Thermo-magnetic protection device and electric protection device of thermo-magnetic protection device

A protection device, thermo-magnetic technology, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of inability to repeat adjustment, plastic deformation, affecting production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

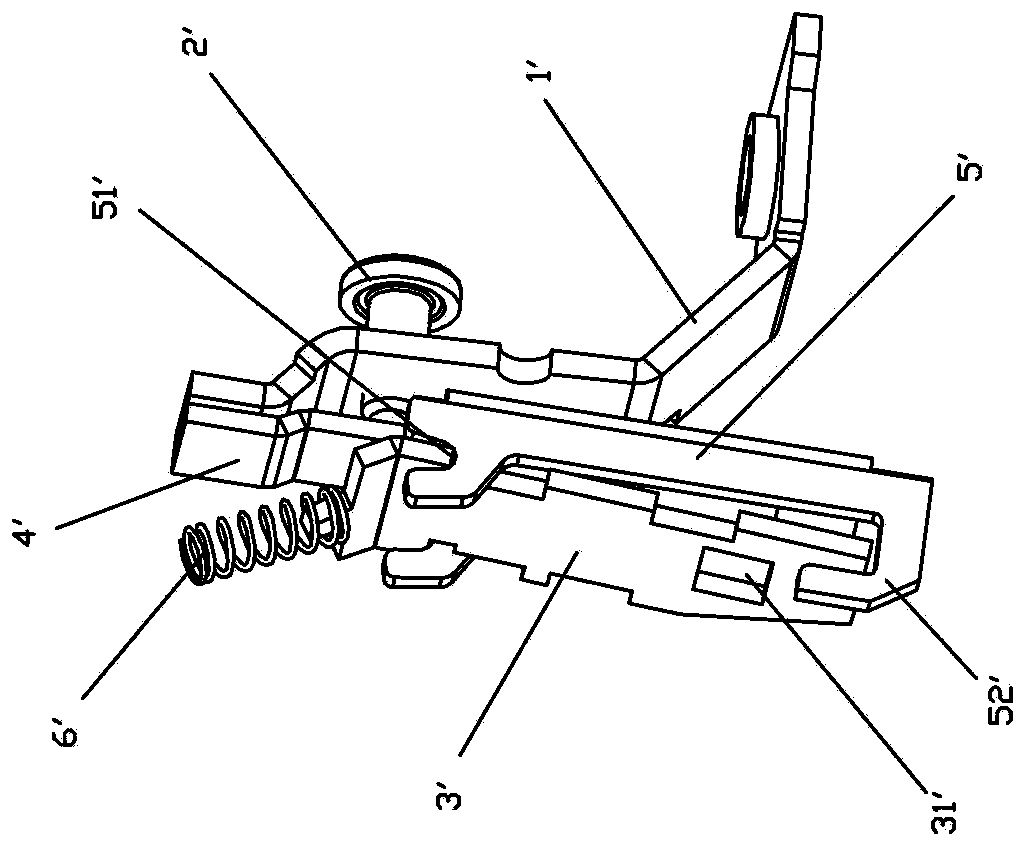

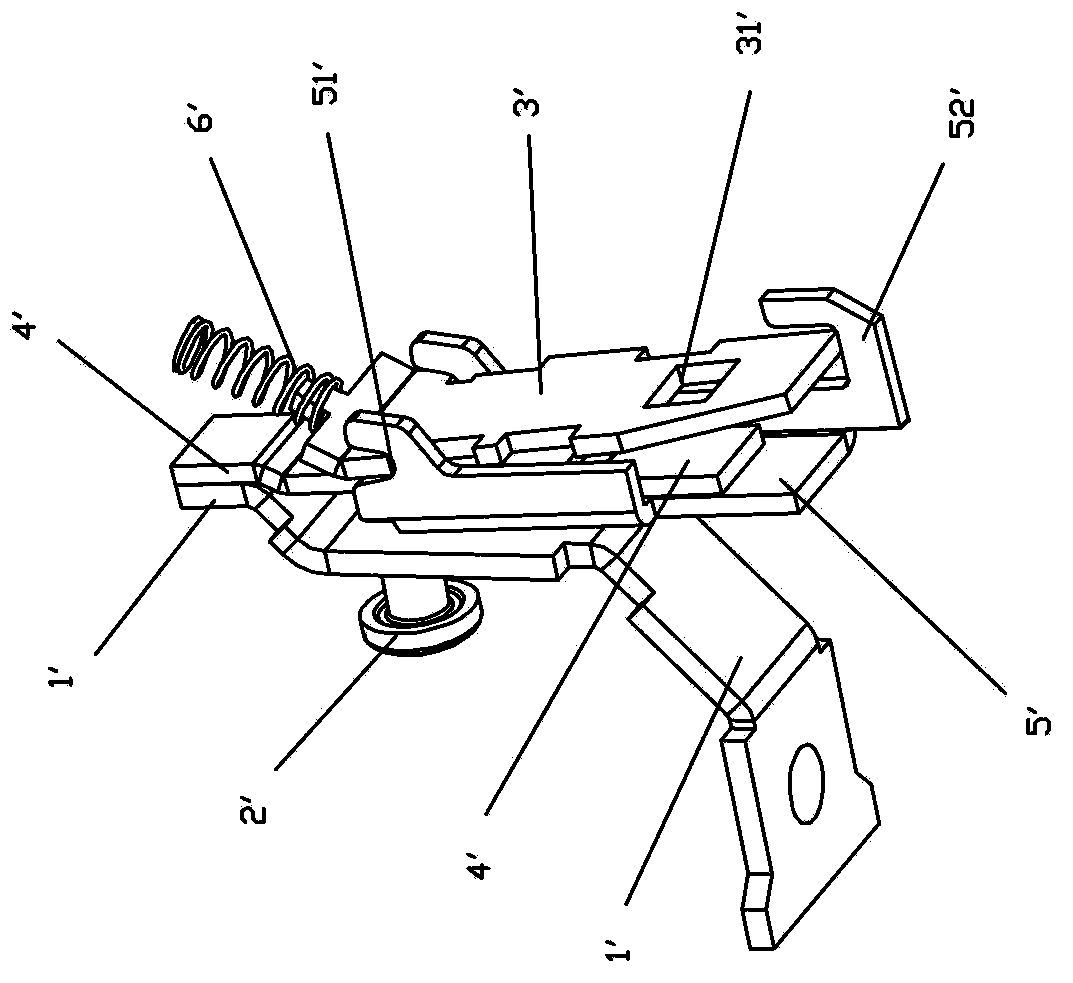

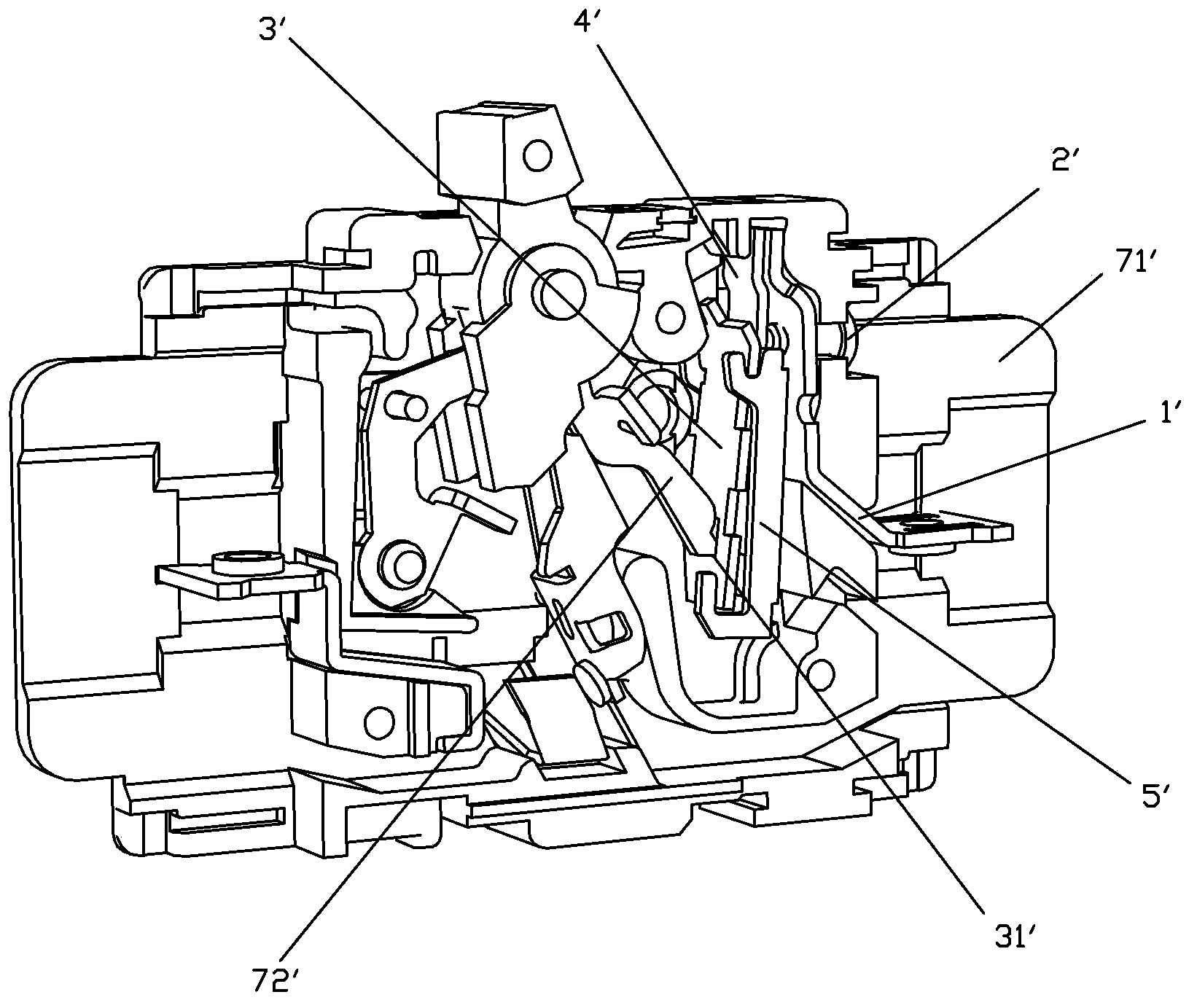

[0027] Examples, see Figure 5 to Figure 7 As shown, a thermal-magnetic protection device of the present invention is used on a circuit breaker. The thermal-magnetic protection device includes a terminal board 1, an adjusting screw 2, an armature 3, a bimetallic element 4, a yoke 5 and a reaction spring 6 The wiring board 1 is fixed on the preset support body; the armature 3 is suspended in the groove 51 of the yoke 5, and the upper part of the armature 3 is fixed on the preset support body through the reaction force spring 6; it also includes A twisted wire 7; one end 52 of the yoke is clamped on a preset support body, and the other end 53 is elastically bent so as to have a preset angle a with the first end 52, the The adjustment screw 2 is screwed on one end 52 of the yoke, and the end of the adjustment screw 2 is against the other end 53 of the yoke with elastic force, so as to adjust the preset angle a through the adjustment screw. size; the bimetallic element 4 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com