Application of electrochemical oxygen sensor sensitive material

An oxygen sensor and sensitive material technology, applied in the field of electrochemical materials, can solve problems such as failure, false alarm, false alarm of oxygen sensor, etc., and achieve the effect of high specific area and suitable conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

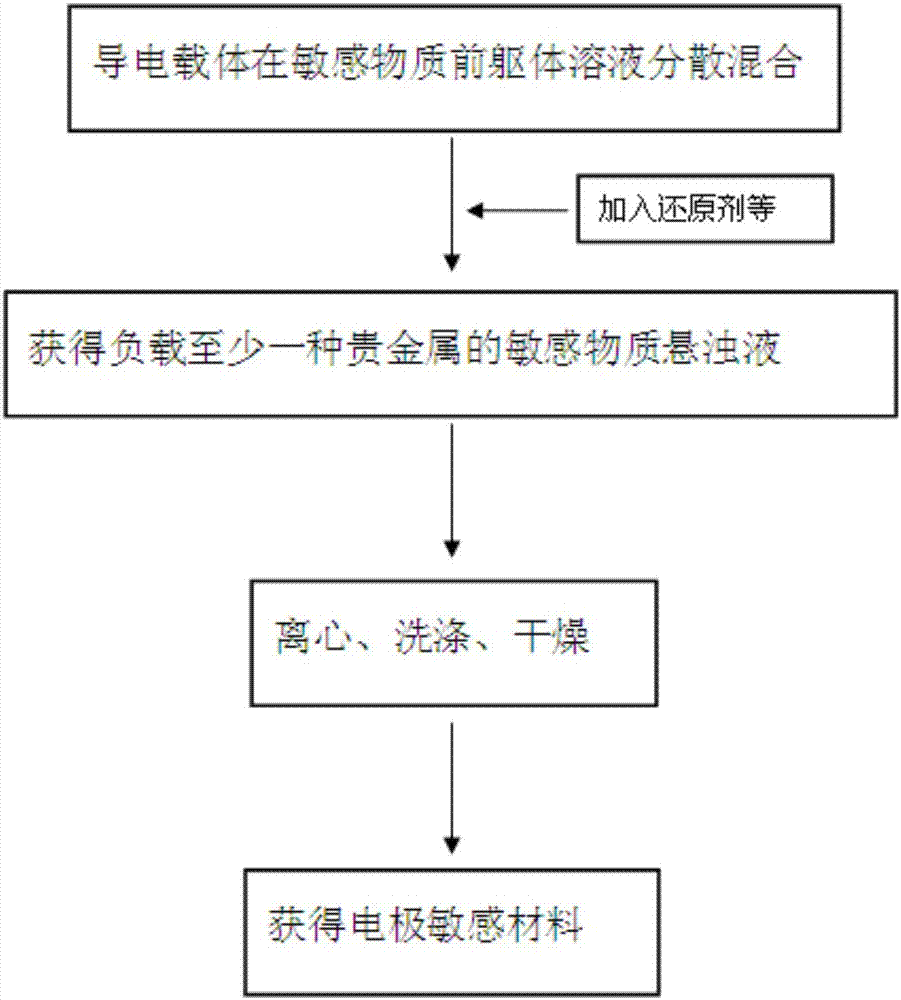

[0013] A preparation method for electrochemical oxygen sensor sensitive material, such as figure 1 shown, including the following steps,

[0014] Step 1. Take 250ml of noble metal precursor salt solution and 400mg of conductive carrier, disperse 400mg of conductive carrier into 250ml of noble metal precursor salt solution, keep stirring, and add 100mg of impregnation solution;

[0015] Step 2. Add 100 mg of impregnating solution to the mixed solution in step 1 under the condition of 15°C to 30°C. The concentration of the impregnating solution is 10 mg / m, and at the same time add alkaline solution to adjust the pH value of the solution to 10. ~11, obtaining the static solution of the loaded noble metal substance;

[0016] Step 3. Centrifuge the loaded noble metal substance static solution obtained in Step 2 at a speed of 4000rmp, wash with deionized water until the chlorine ion content is detected to be 0, and dry for 4 hours under vacuum conditions to obtain a dry powder , t...

Embodiment 1

[0027] Disperse 400mg of Cabot Corp Vulcan XC-72 activated carbon into 250mL of chloroplatinic acid, add 100mg of sodium borohydride under stirring, so that the concentration of sodium borohydride in deionized water is 10mg / mL. The temperature of the reaction system was controlled at room temperature. The pH value of the solution was adjusted to the range of 10-11 by ammonia water. Finally, the product was centrifuged, washed, and vacuum-dried for 4 hours to obtain the sensitive material. The average particle size is 20nm.

Embodiment 2

[0029] Disperse 400 mg of Cabot Corp Vulcan XC-72 activated carbon into 250 mL of ruthenium chloride solution, and add 100 mg of sodium borohydride under stirring to make the concentration of sodium borohydride in deionized water 10 mg / mL. The temperature of the reaction system was controlled at room temperature. The pH value of the solution was adjusted to the range of 10-11 by ammonia water. Finally, the product was centrifuged, washed, and vacuum-dried for 4 hours. The powder was evenly ground, placed on a watch glass, placed in a muffle furnace, and calcined at 300 degrees for 12 hours. That is, loaded ruthenium oxide is obtained. Grind and disperse the above materials to sensitive materials. Disperse into 250 mL of chloroplatinic acid, add 100 mg of sodium borohydride under stirring, so that the concentration of sodium borohydride in deionized water is 10 mg / mL. The temperature of the reaction system was controlled at room temperature. The pH value of the solution was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com