Structure and method for improving tribological performance of E690 steel

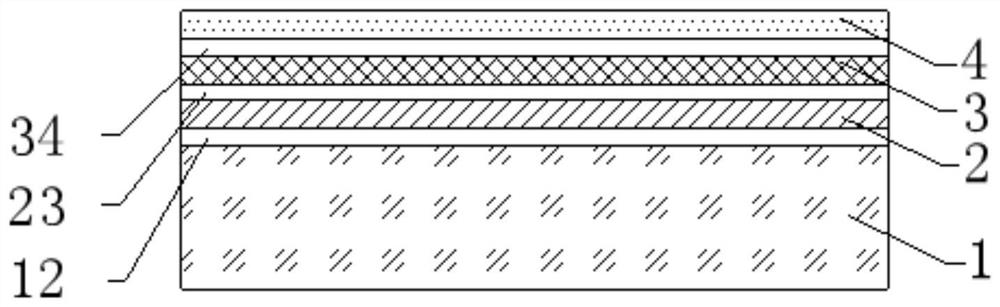

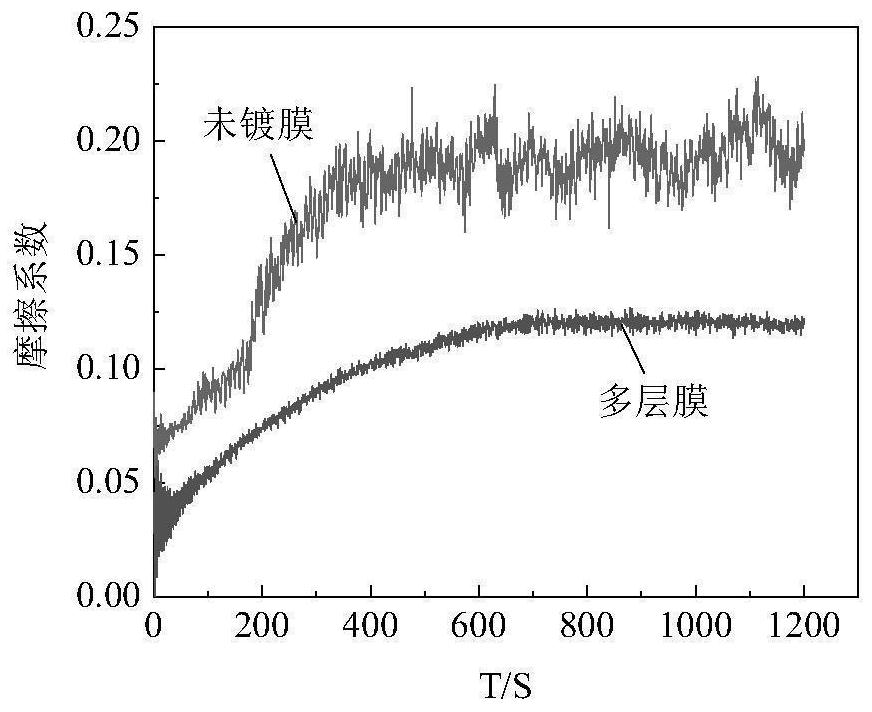

A tribology and performance technology, applied in the field of surface modification, which can solve the problems of low hardness, component failure, matrix corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

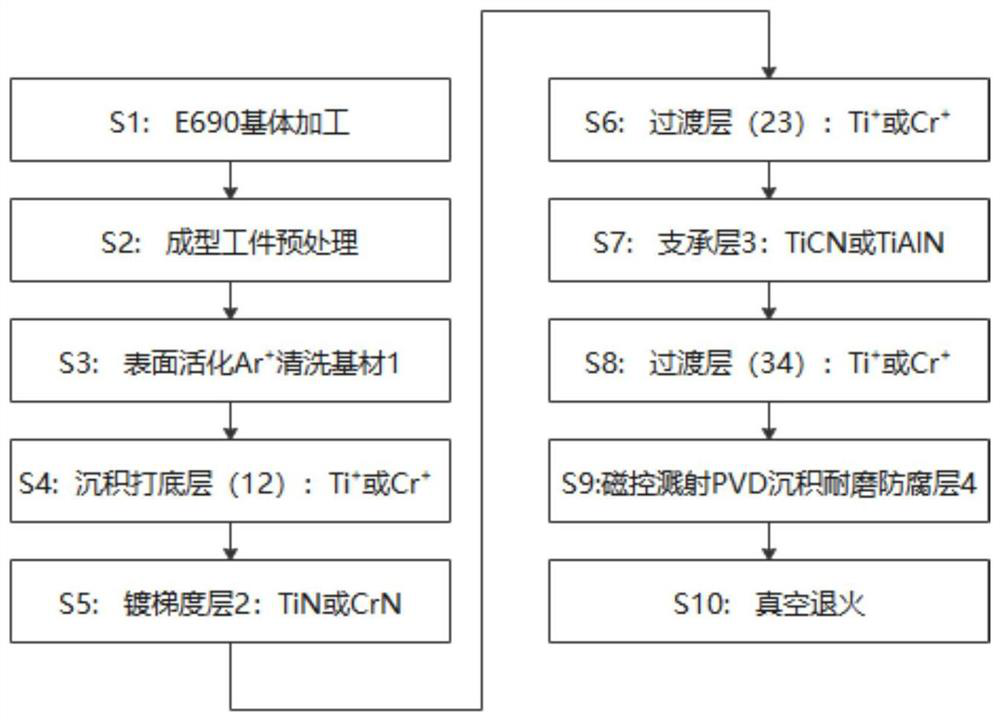

[0046] The film structure is Ti / TiN / TiCN / TiCrAlN set from the inside and the outside, the total deposition thickness is 2.5um, Ti layer: open the Ti target, control the working pressure 0.5Pa, pulse bias 300V, duty cycle 20%, arc Current 100A; TiN layer: control the total working pressure 0.8Pa, Ti target current 120A, N 2 Flow rate 30sccm; TiCN layer: open Ti target, arc current 110A, control N 2 The flow is 80sccm, C 2 H 2 The flow rate is 100sccm; TiCrAlN layer: 3 targets co-sputtering: Ti target, Al target use DC power supply, Cr target use RF power supply, background vacuum 5.0×10 -4 Pa, the working pressure is about 0.9Pa, the partial pressure of argon and nitrogen are both 0.4Pa and 0.5Pa, the negative bias voltage of the substrate is 100V, the substrate temperature is 300℃, the Ar pressure in the furnace is kept at 0.05Mpa during annealing, and the temperature rises during annealing. The speed is 15°C / min, the temperature is kept for 2h, and it is cooled with the fu...

Embodiment 2

[0050] The film structure is Cr / CrN / TiAlN / TiCrAlN set from the inside and the outside, the total deposition thickness is 3.0um, Cr layer: open the Cr target, control the working pressure 0.5Pa, pulse bias 300V, duty cycle 20%, arc Current 100A; CrN layer: control the total working pressure 0.8Pa, Cr target current 100A, N 2 Flow rate 25sccm; TiAlN layer: open Ti target, Al target, arc current 80A, control N 2 The flow rate is 30sccm, TiCrAlN layer: 3 targets co-sputtering: Ti target, Al target use DC power supply, Cr target use RF power supply, background vacuum 5.0×10 -4 Pa, the working pressure is about 0.9Pa, the partial pressure of argon and nitrogen are both 0.4Pa and 0.5Pa, the negative bias voltage of the substrate is 100V, and the substrate temperature is 300°C; during annealing, the Ar pressure in the furnace is kept at 0.05Mpa, and the annealing temperature is increased. The speed is 15°C / min, the temperature is kept for 2h, and it is cooled with the furnace.

[00...

Embodiment 3

[0055] The film structure is Ti / TiN / TiAlN / TiCrAlN set from the inside and the outside, the total deposition thickness is 3.0um, Ti layer: open the Ti target, control the working pressure 0.5Pa, pulse bias 300V, duty cycle 20%, arc Current 110A; TiN layer: control the total working pressure 0.8Pa, TI target current 100A, N 2 Flow rate 25sccm; TiAlN layer: open Ti target, Al target, arc current 80A, control N 2 The flow rate is 30sccm; TiCrAlN layer: 3 targets co-sputtering, Ti target, Al target use DC power supply, Cr target use RF power supply, background vacuum 6.0×10 -4 Pa, the working pressure is about 0.7Pa, the partial pressure of argon and nitrogen are both 0.3Pa and 0.4Pa, the negative bias voltage of the substrate is 150V, the substrate temperature is 200℃, the Ar pressure in the furnace is maintained at 0.04Mpa during annealing, and the temperature rises during annealing. The speed is 15°C / min, the temperature is kept for 4h, and the furnace is cooled.

[0056] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com