Magneto-Rheological Damping Device for Discharge Door of Internal Mixer

A magnetorheological damping and magnetorheological damper technology, applied in mechanical equipment, springs, shock absorbers, etc., can solve problems such as affecting the service life of the door shaft and the mixer, large acceleration of the discharge door, and increased cost. , to achieve the effect of simple structure, large impact resistance and saving maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

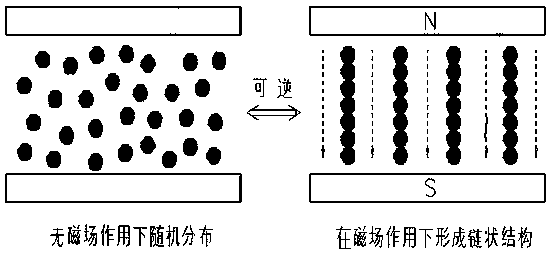

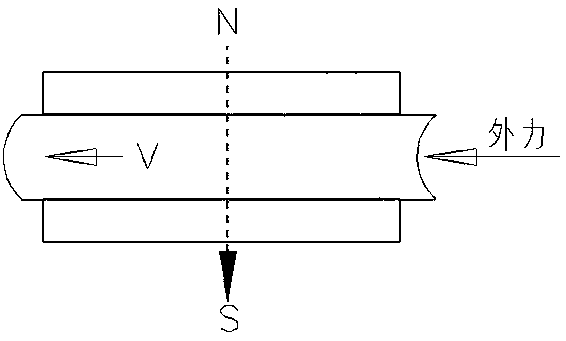

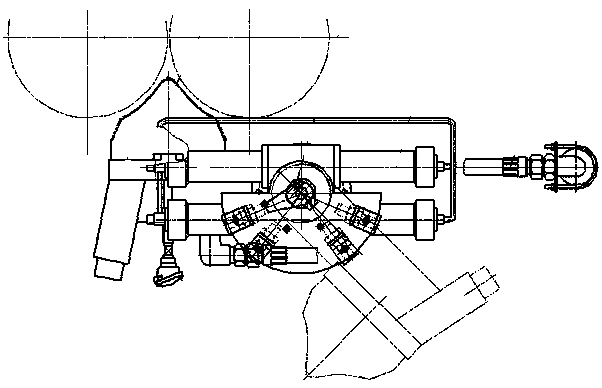

[0015] Such as figure 1 with figure 2 As shown, magnetorheological technology is a new technology developed on the basis of an innovative material and magnetorheological fluid being widely used in recent years. This new type of intelligent material with unique functions mainly includes micron-sized soft magnetic particles, non-magnetic Magnetic carrier liquid and additives, conventional soft magnetic particles are iron-cobalt alloy, iron-nickel alloy, pure iron powder and hydroxyl iron powder, etc., non-magnetic carrier liquid mainly includes silicone oil, mineral oil, synthetic oil, water and ethylene glycol Alcohol, etc., the additives are generally surfactants, protective colloidal substances, such as oleic acid, silica gel, silicon oxide, etc., whose function is to prevent the soft magnetic particles and the carrier liquid from agglomeration and precipitation due to the difference in density. The magnetorheological damping device developed has the advantages of simple st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com