One-step method for synthesizing few-layer Nb2C material and application of few-layer Nb2C material

A one-step, two-step technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as cumbersome synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

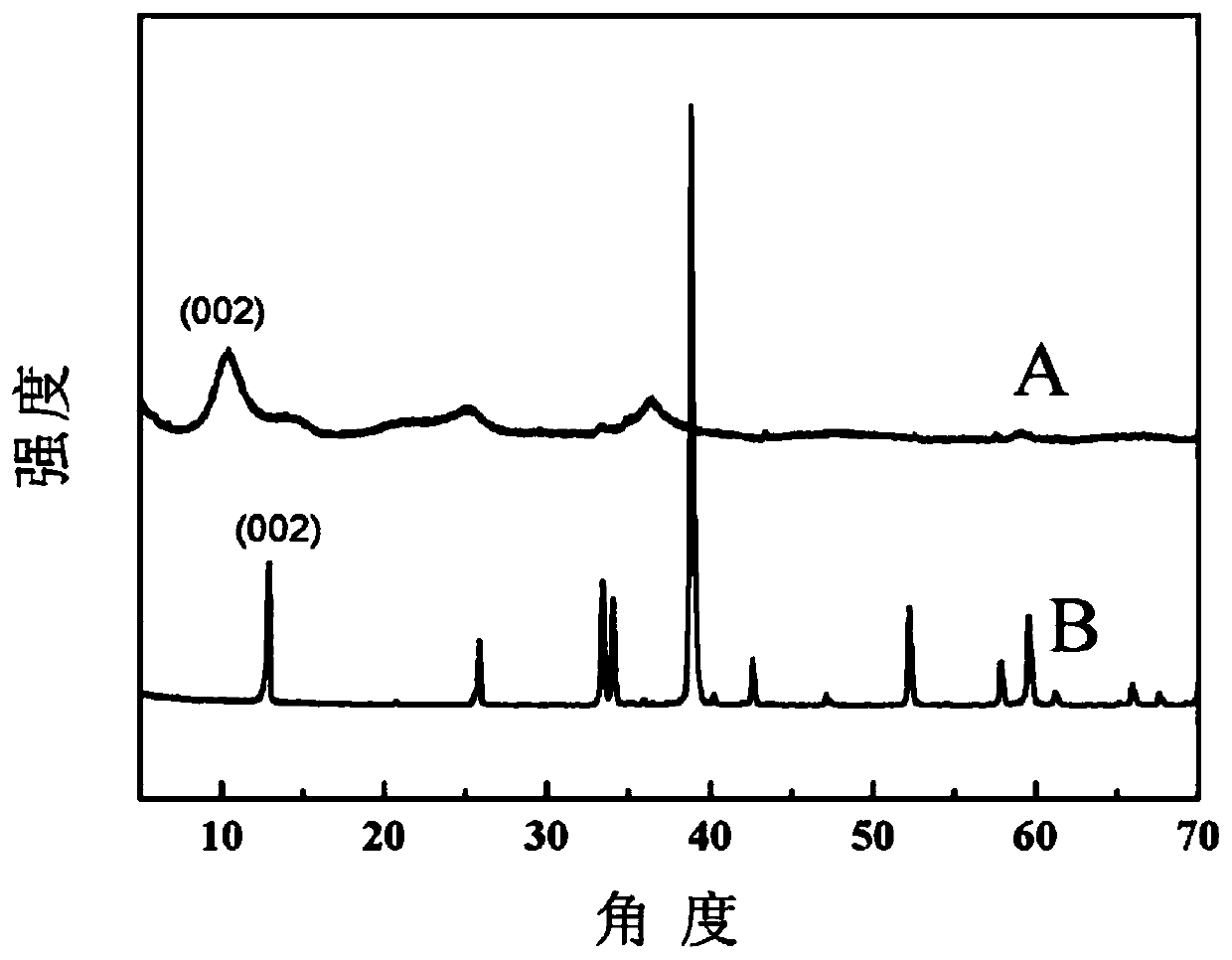

[0021] Specific implementation mode 1: In this implementation mode, few-layer Nb 2 The preparation method of C material is implemented according to the following steps:

[0022] 1. Add 0.5~1g Nb 2 Put the AlC powder into 30-60 mL of HF aqueous solution with a mass concentration of 30%-50%, and stir in a water bath at 55-65°C for 90-130 hours to obtain a reacted solution;

[0023] 2. Use a centrifuge to repeatedly centrifuge the solution after the reaction in step 1 at 8000-10000r / min. When the pH of the system reaches 5-6, reduce the speed of the centrifuge to 4000-6000r / min and continue to centrifuge. Ultrasonic treatment for 1-2 minutes before each centrifugation to make the solution more evenly dispersed, and the suspension was obtained after several times of centrifugation;

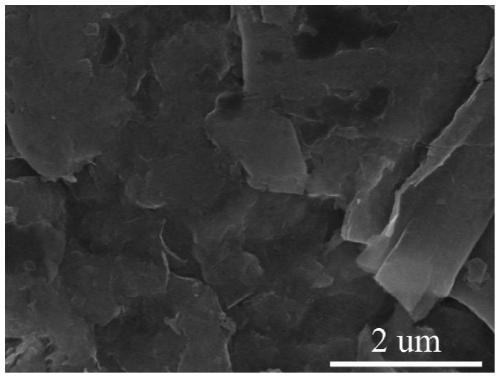

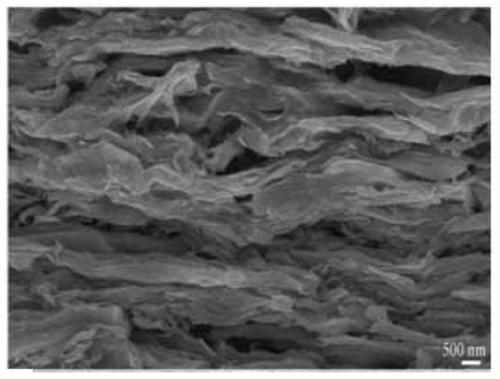

[0024] 3. Filtration of the suspension in step 2 to obtain a few layers of Nb 2 C film material.

[0025] Few-layer Nb prepared in existing 2 In the process of C material, it is generally by etch...

specific Embodiment approach 2

[0026] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 0.5-0.7gNb 2 Put the AlC powder into 30-40mL of HF aqueous solution.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step one, 0.5g Nb 2 AlC was put into 30 mL of 40% HF aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com