Catalytic particle electrode used for removing refractory organics and ammonia nitrogen from wastewater and preparation method and application thereof

A technology of refractory organic matter and particle electrodes, which is applied in the field of catalytic particle electrodes and its preparation, can solve the problems of particle electrodes without too much consideration, difficult to remove at the same time, single treatment target, etc., achieve stable treatment effect and increase service life , high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

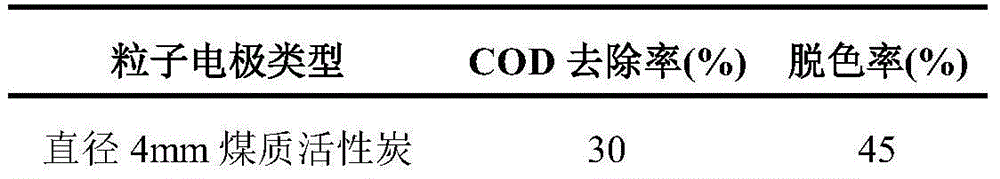

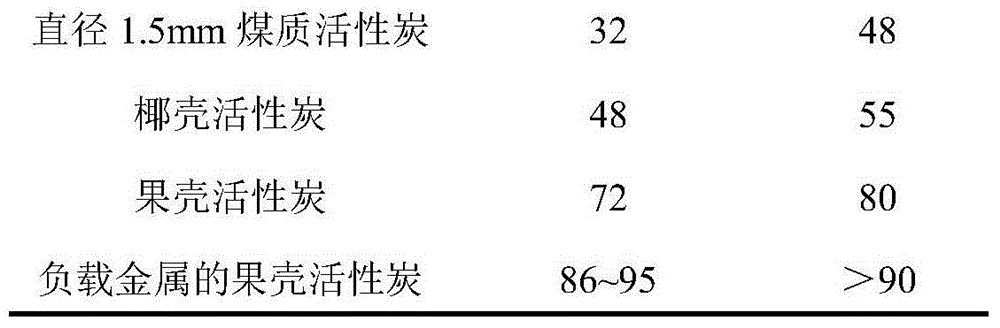

[0030] The catalytic particle electrode material of this example includes nutshell activated carbon with a diameter of 2 to 3 mm and an active metal component. The content of the metal component is 2.5 wt% of the total mass of the activated carbon. The preparation method includes the following steps:

[0031] Take a certain amount of husk activated carbon with a diameter of 2 to 3 mm, wash it with deionized water repeatedly until the pH is around 7, and dry it at 80 ℃ for 6 hours, and then soak the husk activated carbon in 1.5 times the volume of 1mol / L dilute In nitric acid solution, boiled for 25 minutes, then washed with deionized water until the pH value was about 7, then ultrasonically cleaned for 25 minutes, and dried at 103°C for 4 hours. Then the modified nutshell activated carbon is immersed in an equal volume of 0.5mol / L metal salt solution (the mole percentage of each metal active component is: cobalt 50%, iron 40%, manganese 5%, Nickel is 5%, and the total mole percen...

Embodiment 2

[0034] The catalytic particle electrode material of this example includes nutshell activated carbon with a diameter of 4 to 5 mm and an active metal component. The content of the metal component is 1.9 wt% of the total mass of the activated carbon. The preparation method includes the following steps:

[0035] Take a certain amount of husk activated carbon with a diameter of 4~5mm, wash it with deionized water repeatedly until the pH value is around 7, and dry it at 60℃ for 8h, and then soak the husk activated carbon in 1.5 times the volume of 1mol / L dilute In a nitric acid solution, boiled for 20 minutes, then washed with deionized water until the pH value was about 7, then ultrasonically washed for 25 minutes, and dried at 103°C for 5 hours. Then the modified nutshell activated carbon is immersed in an equal volume of 0.5mol / L metal salt solution (the mole percentage of each metal active component is: cobalt 55%, iron 35%, manganese 5%, Nickel is 5%, and the total mole percentag...

Embodiment 3

[0038] The catalytic particle electrode material of this example includes nutshell activated carbon with a diameter of 1 to 3 mm and an active metal component. The content of the metal component is 1.6 wt% of the total mass of the activated carbon. The preparation method includes the following steps:

[0039] Take a certain amount of nutshell activated carbon with a diameter of 1~3mm, wash it with deionized water repeatedly until the pH value is around 7, and dry it at 80℃ for 8h, and then soak the nutshell activated carbon in 2.5 times the volume of 1mol / L dilute In a nitric acid solution, boiled for 30 minutes, then washed with deionized water until the pH value was about 7, then ultrasonically cleaned for 30 minutes, and dried at 103°C for 4 hours. Then the modified nutshell activated carbon is immersed in an equal volume of 0.4mol / L metal salt solution (the mole percentage of each metal active component is: 60% cobalt, 30% iron, 5% manganese, Nickel is 5%, and the total mole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com