Functional OBC (olefin block copolymer) antioxidant masterbatch as well as preparation method thereof

An olefin block and anti-oxidation masterbatch technology, which is applied in the field of functionalized olefin block copolymer anti-oxidation masterbatch and its preparation, can solve problems such as difficult to improve inherent properties, low melting point of POE, discounted anti-oxidation effect, etc. To achieve the effect of ensuring thermal oxygen stability, stable anti-oxidation performance, and stable anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

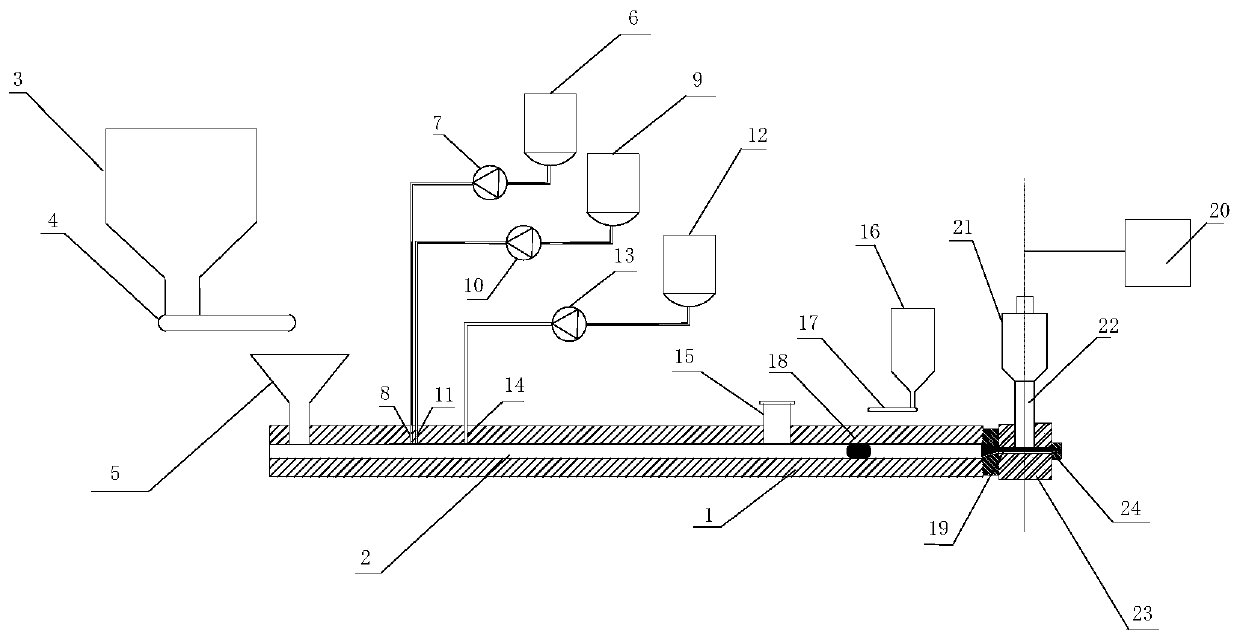

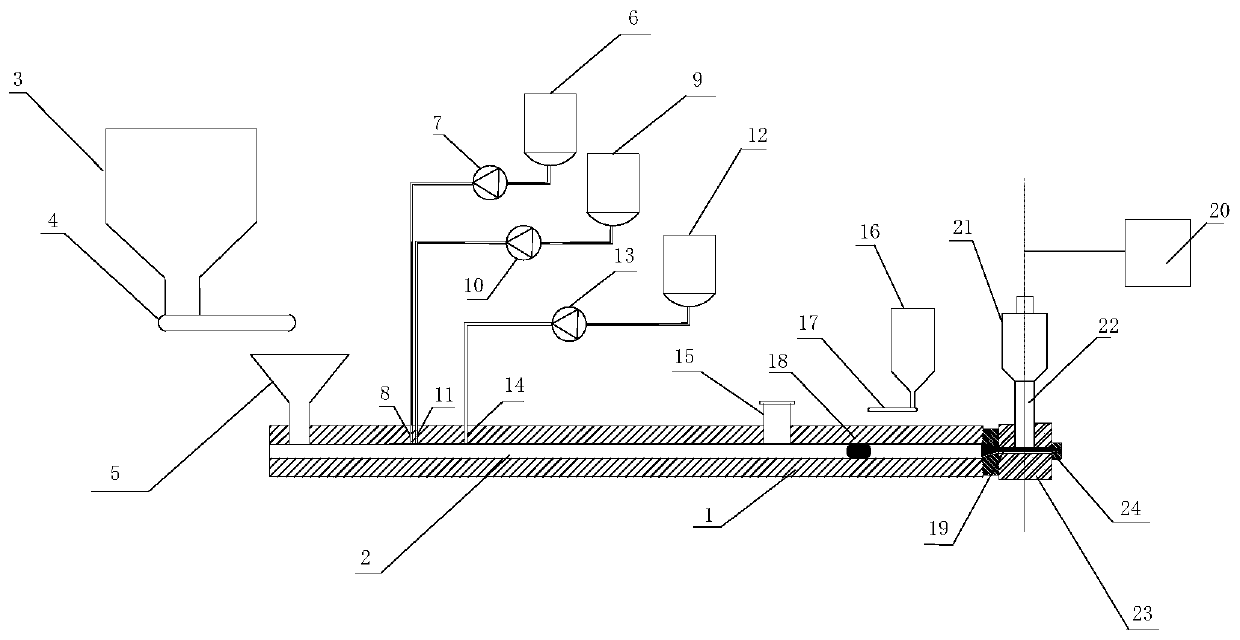

Method used

Image

Examples

Embodiment 1

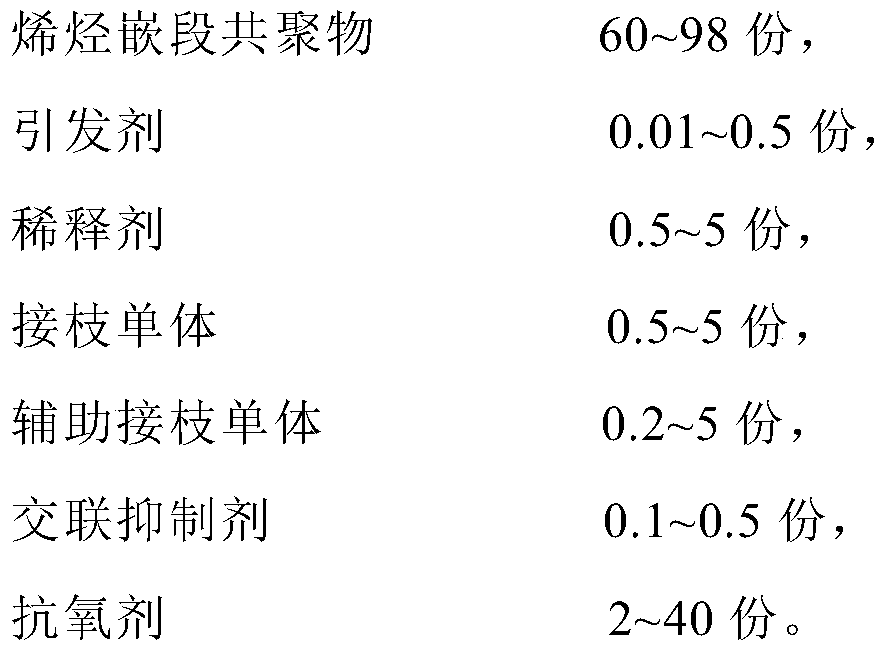

[0036] First, 95 parts of olefin block copolymer INFUSE TM 9007 (Dow company, MI: 0.5g / 10min, density: 0.866g / cm -3) and 0.5 part of triphenyl phosphite mix uniformly and join in the extruder from the main feeding port by the weight loss metering system; 2 parts of maleic anhydride are dissolved in 3 parts of diluent butanone as graft monomer, Added into the extruder through the first liquid feeding system, 1 part of α-methylstyrene was added into the extruder through the second liquid feeding system as an auxiliary grafting monomer, 0.2 part of dicumyl peroxide Dissolve in 1 part of methyl ethyl ketone, add to the extruder through the third liquid feeding system, add a mixture of 2.5 parts of hindered phenolic antioxidant 1098 and 2.5 parts of phosphite antioxidant 168 from the side feeding port , when the melt passes through the die, it is ultrasonically extruded to obtain a sample.

[0037] In this scheme, the aspect ratio of the twin-screw extruder is 52, and the tempera...

Embodiment 2

[0039] 30 parts of olefin block copolymer INFUSE TM 9100 (Dow company, MI: 1g / 10min, density: 0.877g / cm -3 ) and 30 copies of INFUSE TM 9530 (Dow company, MI: 5g / 10min, density: 0.887g / cm -3 ) and 0.1 part of caprolactam are mixed uniformly and then added into the extruder from the main feeding port by a weight loss metering system; 1 part of acrylic acid is dissolved in 0.5 part of diluent acetone as a graft monomer, and passed through the first liquid feeding system Join in the extruder, 1.5 parts of divinylbenzene are joined in the extruder by the second liquid feeding system as auxiliary grafting monomer, 0.3 part of tert-butyl peroxydicarbonate is dissolved in 1 part of acetone, Join in the extruder by the 3rd liquid feeding system, add the mixture of 25 parts of thioether antioxidant dilauryl thiodipropionate and 15 parts of hindered phenolic antioxidant 1076 from side feeding port, melt The samples were obtained by extruding the body through the die after ultrasonica...

Embodiment 3

[0042] 80 parts of olefin block copolymer INFUSE TM 9500 (Dow company, MI: 5g / 10min, density: 0.877g / cm -3 ) and 0.3 part of stearic acid amide are mixed and joined in the extruder by the weight loss metering system from the main feeding port; Added into the extruder through the first liquid feeding system, 5 parts of styrene were added into the extruder through the second liquid feeding system as an auxiliary grafting monomer, 0.05 parts of 2,5-dimethyl-2, 5-bis(tert-butylperoxy)hexane was dissolved in 1 part of ethanol, added to the extruder through the third liquid feeding system, and 20 parts of amine antioxidant N-cyclohexyl was added from the side feeding port -N'-Phenyl-p-phenylenediamine, when the melt passes through the die, it is ultrasonically extruded to obtain a sample.

[0043] In this scheme, the aspect ratio of the extruder is 48, and the temperature of each zone is set between 80 and 180°C. The screw speed is 400rpm, the ultrasonic power is controlled at 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com