Valve forming mould covered with wear-resistant heat insulation film layer and manufacturing method of valve forming mould

A technology for forming molds and heat insulation films, which is applied in the direction of plating, coating, sputtering plating, etc. of superimposed layers. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

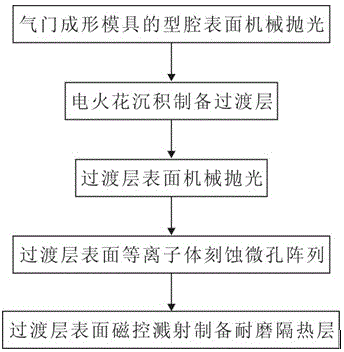

[0026] see figure 1 , the embodiment of the preparation method of the valve forming mold covered with wear-resistant and heat-insulating film layer of the present invention comprises the following steps:

[0027] ①. Mechanically polish the cavity surface of the valve forming mold covered with wear-resistant and heat-insulating film;

[0028] ②. The transition layer is prepared by EDM;

[0029] ③, the surface of the transition layer is mechanically polished;

[0030] ④, Plasma etching microhole array on the surface of the transition layer;

[0031] ⑤. The wear-resistant and heat-insulating layer is prepared by magnetron sputtering on the surface of the transition layer.

Embodiment 1

[0033] Mold cavity material: 3Cr2W8V.

[0034] Electrospark deposition preparation transition layer (NiCoCrAlY) process parameters: output voltage 100 V, capacitance 150 μF, frequency 2500 Hz, specific deposition time 1.0 min / cm 2 , The electrode speed is 2500r / min.

[0035] The process parameters of plasma etching microhole array: the degree of vacuum is 1.0Pa, the substrate negative bias is 650V, and the time is 10min.

[0036] Magnetron sputtering to prepare wear-resistant heat insulation layer (ZrO2) process parameters: working pressure 0.1 Pa, loading negative bias voltage -100 V, sputtering voltage 500 V, target sputtering current density 0.1 A / cm 2 , and the sputtering time was 0.5 hours.

Embodiment 2

[0038] Mold cavity material: 4Cr5MoSiV1.

[0039] Electrospark deposition preparation transition layer (NiCoCrAlY) process parameters: output voltage 150V, capacitance 100μF, frequency 3000Hz, specific deposition time 1.2min / cm 2 , The electrode speed is 3000r / min.

[0040] The process parameters of plasma etching microhole array: the degree of vacuum is 1.2Pa, the substrate negative bias is 700V, and the time is 15min.

[0041] Magnetron sputtering preparation of wear-resistant heat insulation layer (ZrO2) process parameters: working pressure 0.1 Pa, sample loading negative bias -300 V, sputtering voltage 600 V, target sputtering current density 0.12 A / cm2, sputtering time for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com