Electric tower high-strength steel special for extra-high voltage

A technology of UHV and high-strength steel, which is applied in the field of high-strength steel for UHV electric towers, can solve the problems of waste of resources, heavy installation workload, and increased project investment, and achieve not easy fracture and plastic deformation, high strength and toughness, The effect of high strength and toughness

Active Publication Date: 2016-02-03

STATE GRID CORP OF CHINA +1

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the steel towers of high-voltage transmission lines in my country generally use Q235 and Q345 structural steels of two strength grades. Compared with developed countries, there are fewer varieties and lower strength. With the development of UHV transmission lines, iron towers tend to be larger and towers The design load is also increasing. The strength and specifications of Q235 and Q345 steel are difficult to meet the use requirements of large-load towers. When the design load of the components is large, the method of combining sections is generally used to meet the bearing capacity requirements of the tower components. This will inevitably lead to an increase in the number and specifications of iron tower rods, complex node structures, and heavy installation workload, which not only increases project investment, but also wastes a lot of resources

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

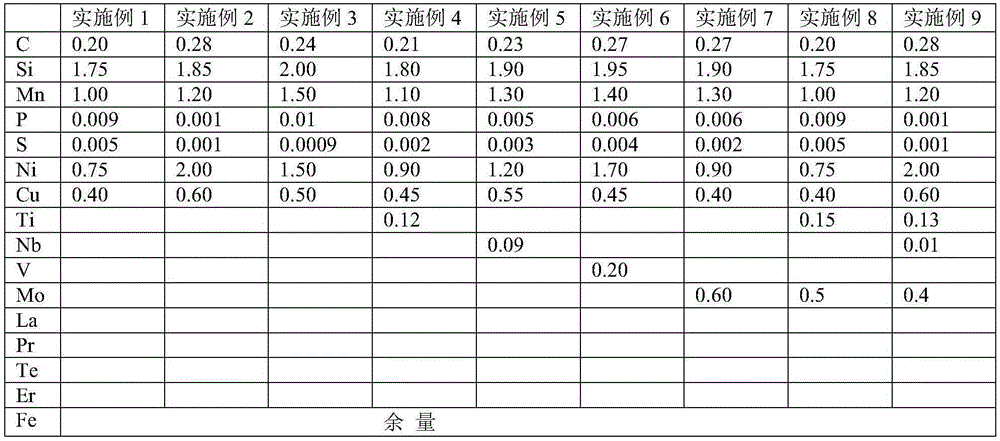

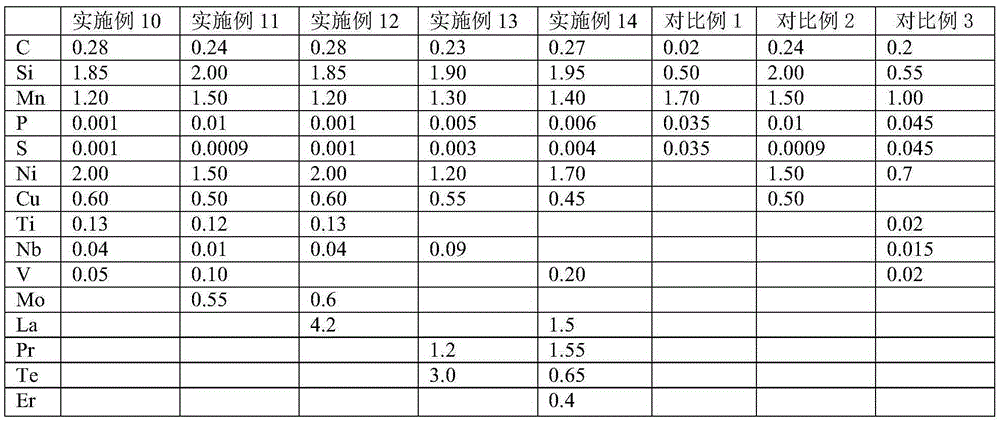

Embodiment 1~14

[0038] Examples 1-14, see Table 1 for the specific composition of the high-strength steel used for UHV line towers, and see Table 2 for the specific process parameters.

[0039] Comparative Example 1 and Comparative Example 3 are based on the composition of steel in the prior art, and their specific process parameters are shown in Table 2;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of steel production, and particularly relates to an electric tower high-strength steel special for extra-high voltage. The electric tower high-strength steel special for extra-high voltage comprises, by weight, 0.20-0.28% of carbon, 1.75-2.0% of silicon, 1.0-1.5% of manganese, smaller than or equal to 0.01% of phosphorus, smaller than or equal to 0.005% of sulfur, 0.75-2.0% of nickel, 0.4-0.6% of copper and the balance iron and inevitable impurities. A manufacturing method for the high-strength steel for an extra-high voltage line tower includes the steps of raw material treatment, smelting, refining, die casting, forging, cooling and tempering. The high-strength steel manufactured through the manufacturing method is high in strength, long in service life and high in corrosion resistance, oxidation resistance and high temperature resistance, the manufacturing method is simple, and production cost is low.

Description

technical field [0001] The invention belongs to the field of steel production, and in particular relates to high-strength steel for special high-voltage electric towers. Background technique [0002] In recent years, with the rapid development of my country's economy, the demand for electricity in various regions has continued to increase, making my country's power grid construction have unprecedented development. With the need for long-distance and large-capacity power transmission, the voltage level has been continuously upgraded, with 1000kV AC and 800kV The DC UHV line is under construction as the backbone network frame; the transmission tower has also developed from the early wooden pole concrete pole to the steel structure tower commonly used now, and is developing in the direction of large-scale, steel structure, and scale. The amount of steel used in transmission towers continues to increase, the bearing capacity of a single component required is getting higher and hig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/16C21D8/00

Inventor 张利李秀珍张庆军苏征

Owner STATE GRID CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com