Casting-forging combined torsion-resistant anti-impact vehicle steering knuckle and manufacturing method thereof

A steering knuckle and anti-torsion technology, which is applied to steering mechanisms, steering rods, vehicle components, etc., can solve the problems of poor fatigue resistance, poor torsion resistance, and high technological difficulty, and achieve the ability to resist axial stretching and extrusion. The effect of strong, improved performance, and low process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A steering knuckle for a vehicle with casting and forging combined with anti-torsion and impact resistance. The steering knuckle has a porosity of 0%-0.2%, and the grain growth direction is generally horizontal from the outermost edge to the center of the axis. The material used is ZGD730-910;

[0027] The manufacturing method of the above-mentioned casting and forging combined anti-torsion and impact-resistant vehicle steering knuckle includes the following steps:

[0028] 1) Preparation before manufacturing

[0029] ① Raw material preparation: prepare sufficient quantities of low-alloy steel ingots for design;

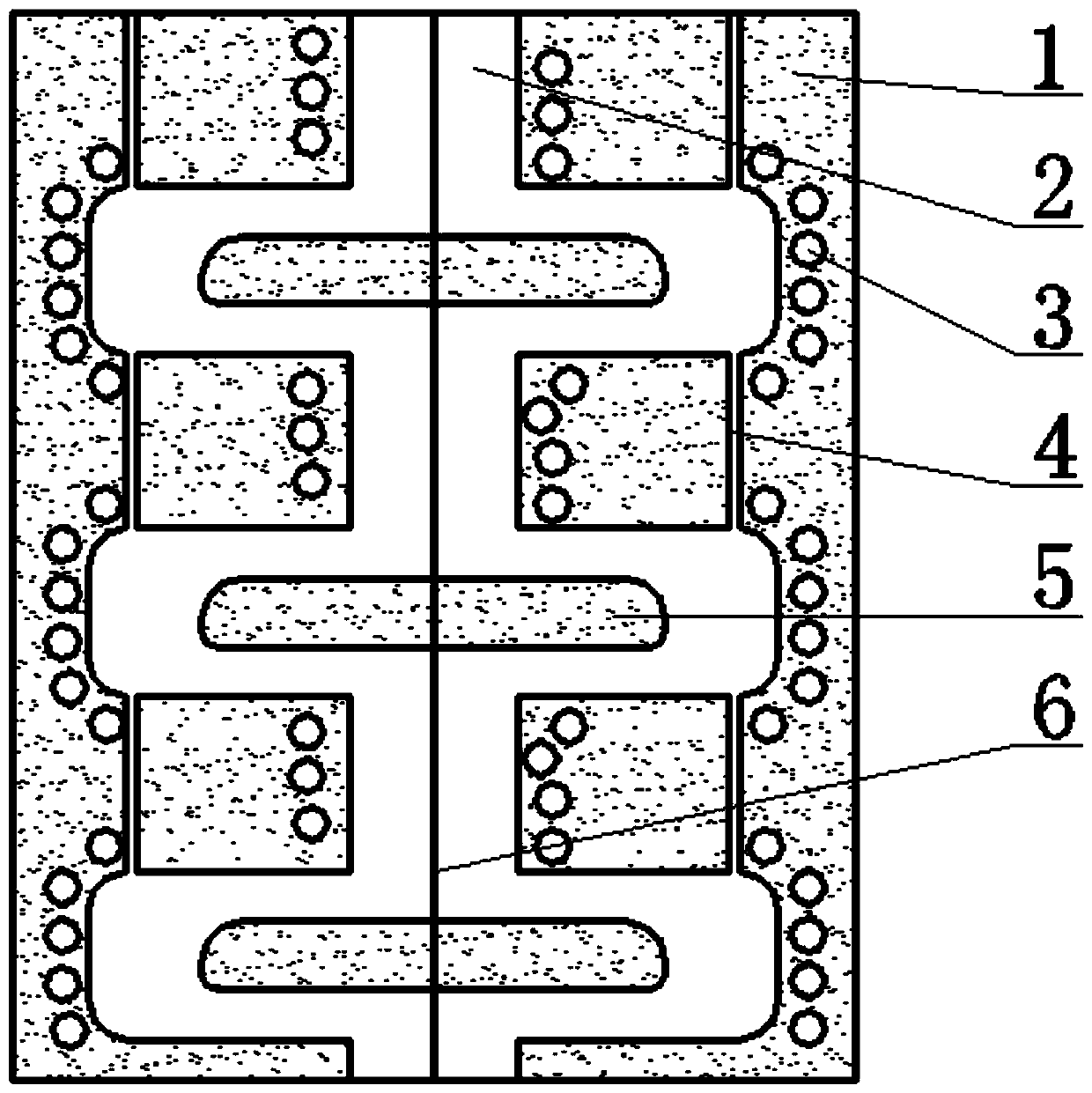

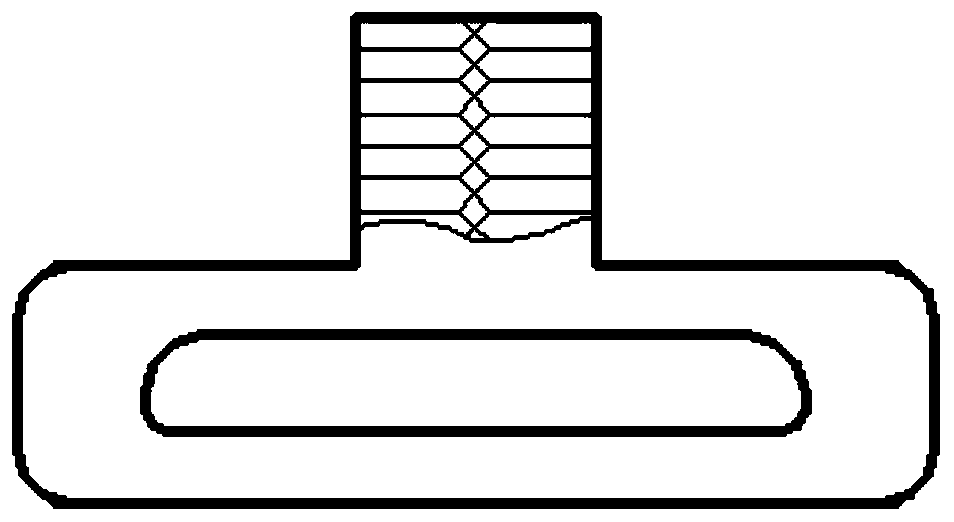

[0030] ② Tooling preparation: Prepare a water-cooled steel mold rotary casting mold. The mold is composed of two half-moulds. The mold parting surface 6 is located on the center line of both sides of the symmetry. The mold entity is the matrix 1, which is made of graphite. Font-X-shaped circular communication, wherein the I-shaped corresponds to the central s...

Embodiment 2

[0040] The whole is consistent with Example 1, the difference is:

[0041] The material used for the steering knuckle is ZGD345-570;

[0042] The manufacturing method of the above-mentioned casting and forging combined anti-torsion and impact-resistant vehicle steering knuckle includes the following steps:

[0043] 1) Preparation before manufacturing

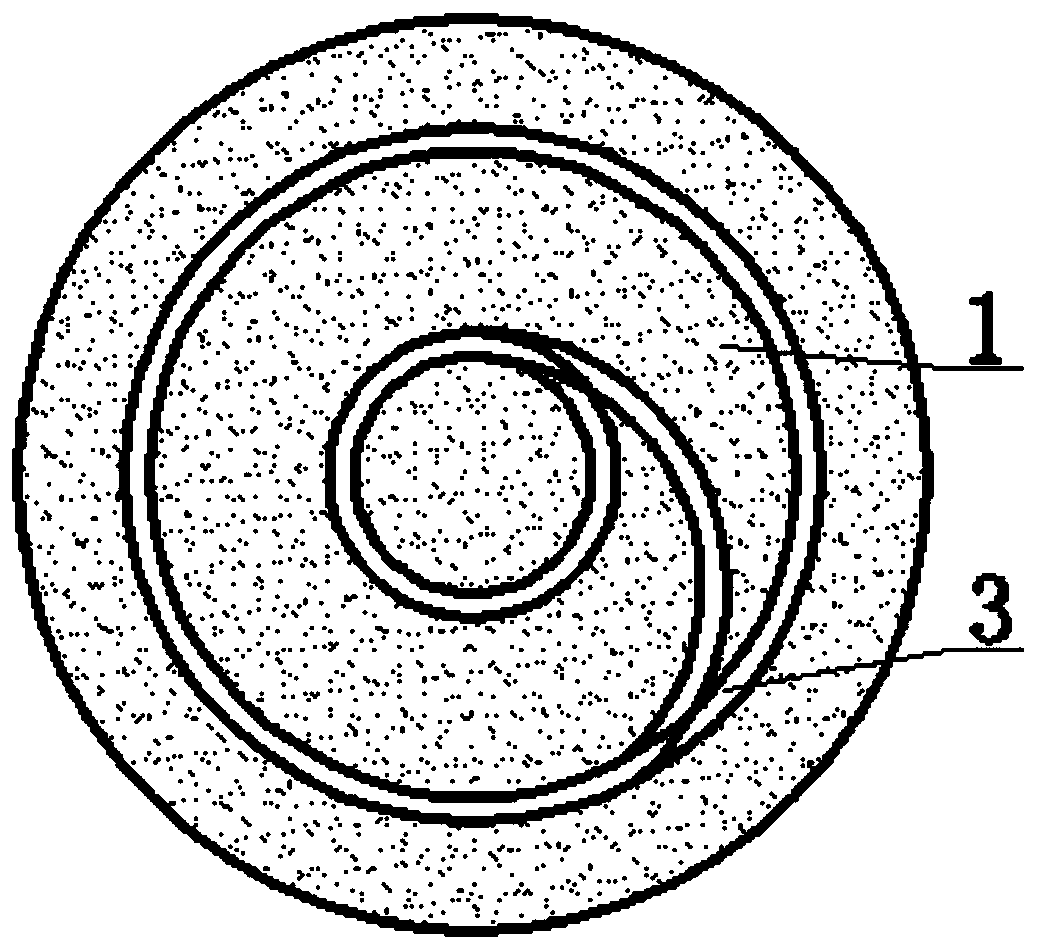

[0044] ②Tooling preparation: The base body 1 is provided with a circulating water channel 3 on the radially outer side of the runner 2 and close to the runner 1.2cm; prepare a single-section inner cavity size that is 3% larger than the design outline size of the steering knuckle, and the inner surface is 10 layers of nickel foil of;

[0045] 2) casting

[0046] ① Spray the two parting molds of the water-cooled steel mold rotary casting mold prepared in stage 1) and step ②, respectively, spray the mold parting agent, combine and assemble them, and then install and fix them on the rotating chassis in the furnace to correspond t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com