A thermally conductive shielding silicone material and preparation method thereof

A technology of organic silicon and flexible materials, which is applied in the field of thermally conductive shielding multifunctional organic silicon materials and its preparation, can solve the problems of multi-contact thermal resistance of thermally conductive particles, the inability to obtain light-weight and high-thermal-conductivity thermal interface materials, and achieve the elimination of contact heat Resistance, simplified assembly structure and volume, good plane shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

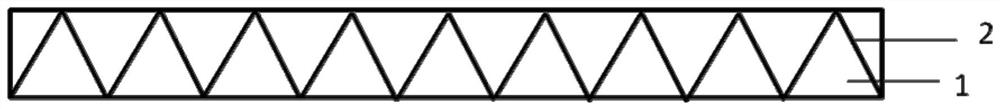

[0041] A preparation method of corrugated silicone graphene composite material (corrugated paper core thickness 10mm):

[0042] (1) Using a 25 μm graphene film as the raw material paper, a wave-shaped foldable and stretchable core material is made by a wave folding device;

[0043] (2) The wave-shaped folded core material is compressed and placed in a mold to be pressed and shaped, then liquid silicone rubber is poured, vacuumed to remove bubbles, and cured at 150°C for 30 minutes to obtain a silicone composite material for heat conduction shielding. The composition and weight ratio of the liquid silicone rubber are as follows: 100 parts by weight of 1000 mPa·s vinyl-terminated polysiloxane, 5.5 parts by weight of methyl hydrogen polysiloxane crosslinking agent, 0.3 parts by weight of platinum catalyst, 0.2 parts by weight Butynol inhibitor in parts by weight and KH-560 surface treatment agent in 1.5 parts by weight are mixed to form liquid silica gel. The thermal conductivit...

Embodiment 2

[0045] A preparation method of corrugated organosilicon-graphite composite material (corrugated paper core thickness 5mm):

[0046] (1) 25 μm graphite film is used as the raw material paper, and a wave-shaped foldable and stretchable core material is made by a wave folding device;

[0047] (2) The wave-shaped folded core material is compressed and placed in a mold to be pressed and shaped, then liquid silicone rubber is poured, vacuumed to remove bubbles, and cured at 150°C for 30 minutes to obtain a silicone composite material for heat conduction shielding. The composition and weight ratio of the liquid silicone rubber are as follows: 100 parts by weight of 5000mPa·s vinyl-terminated polysiloxane, 2.5 parts by weight of methyl hydrogen polysiloxane crosslinking agent, 0.2 parts by weight of platinum catalyst, 0.1 parts by weight Butynol inhibitor in parts by weight and KH-560 surface treatment agent in 3.0 parts by weight are mixed to form liquid silica gel. The thermal cond...

Embodiment 3

[0049] A preparation method of corrugated silicone graphite / graphene composite material (corrugated paper core thickness 2mm):

[0050] (1) Using a 17 μm graphene film as the raw material paper, a wave-shaped foldable and stretchable core material is made by a wave folding device;

[0051] (2) The wave-shaped folded core material is compressed and placed in a mold to be pressed and shaped, then liquid silicone rubber is poured, vacuumed to remove bubbles, and cured at 150°C for 30 minutes to obtain a silicone composite material for heat conduction shielding. The ingredients and parts by weight ratio of liquid silicone rubber are as follows: 100 parts by weight of 3000mPa·s vinyl-terminated polysiloxane, 3.5 parts by weight of methyl hydrogen polysiloxane crosslinking agent, 0.5 parts by weight of platinum catalyst, 0.1 parts by weight Butynol inhibitor in parts by weight and KH-560 surface treatment agent in 2.0 parts by weight are mixed to form liquid silica gel. The thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com