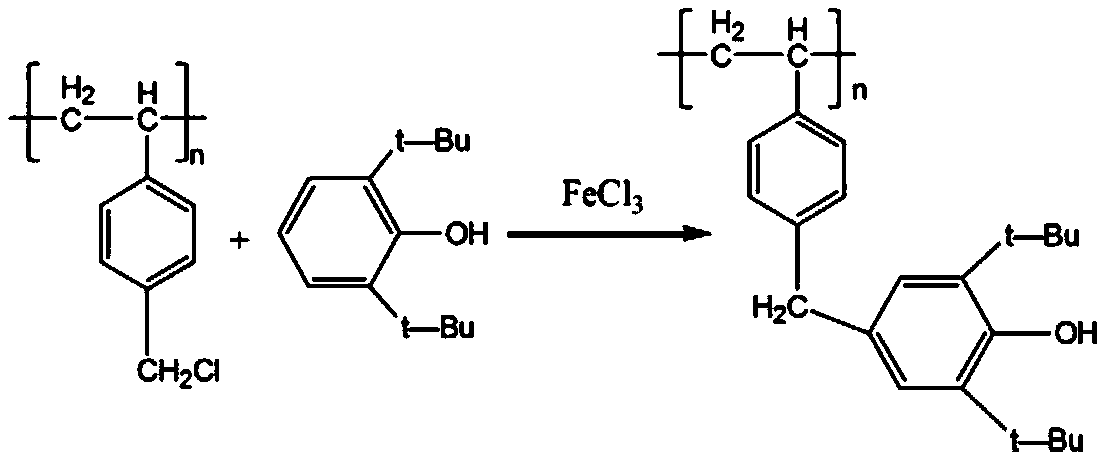

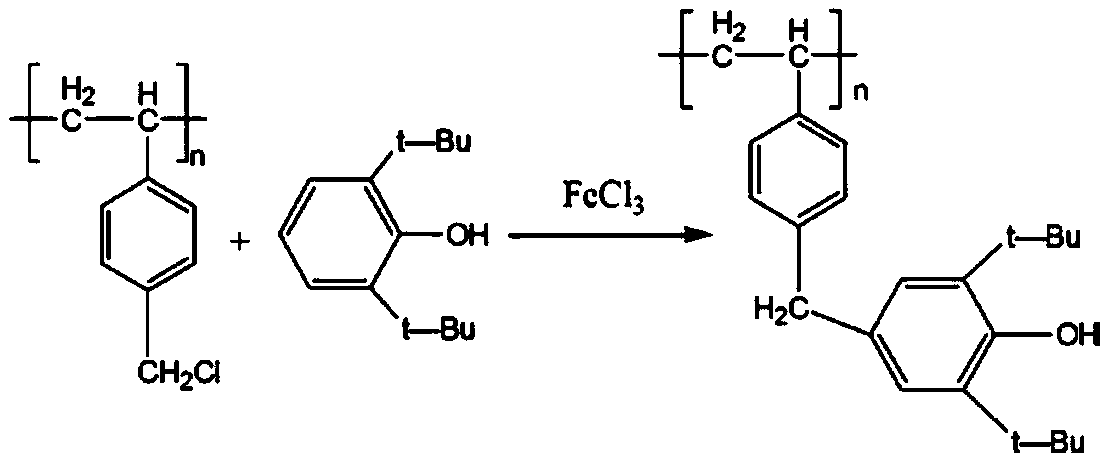

A kind of method and product thereof for preparing 2,6-di-tert-butylphenol antioxidant resin

A di-tert-butylphenol and anti-oxidation technology, which is applied in the synthesis of anti-oxidation resins, can solve the problems of liquid phase environmental pollution, difficult liquid phase separation, etc., and achieve the effect of stable anti-oxidation performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take the chlorine content as 17.75% and the specific surface area as 900m 2 g -1 45g (wet) of the cross-linked chloromethyl polystyrene resin was put into a 500mL three-necked reaction flask, and 360g of dichloroethane was added to swell for 24h. Add 15g of anhydrous ferric chloride and 25.5g of 2,6-di-tert-butylphenol, stir evenly, raise the temperature to 65°C, and react for 12h to obtain 2,6-di-tert-butylphenol-modified antioxidant polystyrene resin . Suction filtration, soak in 1M hydrochloric acid for 2 hours, wash with deionized water until neutral; then soak in 1M sodium hydroxide for 2 hours, wash with deionized water until neutral. Keep hydrated.

[0023] It is determined that the chlorine content of the 2,6-di-tert-butylphenol-modified anti-oxidation polystyrene resin in this embodiment is 1.31 wt%, and the water content is 45.37 wt%.

Embodiment 2

[0025] Take chlorine content as 16.80wt%, specific surface area as 890m 2 g -1 50g (wet) of the cross-linked chloromethyl polystyrene resin was put into a 500mL three-necked reaction flask, and 200g of dichloroethane was added to swell for 26h. Add 10.0g of anhydrous ferric chloride and 30.5g of 2,6-di-tert-butylphenol, stir evenly, raise the temperature to 60°C, and react for 14 hours to obtain 2,6-di-tert-butylphenol-modified antioxidant polystyrene resin. Suction filter, soak in 1M hydrochloric acid for 1 hour, wash with deionized water until neutral; then soak in 1M sodium hydroxide for 1 hour, wash with deionized water until neutral. Keep hydrated.

[0026] It is determined that the chlorine content of the antioxidant resin supported by 2,6-di-tert-butylphenol in this embodiment is 1.25 wt%, and the water content is 45.38 wt%.

Embodiment 3

[0028] The chlorine content is 17.15%, and the specific surface area is 810m 2 g -1 50.0 g (wet) of the cross-linked chloromethyl polystyrene resin was put into a 500 mL three-necked reaction flask, and 300 g of dichloroethane was added to swell for 12 hours. Add 20.0 g of anhydrous ferric chloride and 34.5 g of 2,6-di-tert-butylphenol, stir evenly, raise the temperature to 70°C, and react for 16 hours to obtain 2,6-di-tert-butylphenol-modified antioxidant polystyrene resin. Suction filtration, soak in 1M hydrochloric acid for 1.5h, wash with deionized water until neutral; then soak in 1M sodium hydroxide for 1.5h, wash with deionized water until neutral. Keep hydrated.

[0029] It has been determined that the chlorine content of the 2,6-di-tert-butylphenol-modified anti-oxidation polystyrene resin in this embodiment is 1.12 wt%, and the water content is 47.61 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com