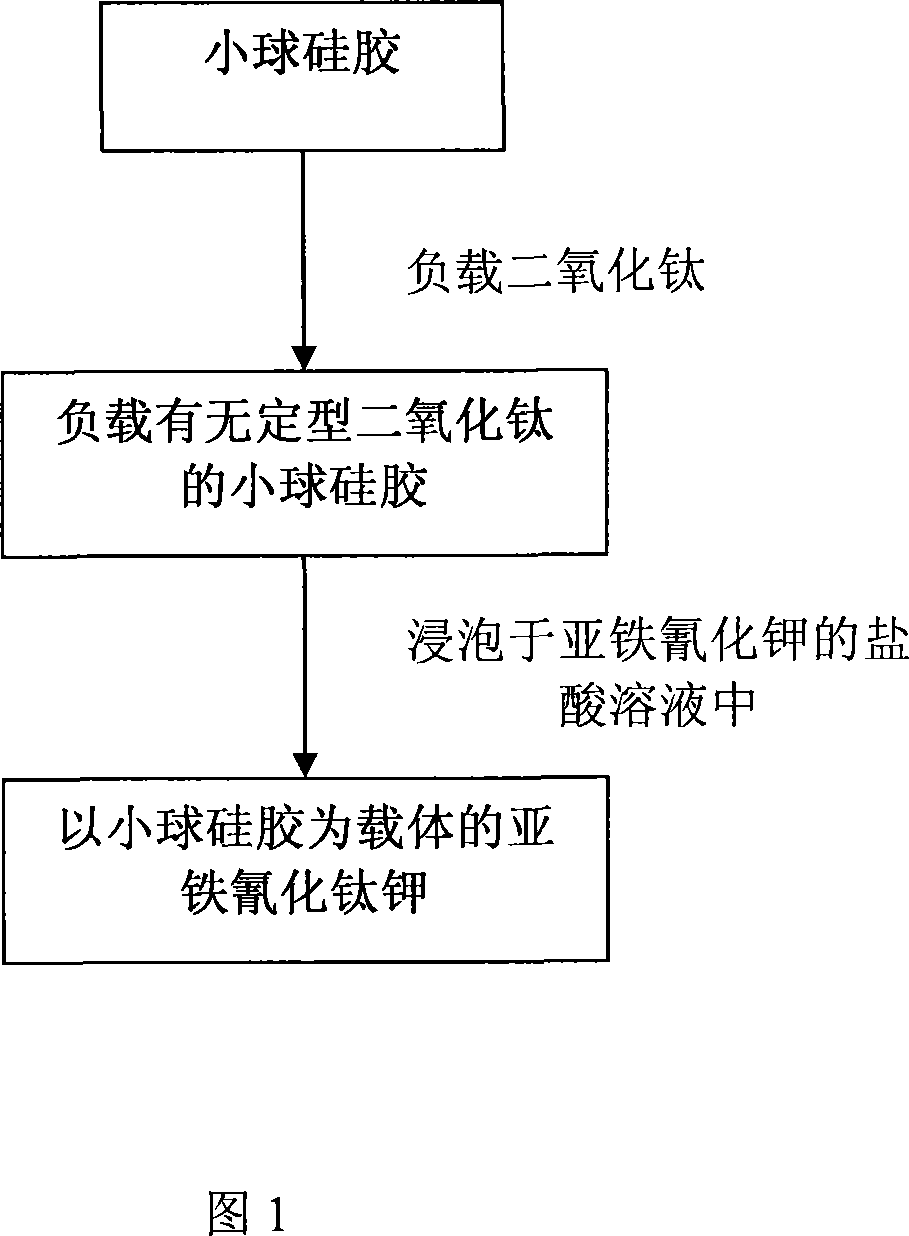

[0021] The preparation method of titanium potassium ferrocyanide provided by the present invention is the carrier of bead silica gel, and its concrete processing steps are as follows:

[0022] 1) Loading amorphous titanium dioxide in the microsphere silica gel channel

[0023]Dissolve tetrabutyl titanate in an organic solvent, the volume ratio of tetrabutyl titanate to organic solvent is 1:5-20; add small balls of silica gel into the organic solvent, the quality of the small balls of silica gel and the titanic acid in the system The mass ratio of tetrabutyl ester is 1:0.85~4.3; Heating to reflux under the protection of nitrogen, the reaction temperature is controlled at the boiling point of the organic solvent used, after 2~24 hours, filter out the silica gel of the pellets and wash them with n-hexane; Dry at 80-100°C in the atmosphere to constant weight to obtain white or light yellow spherical silica gel loaded with amorphous titanium dioxide; the specific surface of the sph...

Embodiment 1

[0028] 10g of coarse-porous pellet silica gel, its specific surface is 184.9m 2 / g, the pore volume is 0.565mL / g, and the average pore diameter is 12.23nm. Wash the silica gel pellets in water, dry them at 90°C for 10 hours, add 8.5g tetrabutyl titanate and 170mL cyclohexane, heat and reflux at 80°C under the protection of nitrogen, and filter the pellets out after 2 hours of reaction. It was dried at 80°C until constant weight, and the loading amount of titanium dioxide was 2% (mass). Then immerse the spherical silica gel loaded with titanium dioxide in 100mL of potassium ferrocyanide hydrochloric acid solution, the concentration of potassium ferrocyanide is 1M, the concentration of hydrochloric acid is 1M, react under stirring for 24hr, and then fully wash with deionized water, A dark blue titanium potassium ferrocyanide / spherical silica gel hybrid material is obtained, and the loading amount of the potassium titanium ferrocyanide is 4% (mass).

Embodiment 2

[0030] 10g of coarse-porous pellet silica gel, its specific surface is 184.9m 2 / g, the pore volume is 0.565mL / g, and the average pore diameter is 12.23nm. Wash the silica gel pellets in water, dry them at 90°C for 10 hours, add 43g of tetrabutyl titanate and 215mL of n-hexane, heat and reflux at 78°C under the protection of nitrogen, filter the pellets out after 24 hours of reaction, and put them in the air for 80 It was dried at ℃ to constant weight, and its loading capacity of titanium dioxide was 8% (mass). Then immerse the spherical silica gel loaded with titanium dioxide in 150mL potassium ferrocyanide hydrochloric acid solution, the concentration of potassium ferrocyanide is 0.5M, the concentration of hydrochloric acid is 1M, react under stirring for 24hr, and then fully wash with deionized water , to obtain a black blue titanium potassium ferrocyanide / small ball silica gel hybrid material, the loading of potassium titanium ferrocyanide is 23% (mass).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com