Electromagnetic shielding plastic and preparation method thereof

An electromagnetic shielding and plastic technology, which is applied in the field of electromagnetic shielding plastics and its preparation, can solve the problems of material shielding performance, unsatisfactory mechanical properties, no absorption loss of electromagnetic waves, and difficulty in obtaining shielding functions, etc., to achieve good electromagnetic shielding effect and equipment Less dependence, good weather resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

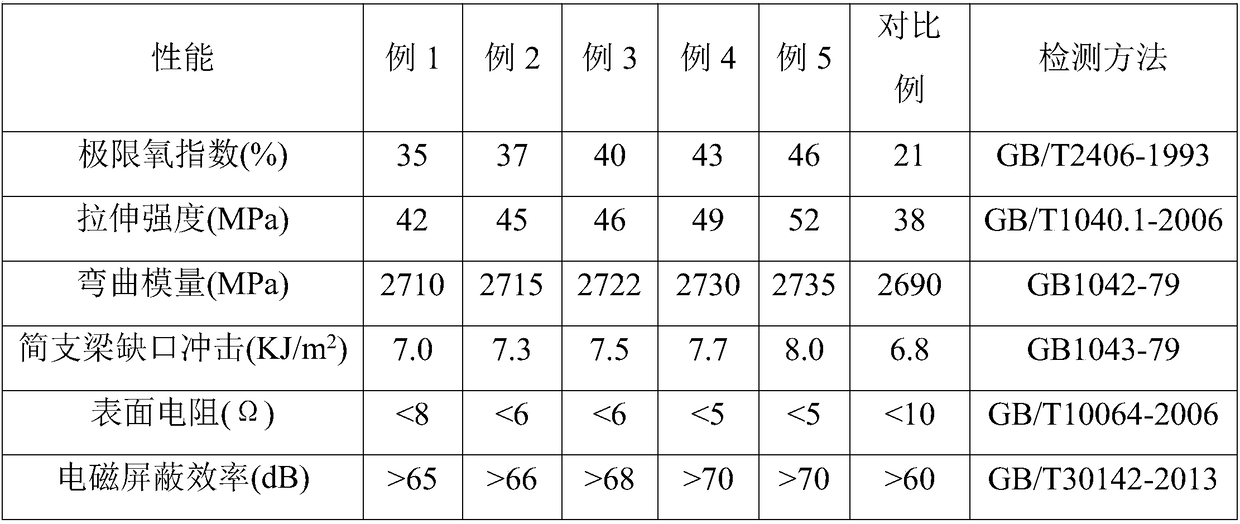

Examples

Embodiment 1

[0026] An electromagnetic shielding plastic, prepared from the following raw materials by weight: 100 parts of polythiophene fluorenone polymer, 10 parts of steel fiber surface modified polypyrrole tube, 10 parts of Sn-Al-O-P, tetraisopropyl 1 part of titanate coupling agent, 1 part of antioxidant 1010.

[0027] The preparation method of the polythiophene fluorenone polymer comprises the following steps: 2,5-di(5-bromothiophen-2-yl)thiophene 20g, 2,5-dihydroxy-9-fluorenone 10g, carbonic acid Add 3 g of potassium to a three-necked flask connected to a water separator, add 100 g of dimethyl sulfoxide and 30 g of toluene, heat the reaction system to 120 ° C, stir and react for 5 hours under nitrogen protection, and remove the generated After removing the water and toluene, the reaction temperature was slowly raised to 135°C, and the reaction was stirred for 8 hours, then 5 g of bis(4-hydroxyphenyl)phenylphosphine oxide was added, and the reaction was continued for 1 hour, and the...

Embodiment 2

[0032] An electromagnetic shielding plastic, prepared from the following raw materials in parts by weight: 100 parts of polythiophene fluorenone polymer, 11 parts of steel fiber surface modified polypyrrole tube, 11 parts of Sn-Al-O-P, silane coupling agent 2 parts of KH550, 10762 parts of antioxidant.

[0033] The preparation method of the polythiophene fluorenone polymer comprises the following steps: 2,5-di(5-bromothiophen-2-yl)thiophene 20g, 2,5-dihydroxy-9-fluorenone 10g, carbonic acid Add 3.5g of cesium into a three-necked flask connected with a water separator, add 115g of N-methylpyrrolidone and 40g of toluene, heat the reaction system to 122°C, stir and react for 5.5 hours under the protection of helium, and remove the reaction mixture through a water separator. The water and toluene generated in the process, after removing all the water, the reaction temperature was slowly raised to 138 ° C, and the reaction was continued for 8.5 hours with stirring, and then 5 g of ...

Embodiment 3

[0038] An electromagnetic shielding plastic, prepared from the following raw materials in parts by weight: 100 parts of polythiophene fluorenone polymer, 13 parts of steel fiber surface modified polypyrrole tube, 13 parts of Sn-Al-O-P, silane coupling agent 2 parts of KH560, 10103 parts of antioxidant.

[0039] The preparation method of the polythiophene fluorenone polymer comprises the following steps: 2,5-di(5-bromothiophen-2-yl)thiophene 20g, 2,5-dihydroxy-9-fluorenone 10g, carbonic acid Add 4g of sodium to a three-neck flask connected to a water separator, add 130g of N,N-dimethylformamide and 45g of toluene, heat the reaction system to 124°C, stir and react for 6 hours under the protection of neon gas, and pass the water separation The water and toluene generated in the reaction process were removed by a device, and the reaction temperature was slowly raised to 141° C. after the water was completely removed, and the stirring reaction was continued for 9 hours, and then 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com