Three-dimensional flexible metal negative electrode and preparation method thereof

A metal anode, three-dimensional flexible technology, applied in electrode manufacturing, battery electrodes, electrode current collector coating, etc., can solve the problem of metal dendrite growth and lack of affinity from the root cause, and avoid unevenness. The existence of nuclei, good flexibility, and the effect of high Coulomb efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

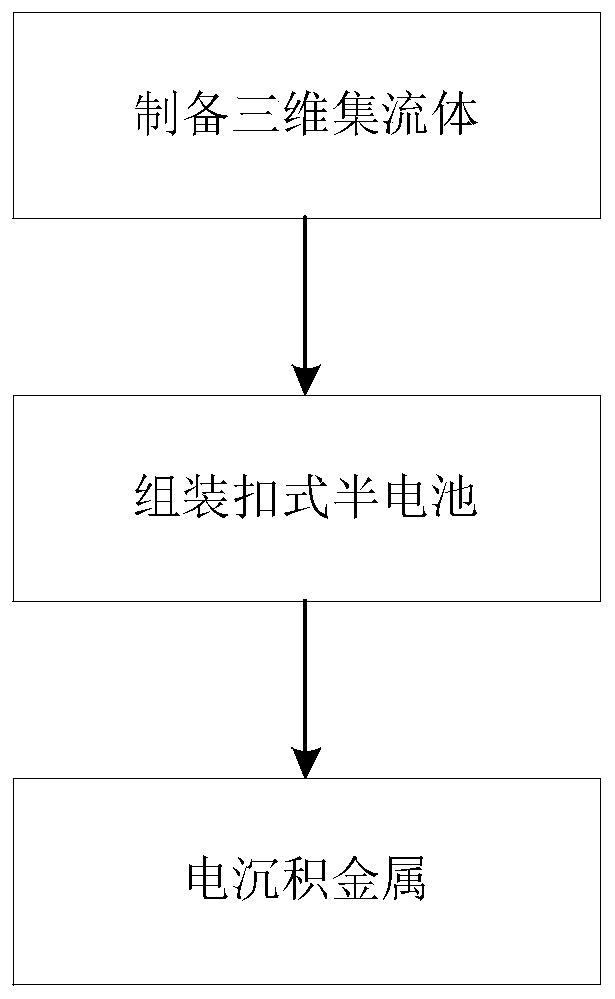

[0025] Such as figure 1 As shown, a method for preparing a three-dimensional flexible metal negative electrode, the main steps are as follows:

[0026] Step 1, first configure the metal nanowire ink, select a sponge of a certain size, then immerse the sponge in a certain volume of metal nanowire ink, squeeze it repeatedly for 10 seconds, take it out and place it in an oven for drying;

[0027] In step 2, the three-dimensional flexible current collector is used as the positive electrode, and the metal lithium, sodium or zinc is used as the negative electrode to assemble the button half-cell, and then the metal lithium, sodium or zinc is deposited by electrodeposition; wherein, when the metal is lithium or sodium, the Assemble the button half-cell under an inert atmosphere to avoid metal oxidation. When the metal is zinc, it can be in the air;

[0028] From top to bottom, the button battery includes a negative electrode shell, a metal negative electrode, a separator, a positive...

Embodiment 1

[0037] The concrete steps of preparation are:

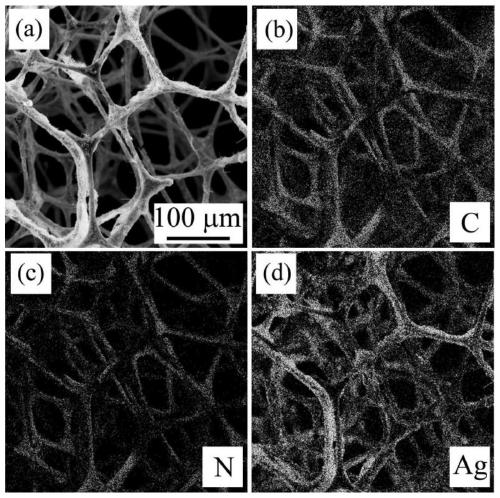

[0038] Step 1, first configure the silver nanowire ink with a concentration of 0.03mol / L, prepare a melamine sponge with a diameter of 8mm and a thickness of 0.8mm, then immerse the melamine sponge in 200μL of silver nanowire ink, squeeze it repeatedly for 10 seconds, and take it out Placed in an oven at 55°C for drying treatment, the obtained figure 2 The three-dimensional flexible current collector shown, from Figures (a) to (d), it can be seen that the silver nanowires are evenly attached to the melamine sponge skeleton, and the three-dimensional flexible current collector has a porous structure;

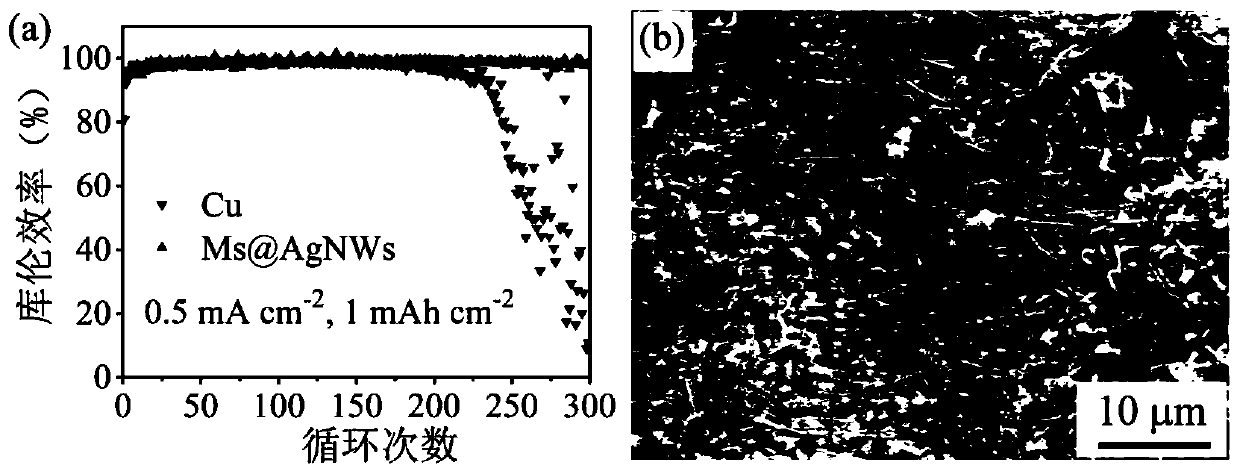

[0039] Step 2, the obtained three-dimensional flexible current collector or copper foil is used as the positive electrode, and lithium metal is used as the negative electrode. Under the condition of argon atmosphere, assemble a 2032 button half battery, and the electrolyte is 1mol / L lithium bistrifluoromethanesulfonylimide 1,3-dioxo...

Embodiment 2

[0042] The concrete steps of preparation are:

[0043] Step 1, first configure the silver nanowire ink with a concentration of 0.06mol / L, prepare a melamine sponge with a diameter of 9mm and a thickness of 1.4mm, then immerse the melamine sponge in 360μL of silver nanowire ink, squeeze it repeatedly for 10 seconds, and take it out Dry in an oven at 60°C. made as figure 1 The three-dimensional flexible current collector shown;

[0044] In step 2, the obtained three-dimensional flexible current collector or pure copper foil is used as the positive electrode, and sodium metal is used as the negative electrode. Under an argon atmosphere, assemble a 2032 button half-cell, and the electrolyte is 1mol / L sodium trifluoromethanesulfonate Diethylene glycol dimethyl ether solution. The obtained button cell was tested for its electrochemical performance with a blue electrochemical test system, and the test conditions were: the current density was 1mAcm -2 , with a circulating surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com