Frequency selection, electromagnetic shielding, heat insulation, light weight and impact resistance integrated three-dimensional fabric composite material and preparation method thereof

A three-dimensional fabric, electromagnetic shielding technology, applied in the direction of fabrics, multi-strand fabrics, textiles, etc., can solve the problems of inability to meet the mechanical performance requirements of industrial design composite materials, little research on electromagnetic shielding, and poor shear resistance. Integrated design of structure and function, easy to promote and use, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Carbon fiber three-dimensional spacer yarn fabric / polyurethane (PU) foam composite material

[0049] The carbon fiber three-dimensional spacer yarn fabric uses carbon fiber as its warp, weft and spacer yarns, and the fineness is 198tex. The upper and lower layers are alternately interlaced up and down in plain weave, and the height of the spacer yarns is controlled by using spacers (the height range is usually between 0.5mm-2mm), and the spacer yarns that participate in the weaving of the upper layer move to the lower layer to participate in the lower layer along with the palm frame. For the weaving of the lower layer, the spacer yarn that participates in the weaving of the lower layer moves to the upper layer with the palm frame to participate in the weaving of the upper layer, and then continues the weaving of the upper and lower layers; until the next part that needs to be tied, repeat the above operation, and the spacer yarn is " The 8" shape props up the upper and ...

Embodiment 2

[0054] Carbon fiber spacer yarn fabric / PMMA expanded microspheres@epoxy resin composite material

[0055] The weaving method and pretreatment of the carbon fiber spacer yarn fabric are the same as in Example 1.

[0056] Weigh 2g of PMMA heat-expandable microspheres and mix them evenly with 4g of amine curing agent. The amine curing agent is aliphatic amine with an active hydrogen equivalent of 60g / eq. Use mechanical stirring at 1000rpm to mix evenly for 5min to obtain mixed solution 1, then weigh 8g of epoxy resin and The above mixed solution was uniformly mixed, and mechanically stirred at 1000 rpm for 10 minutes to obtain mixed solution 2. Inject the mixed solution 2 into the reserved injection port, seal the mold, put it in an oven at 120°C, take it out after 1 hour, and demould after cooling at room temperature to obtain carbon fiber spacer yarn / PMMA expanded microsphere@epoxy resin composite material.

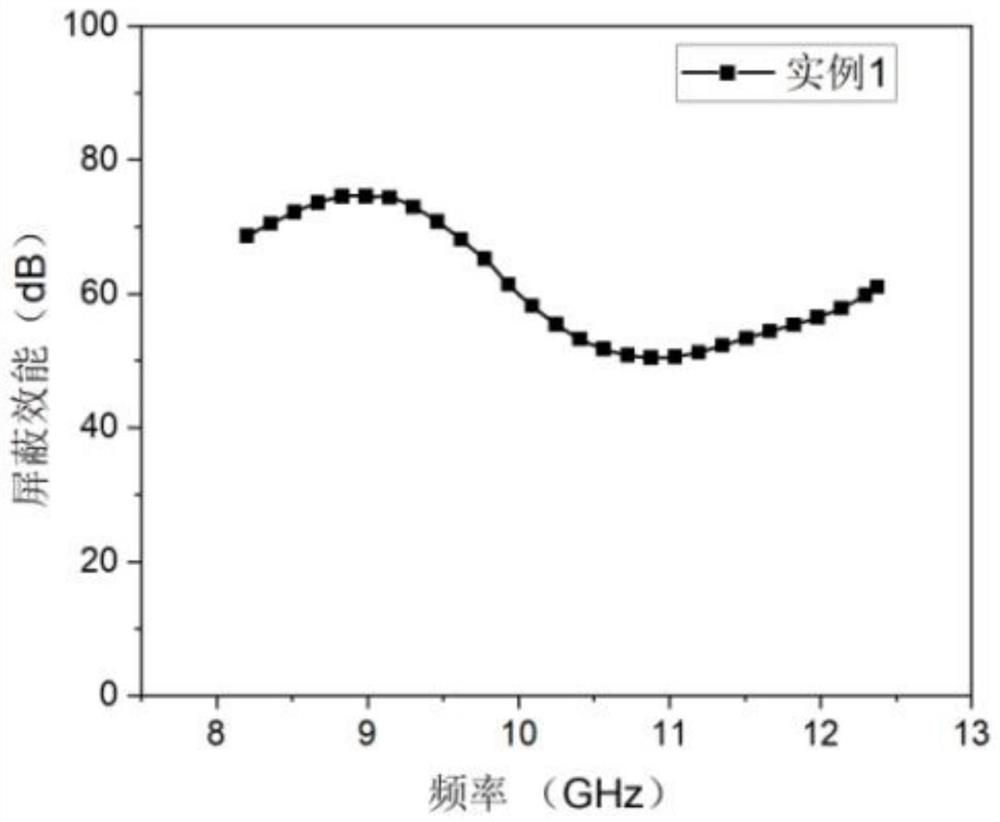

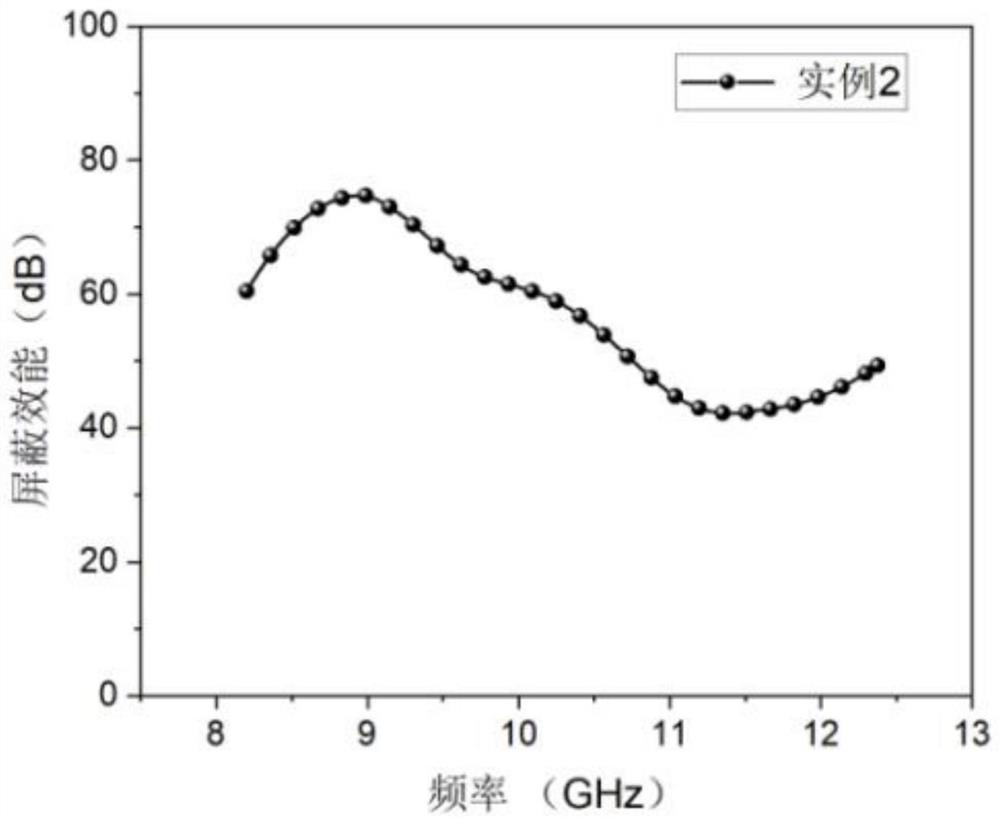

[0057] After testing, the shielding effectiveness curve of the carbo...

Embodiment 3

[0059] Carbon Fiber Spacer Yarn Fabric / Conductive Foam Composite

[0060] The weaving method and pretreatment of the carbon fiber spacer yarn fabric are the same as in Example 1.

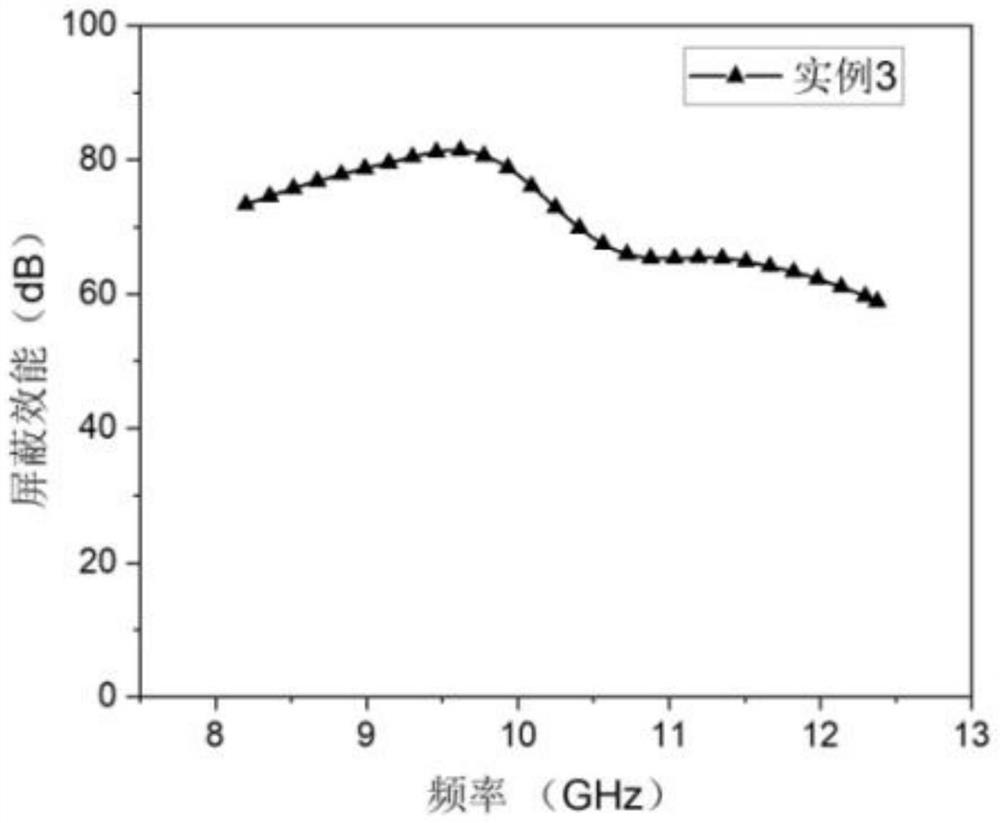

[0061] Weigh 10g of PMMA heat-expandable microspheres, add them into 50mL of concentrated sulfuric acid, stir continuously for 60min roughening treatment, wash repeatedly, and dry for later use. Disperse GA in ethanol at a ratio of 2 mg / mL, and perform ultrasonic treatment for 30 min to obtain a GA ethanol dispersion. Put the PMMA heat-expandable microspheres after the above treatment into 30mL of 2mg / mL GA ethanol dispersion, put them into a water bath at 70°C, and keep stirring until the ethanol evaporates to dryness. During this process, GA will be uniformly deposited After being coated on the surface of PMMA heat-expandable microspheres, GA / PMMA heat-expandable microspheres are finally obtained. Weigh 2g of GA / PMMA heat-expandable microspheres and mix them evenly with 4g of amine curing agent....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com