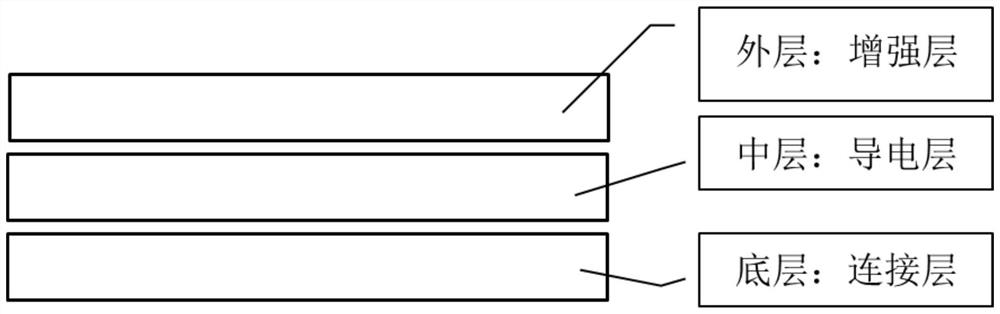

Preparation method of electromagnetic shielding composite film layer based on non-metallic material

A non-metallic material, electromagnetic shielding technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of conductive coatings such as lack of magnetic permeability, complicated process control, and poor environmental stress resistance performance, and achieve simple and easy preparation process steps Easy to use, simple manufacturing process and high implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Step 1: Degreasing and cleaning polyphenylene sulfide PPS parts

[0017] Step 2: Direct electroless nickel plating, thickness 5-8μm

[0018] Step 3: Electroplate nickel parts with a thickness of 15-20μm

[0019] Using this treatment method, the surface inertia of polyphenylene sulfide itself leads to insufficient bonding force of the coating. During the test of the simulated use process such as temperature shock, the coating falls off due to the poor bonding force of the bottom coating, which affects product reliability.

Embodiment 2

[0021] Step 1: Degreasing and cleaning PEEK parts

[0022] Step 2: Spray conductive paint directly on the surface of the workpiece, with a thickness of 80-100 μm

[0023] Step 3: Spray acrylic polyurethane or fluoropolyurethane on the surface of the workpiece as a protective coating

[0024] With this treatment method, the conductive coating on the inner surface of the part may be exposed to oxidation for a long time, and it may fail to oxidize. In order to have good electromagnetic shielding performance, a thicker conductive coating needs to be sprayed to increase the weight of non-metallic parts.

Embodiment 3

[0026] Step 1: Degreasing and cleaning carbon fiber composite parts

[0027] Step 2: Spray conductive paint directly on the surface of the workpiece, with a thickness of 20-40 μm

[0028] Step 3: electroplating nickel parts with a thickness of 15-20 μm

[0029] With this treatment method, there are small hole defects on the surface of the carbon fiber composite material. During the electroplating process, the air in the hole is heated and expanded, resulting in blistering of the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com