Double-film inflated bag and manufacturing method thereof

A manufacturing method and a technology for inflatable bags, which are applied in the manufacture of flexible containers, bags, sacks, etc., can solve the problems of wasted man-hours, cumbersome operation procedures, waste of materials, etc., so as to save operation steps, reduce manual operations, and facilitate environmental protection. The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

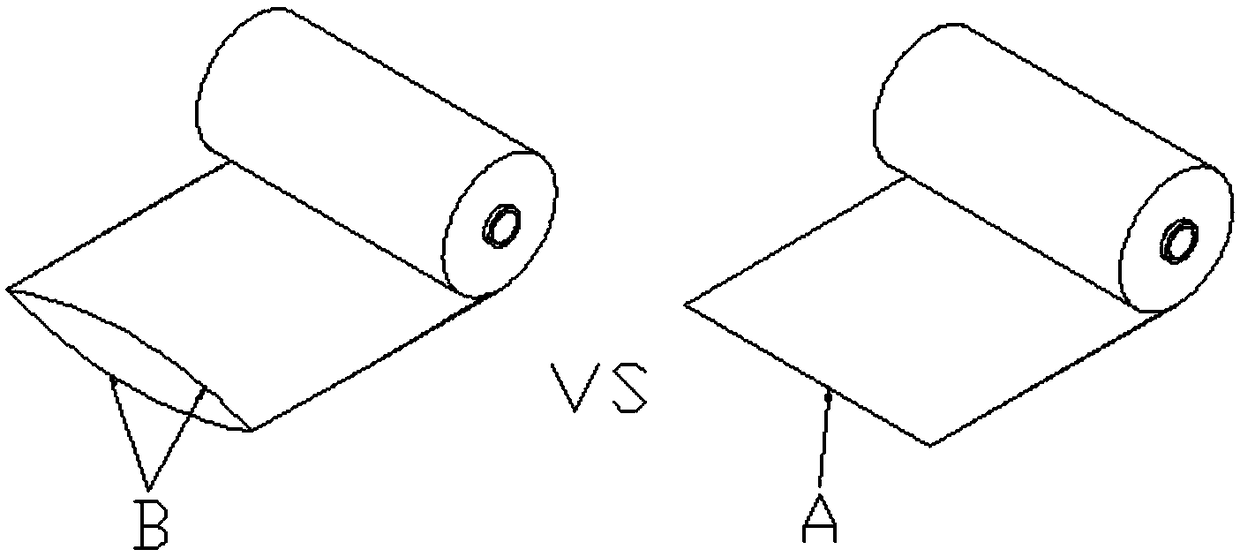

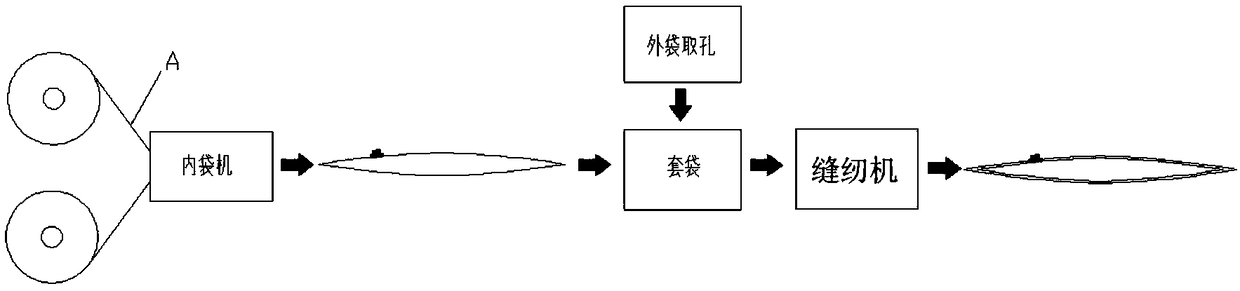

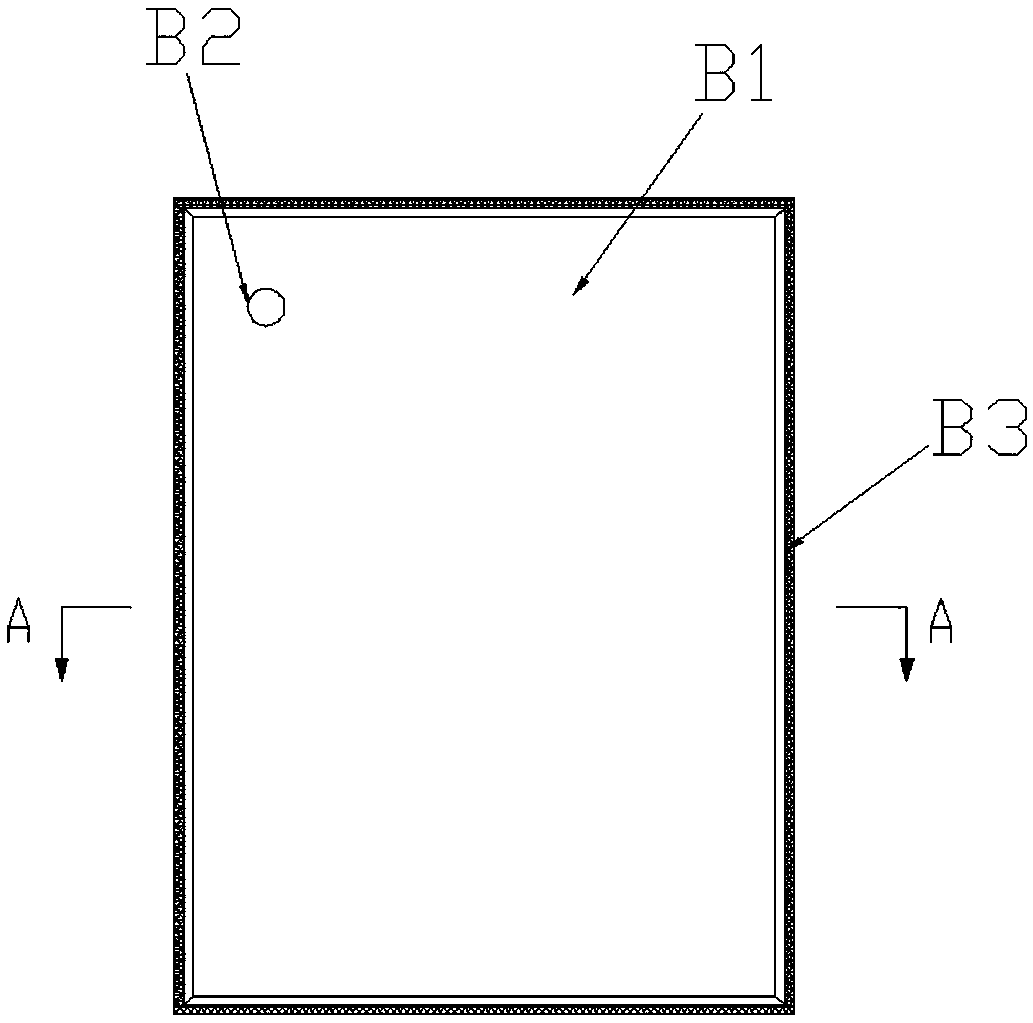

[0028] The biggest difference between the double-membrane inflatable bag of the present invention and the traditional inflatable bag is that the bag body of the double-membrane inflatable bag in the present invention is welded and packaged by two tube film materials; the tube film material B used in it is Such as figure 1 As shown, its structure is a double-layer film; specifically, it is formed by a cylindrical film directly blown out by a film blowing equipment, and then directly wound by a reel machine. The traditional inflatable bag includes an inner bag and an outer bag, and most inner bags are made of plastic film, while the outer bag is made of kraft paper material, and the inner bag is made of such as figure 1 Made of monolithic membrane material. The production process of traditional inflatable bags is as follows: figure 2 As shown, two pieces of single-pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com