Lignin/polyether polyol impact-resistant and self-healing coating and preparation method thereof

A technology of polyether polyol and lignin, which is applied in the direction of lignin coating, polyether coating, coating, etc., can solve the problems of complex preparation process, poor impact strength, non-self-healing, etc., and achieve simple and efficient preparation process , Improve green properties, good adhesion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

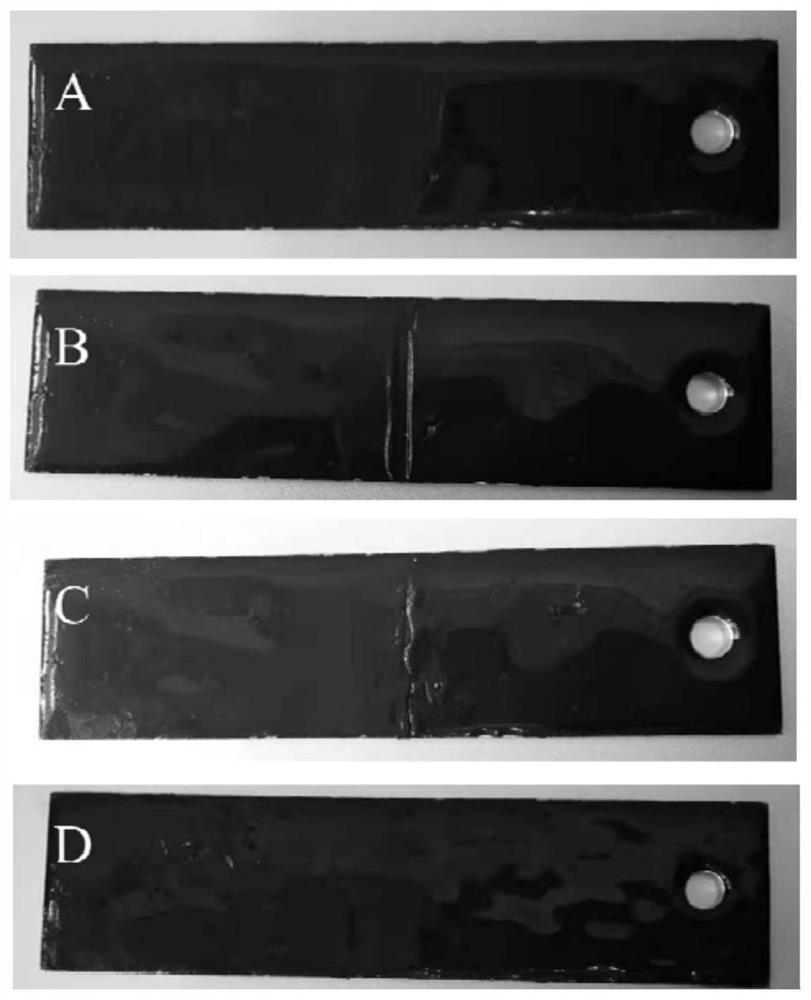

Image

Examples

Embodiment 1

[0069] (1) Weigh 25g of lignin, dissolve it in 1L of 0.1M NaOH solution, and then slowly add 0.1M dilute HCl solution dropwise with a peristaltic pump under the conditions of stirring speed of 100rpm and temperature of 30°C for acid precipitation, adding The acid settling time is 2h until the lignin is precipitated;

[0070] (2) Centrifuge, pour off the supernatant, place the lignin precipitate in a 1000Da dialysis bag, soak and wash the dialysis bag in running water for 24 hours, repeat the dialysis 3 times, and freeze-dry to obtain a high-purity product with a purity of more than 99.7%. Lignin;

[0071] (3) Dissolve the high-purity lignin obtained in step (2) in 0.1M NaOH solution, and perform ultrafiltration using an ultrafiltration device: first, use a filter membrane with Mw=8000 to ultrafilter, and take out the lignin base with Mw>8000 solution, and then it is ultrafiltered by a filter membrane with Mw=10000, and the filtrate is taken out to be a high-purity lignin solu...

Embodiment 2

[0077] (1) Weigh 25g of lignin, dissolve it in 1L of 0.1M NaOH solution, and then slowly add 0.1M dilute HCl solution dropwise with a peristaltic pump under the conditions of stirring speed of 100rpm and temperature of 30°C for acid precipitation, adding The acid settling time is 2h until the lignin is precipitated;

[0078](2) Centrifuge, pour off the supernatant, place the lignin precipitate in a 1000Da dialysis bag, soak and wash the dialysis bag in running water for 24 hours, repeat the dialysis 3 times, and freeze-dry to obtain a high-purity product with a purity of more than 99.7%. Lignin;

[0079] (3) Dissolve the high-purity lignin obtained in step (2) in 0.1M NaOH solution, and perform ultrafiltration with an ultrafiltration device: first use a filter membrane with Mw=5000 to ultrafilter, and take out the lignin base with Mw>5000 solution; then it is ultrafiltered by a filter membrane of Mw=8000, and the filtrate is taken out to be a high-purity lignin solution of Mw...

Embodiment 3

[0085] (1) Weigh 25g of lignin, dissolve it in 1L of 0.1M NaOH solution, and then slowly add 0.1M dilute HCl solution dropwise with a peristaltic pump under the conditions of stirring speed of 100rpm and temperature of 30°C for acid precipitation, adding The acid settling time is 2h until the lignin is precipitated;

[0086] (2) Centrifuge, pour off the supernatant, place the lignin precipitate in a 1000Da dialysis bag, soak and wash the dialysis bag in running water for 24 hours, repeat the dialysis 3 times, and freeze-dry to obtain a high-purity product with a purity of more than 99.7%. Lignin;

[0087] (3) Dissolve the high-purity lignin obtained in step (2) in 0.1M NaOH solution, and perform ultrafiltration with an ultrafiltration device: first, use a filter membrane with Mw=4000 to ultrafilter, and take out the lignin base with Mw>4000 solution; then it is ultrafiltered by a filter membrane with Mw=5000, and the filtrate is taken out to be a high-purity lignin solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com