Heavy type commercial vehicle V-shaped thrust rod assembly and assembly method thereof

A thrust rod, commercial vehicle technology, used in vehicle parts, transportation and packaging, cantilevers mounted on pivots, etc., can solve problems such as accelerated wear, failure of V-type thrust rods, poor sealing, etc. The effect of life requirements, strong axial bearing capacity and large structural compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings, the technical solutions in the present invention are clearly and completely described. The described embodiments are only a part of the present invention. All other inventions and creations obtained belong to the protection scope of the present invention.

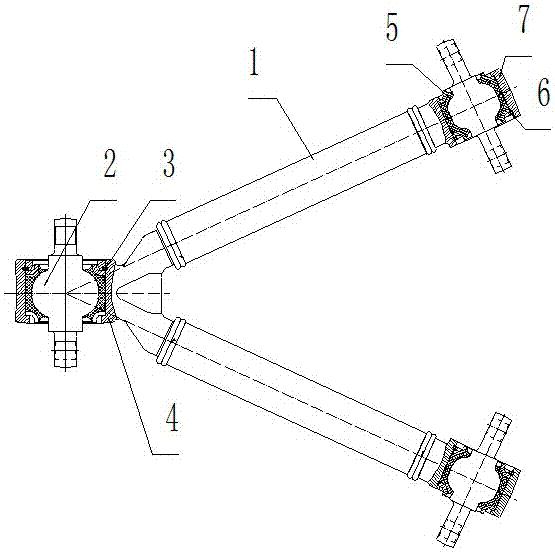

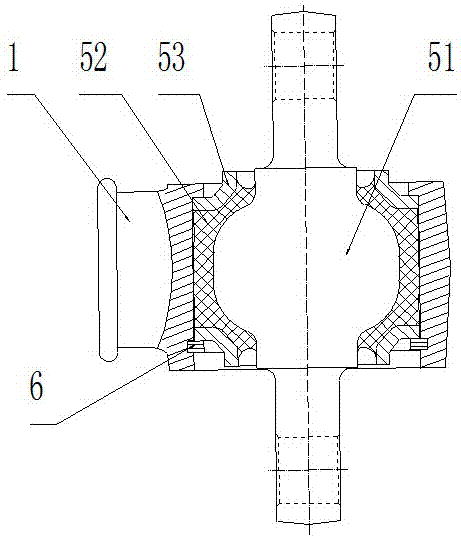

[0021] Such as figure 1 — Figure 7 As shown, a V-shaped thrust rod assembly for a heavy-duty commercial vehicle in this embodiment includes a V-shaped end assembly, a small end assembly and a connecting rod 1, and the V-shaped end assembly and the small end assembly of this embodiment Both are connected together with the connecting rod 1 by friction welding.

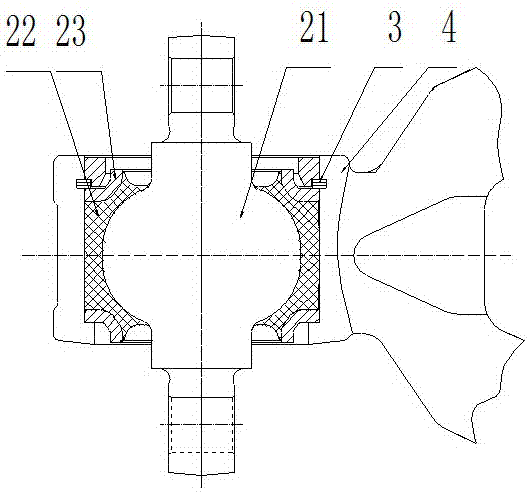

[0022] Depend on figure 1 , figure 2It can be seen that the V-shaped end assembly of this embodiment includes a V-end reinforced ball joint 2 , a V-end retaining ring 3 and a V-shaped end 4 . The V-end reinforced ball joint 2 is installed in the V-shaped end head 4, and is composed of a V-end intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com