Composite converter magnesia-carbon brick and preparation method thereof

A converter magnesia-carbon brick and magnesia-carbon brick technology, which is applied in the field of refractory materials, can solve the problems of large difference in mud performance and strength, magnesia-carbon brick breakage, cracks, etc., and achieve improved oxidation resistance and slag erosion resistance , reduce destructive power, ensure the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention also discloses a preparation method of a composite converter magnesia-carbon brick, which comprises the following steps:

[0042] 1) Weigh fused magnesia particles, fused magnesia fine powder, carbonaceous raw materials, antioxidants, and binders according to the ratio of each raw material described in part A, mix them evenly, and discharge for later use;

[0043] 2) Weigh fused magnesia particles, fused magnesia fine powder, regenerated magnesia-carbon bricks, carbonaceous raw materials, and binder according to the ratio of each raw material described in part B, mix them evenly, and discharge for later use;

[0044] 3) Weigh the regenerated magnesia-carbon brick particles, regenerated magnesia-carbon brick powder, and binder according to the ratio of each raw material described in part C, mix them evenly, and discharge them for later use;

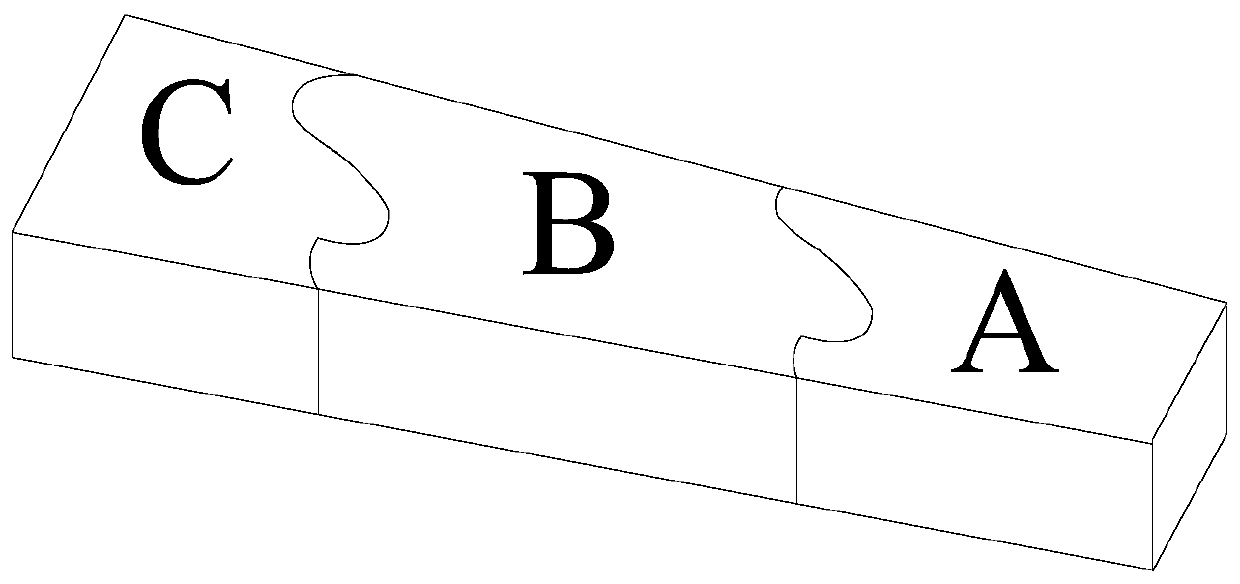

[0045] 4) Place baffles in the mold to divide the cavity of the mold into three parts, each part correspondingly pla...

Embodiment 1

[0049] This embodiment discloses a preparation method of a composite converter magnesia-carbon brick, which includes taking 50 parts of raw materials for part A, 40 parts of raw materials for part B, and 10 parts of raw materials for part C in stepwise molding, pressing and drying.

[0050] Wherein, the A part includes the following raw material components in parts by mass: fused magnesia particles: 65 parts, fused magnesia fine powder: 15 parts, graphite and carbon black composite powder: 13 parts, graphite modified Phenolic resin: 4 parts, metal aluminum powder and silicon powder: 3 parts; and 30 parts of magnesia with a particle size of 5-3 mm in the fused magnesia particles, 40 parts of magnesia with a particle size of 3-1 mm, and a particle size of 1-0.088 30 parts of magnesia in mm;

[0051] The B part includes the following raw material components in parts by mass: fused magnesia particles: 10 parts, fused magnesia fine powder: 20 parts, regenerated magnesia-carbon bric...

Embodiment 2

[0054] This embodiment discloses a preparation method of a composite converter magnesia-carbon brick, which includes taking 40 parts of raw materials for part A, 30 parts of raw materials for part B, and 30 parts of raw materials for part C, which are formed by step forming, pressing and drying.

[0055] Wherein, the A site includes the following raw material components in parts by mass: fused magnesia particles: 65 parts, fused magnesia fine powder: 15 parts, graphite and nano-carbon fiber composite powder: 13 parts, graphite modified Phenolic resin: 4 parts, metal aluminum powder and silicon powder: 3 parts; and 30 parts of magnesia with a particle size of 5-3 mm in the fused magnesia particles, 40 parts of magnesia with a particle size of 3-1 mm, and a particle size of 1-0.088 30 parts of magnesia in mm;

[0056] The B part includes the following raw material components in parts by mass: fused magnesia particles: 10 parts, fused magnesia fine powder: 20 parts, regenerated m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com