Functionalized TPU special powder for SLS molding anti-impact anti-exposure automobile instrument panel and preparation method of functionalized TPU special powder

An instrument panel and impact-resistant technology, applied in the field of functionalized TPU powder, can solve the problems of very little research and development of TPU powder materials and complex shapes, and achieve the effects of excellent comprehensive product performance, improved precision and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) 100 parts by mass of TPU special powder material, 10 parts by mass of impact-resistant filler, 10 parts by mass of anti-exposure filler, 5 parts by mass of nano-silica, 2 parts by mass of antioxidant, 1 part by mass of stabilizer, talcum powder 10 parts by mass, 2 parts by mass of coupling agent, and 1 part by mass of weather resistance agent were put into a high-speed mixer at 1200 r / min, and blended for 15 minutes.

[0055] (2) SLS forming standard splines, set SLS process parameters, preheating temperature 140°C, scanning distance 0.20mm, laser power 25W, powder coating thickness 0.20mm, scanning speed 9000mm / s.

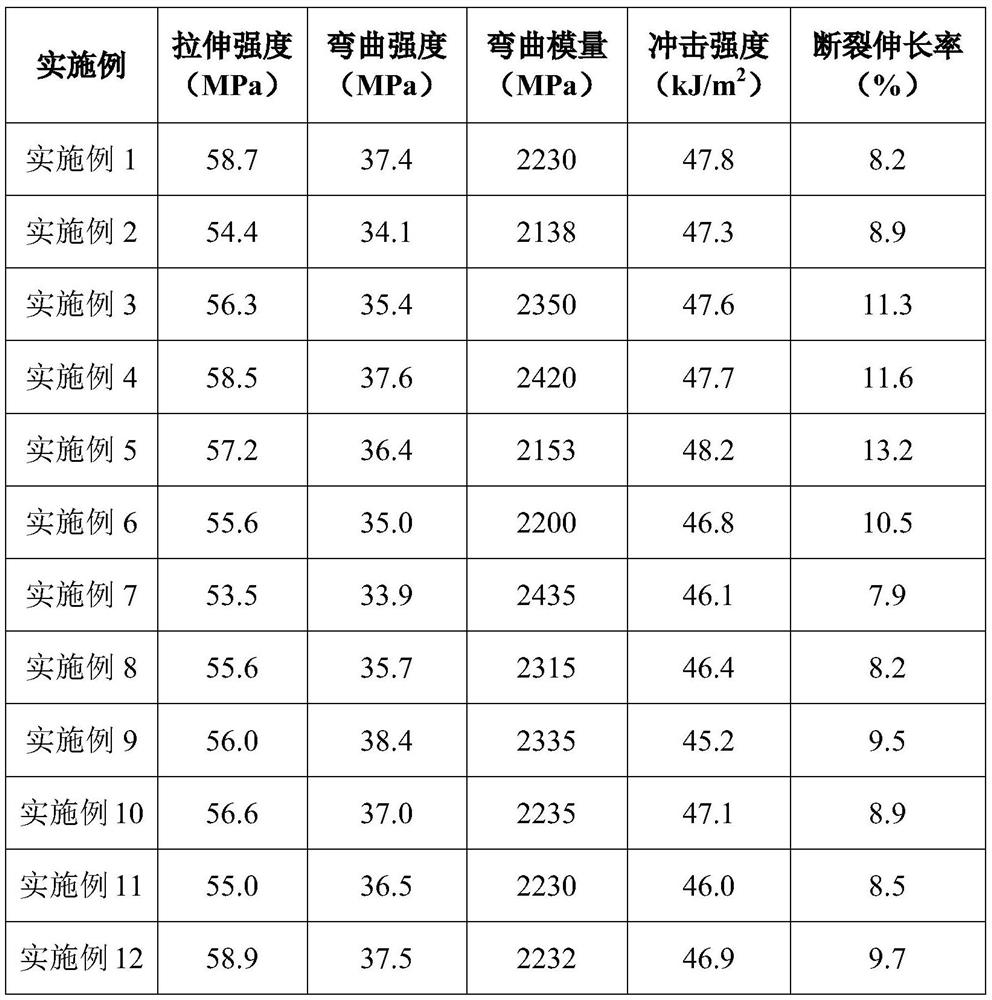

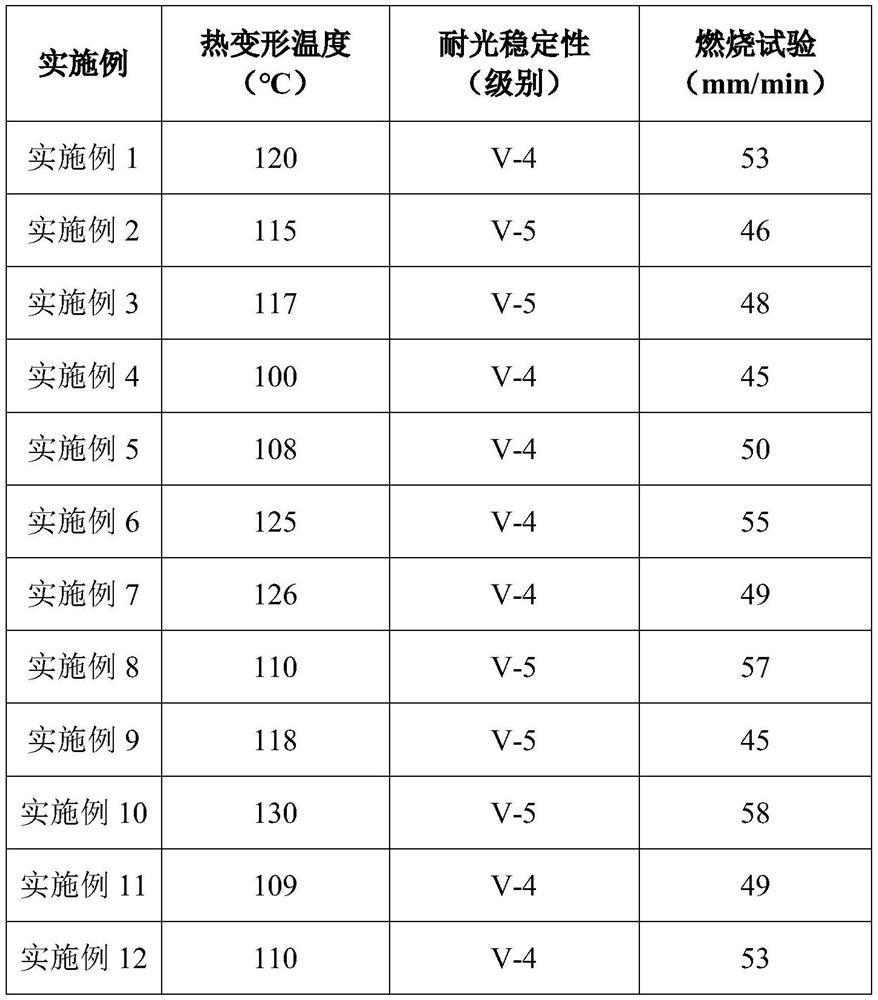

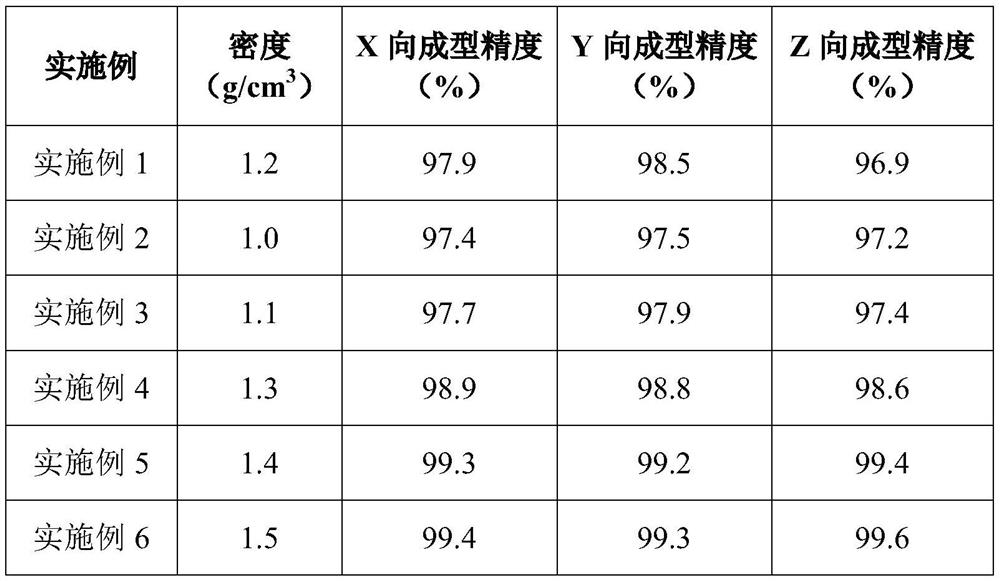

[0056] (3) Carry out mechanical performance test (impact strength test according to GB / T1043-93, sample tensile test according to GB / T1040-92) and thermal stability test (TGA test) on the formed standard sample.

[0057] In this experimental example, the anti-exposure filler is the anti-exposure modified filler prepared in the above experiment, the anti...

Embodiment 2

[0059] (1) 100 parts by mass of TPU special powder material, 15 parts by mass of anti-shock filler, 15 parts by mass of anti-exposure filler, 5 parts by mass of nano silicon dioxide, 2 parts by mass of antioxidant, 1 part by mass of stabilizer, talcum powder 10 parts by mass, 2 parts by mass of coupling agent, and 1 part by mass of weather resistance agent were put into a high-speed mixer at 1200 r / min, and blended for 15 minutes.

[0060] (2) SLS forming standard splines, set SLS process parameters, preheating temperature 140°C, scanning distance 0.20mm, laser power 25W, powder coating thickness 0.20mm, scanning speed 9000mm / s.

[0061] (3) Carry out mechanical performance test (impact strength test according to GB / T1043-93, sample tensile test according to GB / T1040-92) and thermal stability test (TGA test) on the formed standard sample.

[0062] In this experimental example, the anti-exposure filler is the anti-exposure modified filler prepared in the above experiment, the a...

Embodiment 3

[0064] (1) 100 parts by mass of TPU special powder material, 20 parts by mass of impact-resistant filler, 20 parts by mass of anti-exposure filler, 5 parts by mass of nano-silica, 2 parts by mass of antioxidant, 1 part by mass of stabilizer, talcum powder 10 parts by mass, 2 parts by mass of coupling agent, and 1 part by mass of weather resistance agent were put into a high-speed mixer at 1200 r / min, and blended for 15 minutes.

[0065] (2) SLS forming standard splines, set SLS process parameters, preheating temperature 140°C, scanning distance 0.20mm, laser power 25W, powder coating thickness 0.20mm, scanning speed 9000mm / s.

[0066] (3) Carry out mechanical performance test (impact strength test according to GB / T1043-93, sample tensile test according to GB / T1040-92) and thermal stability test (TGA test) on the formed standard sample.

[0067] In this experimental example, the anti-exposure filler is the anti-exposure modified filler prepared in the above experiment, the anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com