Method for preparing porous ceramic material for adsorbing heavy metals

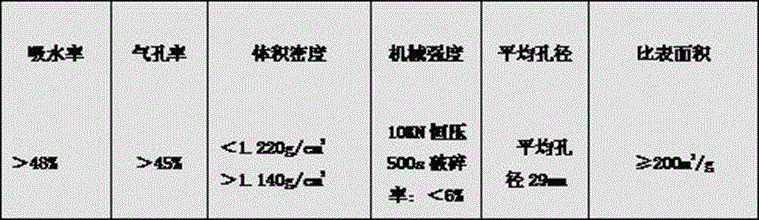

A technology for adsorbing heavy metals and porous ceramics, which is applied to ceramic products, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of high treatment costs and unsatisfactory treatment effects, and achieve high recycling rates, low production costs, and mechanical high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for preparing a porous ceramic material for adsorbing heavy metals, comprising the following steps:

[0017] 1) Preparation of mud: First, add 70kg of Anhui clay, 15kg of kaolin, 10kg of montmorillonite, 5kg of scallop powder, and 30kg of water into a mixer and mix for 20 minutes to prepare mud;

[0018] 2) Phosphorus compound solution preparation: Dissolve 20kg of monoammonium phosphate in 50kg of water to prepare monoammonium phosphate solution;

[0019] 3) Mixing: Put the monoammonium phosphate solution prepared in step 2) into the mud in step 1), and mix again with a mixer for 30 minutes;

[0020] 4) Forming the ceramic body: extruding the mud material prepared in step 3) into a green body;

[0021] 5) Drying of the ceramic green body: drying the green body prepared in step 4) at 200-220°C until the water weight percentage is lower than 0.8%;

[0022] 6) Firing the ceramic green body: the dried green body in step 5) can be fired at a firing temperature of...

Embodiment 2

[0024] A method for preparing a porous ceramic material for adsorbing heavy metals, comprising the following steps:

[0025] 1) Preparation of mud: First, add 55kg of Anhui clay, 30kg of kaolin, 10kg of montmorillonite, 5kg of safflower powder, and 35kg of water into a mixer and mix for 20 minutes to prepare mud;

[0026] 2) Phosphorus compound solution preparation: Dissolve 40kg of triammonium phosphate in 60kg of water to prepare a triammonium phosphate solution;

[0027] 3) Mixing: Put the triammonium phosphate solution prepared in step 2) into the mud in step 1), and mix again with a mixer for 30 minutes;

[0028] 4) Forming the ceramic body: extruding the mud material prepared in step 3) into a green body;

[0029] 5) Drying of the ceramic green body: drying the green body prepared in step 4) at 200-220°C until the water weight percentage is lower than 0.8%;

[0030] 6) Firing the ceramic green body: the dried green body in step 5) can be fired at a firing temperature o...

Embodiment 3

[0032] A method for preparing a porous ceramic material for adsorbing heavy metals, comprising the following steps:

[0033] 1) Preparation of mud: First, add 50kg of Anhui clay, 25kg of kaolin, 8kg of montmorillonite, 5kg of safflower powder, and 28kg of water into a mixer and mix for 20 minutes to prepare mud;

[0034] 2) Phosphorus compound solution preparation: Dissolve 30kg of monoammonium phosphate in 45kg of water to prepare monoammonium phosphate solution;

[0035] 3) Mixing: Put the monoammonium phosphate solution prepared in step 2) into the mud in step 1), and mix again with a mixer for 25 minutes;

[0036] 4) Forming the ceramic body: extruding the mud material prepared in step 3) into a green body;

[0037] 5) Drying of the ceramic green body: drying the green body prepared in step 4) at 200-220°C until the water weight percentage is lower than 0.8%;

[0038] 6) Firing the ceramic green body: the dried green body in step 5) can be fired at a firing temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com