Fuzzing roller rolled by carbon fiber composite material in two-step method

A composite material and carbon fiber technology, used in textiles and papermaking, roughening, fabric surface trimming, etc., can solve the problems of poor fatigue resistance of steel raising rollers, serious energy loss, and heavy raising rollers, and save equipment. The effect of maintenance cost, equipment energy consumption reduction and equipment speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

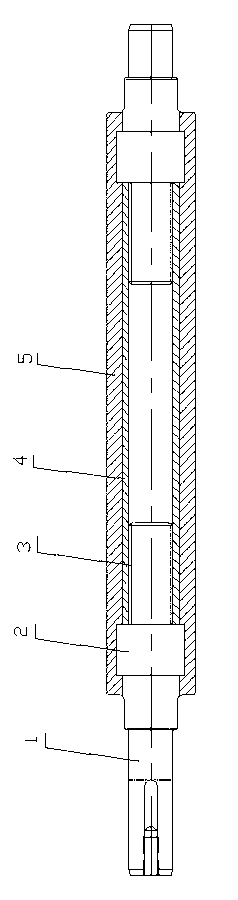

[0012] A two-step carbon fiber composite material rolling raising roller comprises a roller body of the raising roller and shaft heads arranged at both ends of the roller body.

[0013] (1) First of all, carry out the first lay-up design, first wind the carbon fiber prepreg on the designed mold mandrel, after reaching the required thickness of the lay-up, then put it into the curing box for curing, and demould after cooling. Into a carbon fiber liner for spare.

[0014] (2) The shaft head includes the front part of the shaft head and the bonding section plugged into the carbon fiber liner, a reinforced shoulder is arranged between the front part of the shaft head and the bonding section, and the outer surface of the bonding section Grooves for easy bonding are processed, and the bonding section is coated with adhesive and then inserted into the carbon fiber inner tube for bonding, and the reinforced shoulder is blocked at the end of the carbon fiber inner tube. The groove on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com