High-wear-resisting cold roll and manufacturing method thereof

A manufacturing method and technology for cold rolling rolls, applied in the field of roll manufacturing, can solve problems such as poor wear resistance, and achieve the effects of high comprehensive mechanical properties, good metallurgical quality, and moderate grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The manufacturing method of the high wear-resistant cold rolling roll of the present embodiment comprises the following steps,

[0028] 1) Prepare steel raw materials according to the chemical composition and weight percentage in the material of the cold roll, and prepare the roll blank according to the roll blank production process.

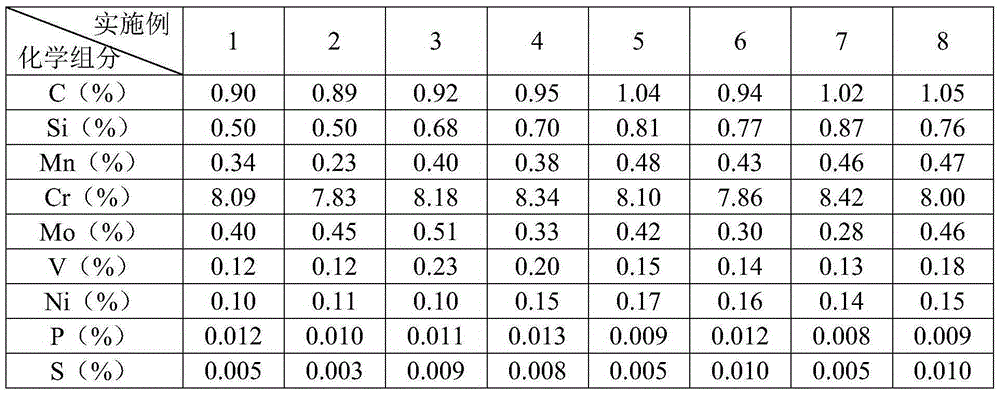

[0029] Specifically, steel raw materials are smelted in electric arc furnaces and LF / VD refining furnaces, and cast into electrode ingots. Micro-alloying treatment is carried out by adding trace elements in the medium, and the chemical composition and weight percentage of the remelted electrode ingot are tested. After passing the test, it is forged into a forging billet. Roll blanks are obtained by turning.

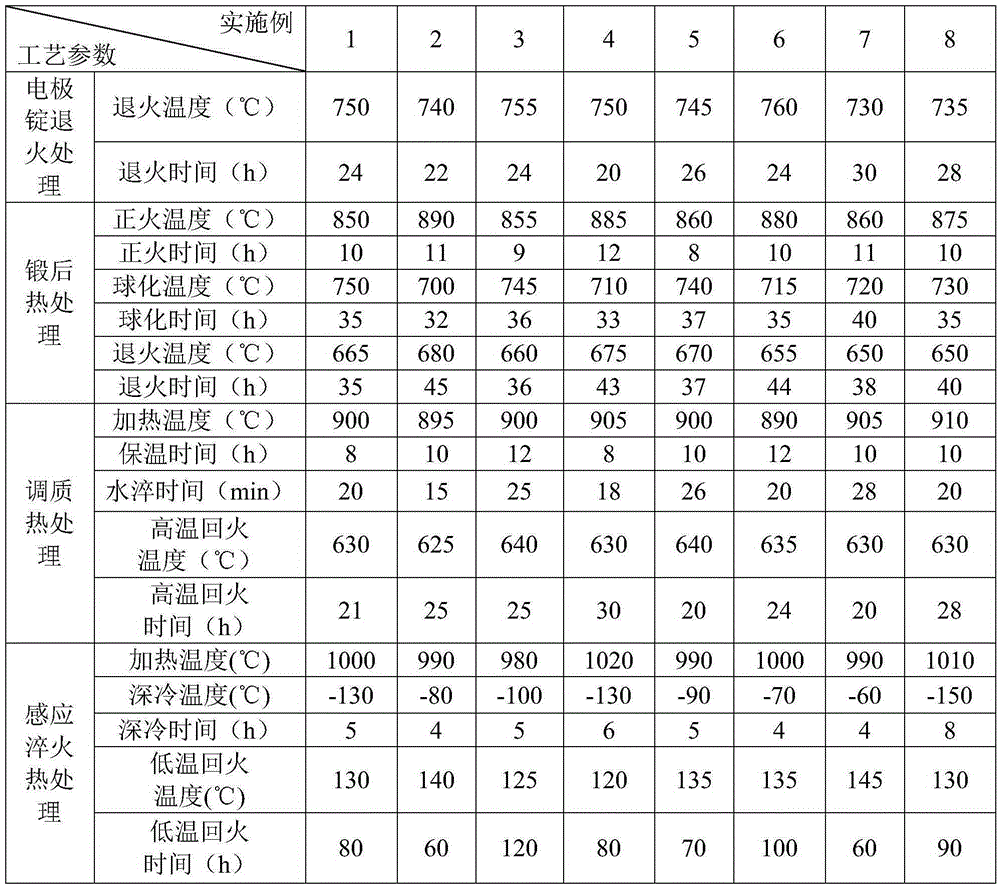

[0030] The annealing temperature of the electrode ingot annealing treatment is 750°C, and the annealing time is 24h. Post-forging heat treatment includes normalizing treatment and spheroidizing annealing treatment. The normalizing ...

Embodiment 2

[0039] The high wear-resistant cold rolling roll of this embodiment, the weight percentage of various chemical components in its material is tested, and the content of main components is shown in column 2 of Example 2 in Table 1, and the rest is Fe and unavoidable impurities .

[0040] The manufacturing method of the high wear-resistant cold rolling roll of this embodiment has similar process steps to that of Embodiment 1, and the specific heat treatment parameters different from Embodiment 1 are shown in column 2 of Embodiment 2 in Table 2.

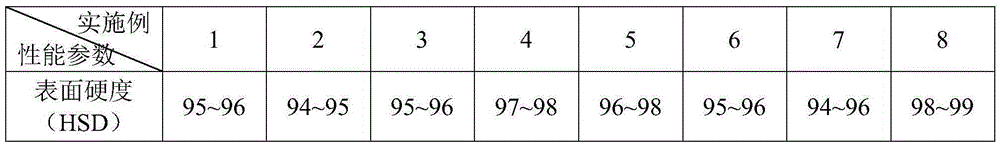

[0041] The cold roll produced in this embodiment has a roll surface hardness of 94-95HSD.

Embodiment 3

[0043] The high wear-resistant cold rolling roll of this embodiment, the weight percentage of various chemical components in its material is tested, and the content of main components is shown in column 3 of Example 1 in Table 1, and the rest is Fe and unavoidable impurities .

[0044] The manufacturing method of the high wear-resistant cold roll of this embodiment has similar process steps to that of Embodiment 1, and the specific heat treatment parameters different from Embodiment 1 are shown in column 3 of Embodiment 2 in Table 2.

[0045] The cold rolled roll prepared in this embodiment has a roll surface hardness of 95-96 HSD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com