Tungsten carbide interface layer modified silicon carbide fiber-reinforced silicon carbide composite material and preparation method thereof

A silicon carbide fiber and composite material technology, applied in the field of aerospace material preparation, can solve the problems of limiting the use of SiC/SiC composite materials, corrosion of BN interface layer, crystal phase transformation, etc., and achieves excellent high temperature oxidation resistance, stable performance, The effect of high crystal phase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In a first aspect, the present invention provides a method for preparing a silicon carbide fiber-reinforced silicon carbide composite material modified by a tungsten carbide interface layer, the method comprising the following steps:

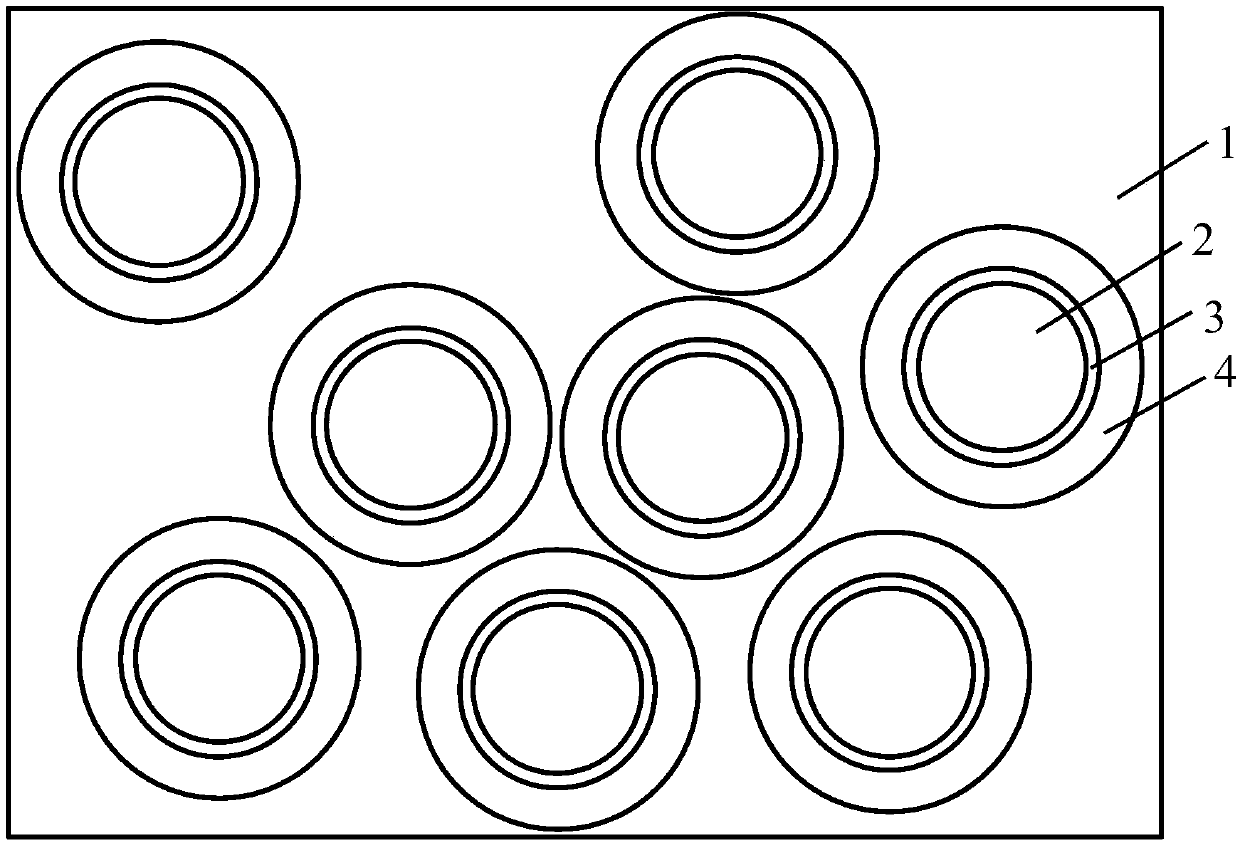

[0028] (1) A layer of tungsten carbide interface layer (WC interface layer) and a layer of silicon carbide interface layer (SiC interface layer) are sequentially deposited on the surface of silicon carbide fiber preform (SiC fiber preform) by chemical vapor deposition (CVD method). ), to obtain a modified silicon carbide fiber preform;

[0029] (2) impregnating the modified silicon carbide fiber preform obtained in step (1) with a carbon precursor solution (such as a resin precursor solution), and then curing and cracking the impregnated modified silicon carbide fiber preform in sequence A step of;

[0030] (3) Repeat step (2) at least once to make a porous silicon carbide fiber preform; and

[0031] (4) The porous silicon carbide fiber...

Embodiment 1

[0056] ① Weave the second-generation SiC fiber into a 2.5D silicon carbide fiber preform to obtain a silicon carbide fiber preform with a fiber volume fraction of 32%, with a warp density of 7 fibers / cm and a weft density of 3 fibers / cm; the silicon carbide fiber The preform is placed in a chemical vapor deposition furnace.

[0057] ②Using tungsten hexafluoride, methane, and hydrogen as the reaction precursors for depositing the tungsten carbide interface layer, under the vacuum conditions of deposition temperature of 700°C and deposition pressure of -0.04MPa, silicon carbide fibers were deposited by chemical vapor deposition. Deposit the fiber surface of the preform for 1 hour to obtain a tungsten carbide interface layer with a thickness of 500nm; then move the silicon carbide fiber preform deposited with the tungsten carbide interface layer to another chemical vapor deposition furnace, using trichloromethylsilane as the reaction precursor The body was deposited on the outsid...

Embodiment 2

[0063] ①Weave the second-generation SiC fiber into a 2.5D silicon carbide fiber preform to obtain a silicon carbide fiber preform with a fiber volume fraction of 39%, with a warp density of 8 fibers / cm and a weft density of 3.5 fibers / cm; the silicon carbide fiber The preform is placed in a chemical vapor deposition furnace.

[0064] ②Using tungsten tetrachloride, methane, and hydrogen as the reaction precursors for depositing the tungsten carbide interface layer, under the vacuum conditions of deposition temperature of 700°C and deposition pressure of -0.04MPa, silicon carbide fibers were deposited by chemical vapor deposition. Deposit the fiber surface of the preform for 1.5h to obtain a tungsten carbide interface layer with a thickness of 800nm; then move the silicon carbide fiber preform deposited with the tungsten carbide interface layer to another chemical vapor deposition furnace, and react with trichloromethylsilane The precursor was deposited on the outside of the tun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com