Manufacture method of waterproof power connector and waterproof connector adopting same

A manufacturing method and technology of power connectors, which are applied to the assembly/disassembly of contact parts, the connection and connection through deformation, and the device for reducing the stress at the connection of wires, etc., which can solve the problems of high production cost, manual glue fixing, and product yield. Low-level problems, to achieve the effect of improving waterproof performance, preventing deformation, and enhancing tensile capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

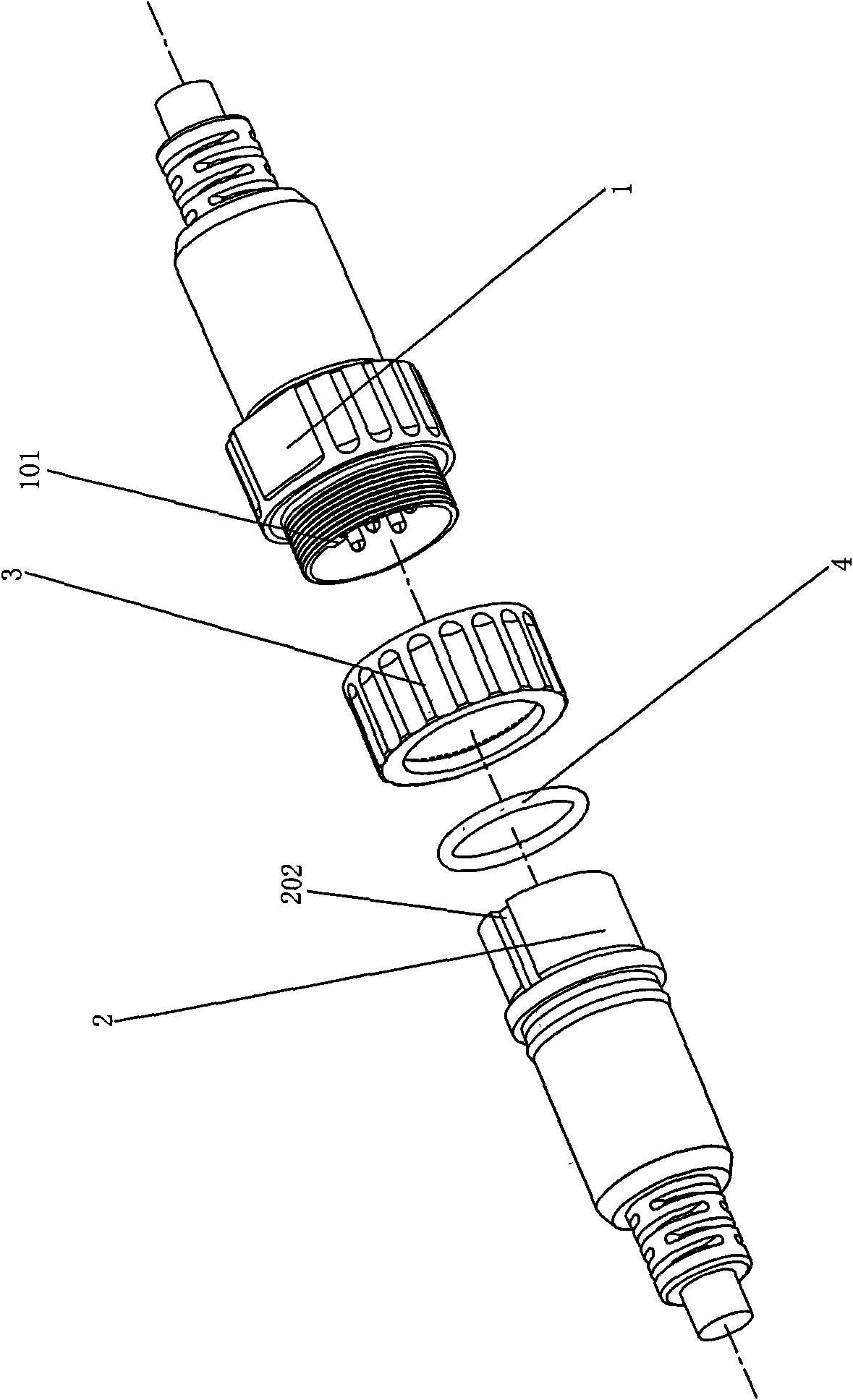

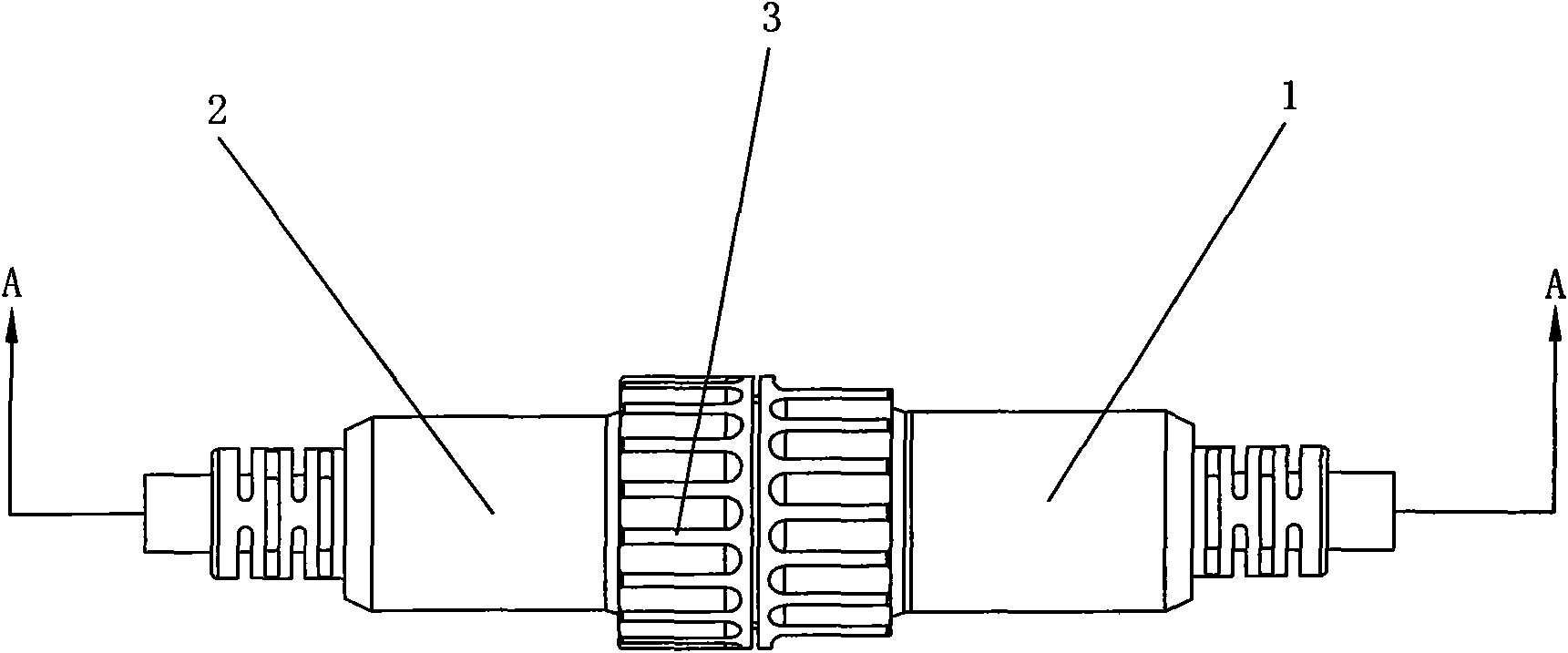

[0029] In order to further introduce the present invention in detail, the present invention will be described in detail below in conjunction with the accompanying drawings.

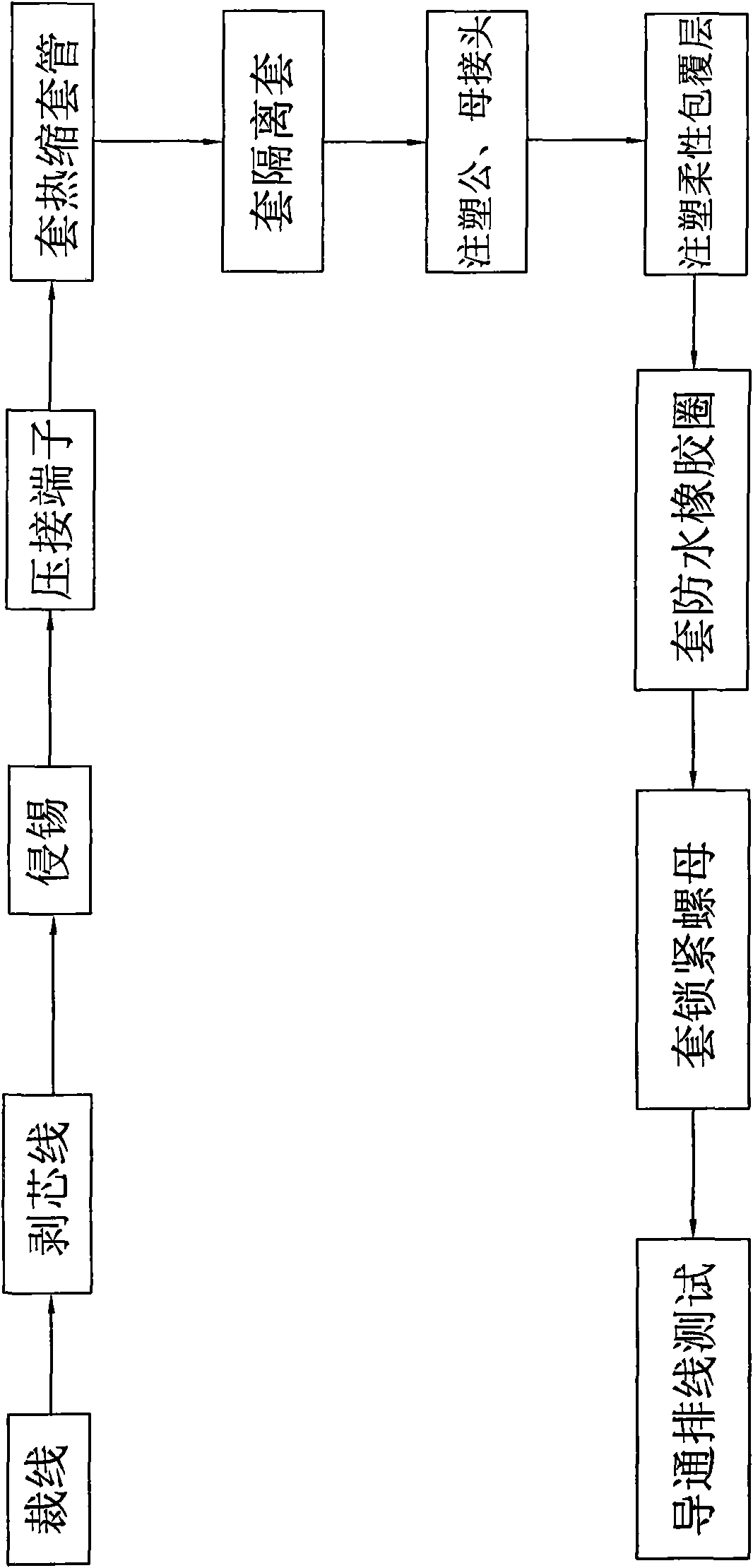

[0030] The invention provides a method for making a waterproof power connector, such as figure 1 Shown: The method includes the following steps:

[0031] a) First cut the power cords 21, 22 of required length, such as Figure 4 shown.

[0032] b) Next, the core wire sheaths at one end of the power cords 21, 22 are peeled off so that the metal wires 13, 23 leak out, and the metal wires 13, 23 are put into tin trays for immersion tin processing, so that in the subsequent steps Easy electrical connection.

[0033] c) Then put the metal wires 13 and 23 into the terminal machine to crimp the metal male terminal 7 and the metal female terminal 5 respectively, and make a heat-shrinkable sleeve 81 at the joint between the metal male terminal 7 and the metal wire 13, A heat-shrinkable sleeve 82 is sheathed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com