Photoelectric packaging shell and manufacturing process thereof

A technology of manufacturing process and packaging shell, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as surface cracks and air bubbles, achieve high yield, simple manufacturing process steps, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

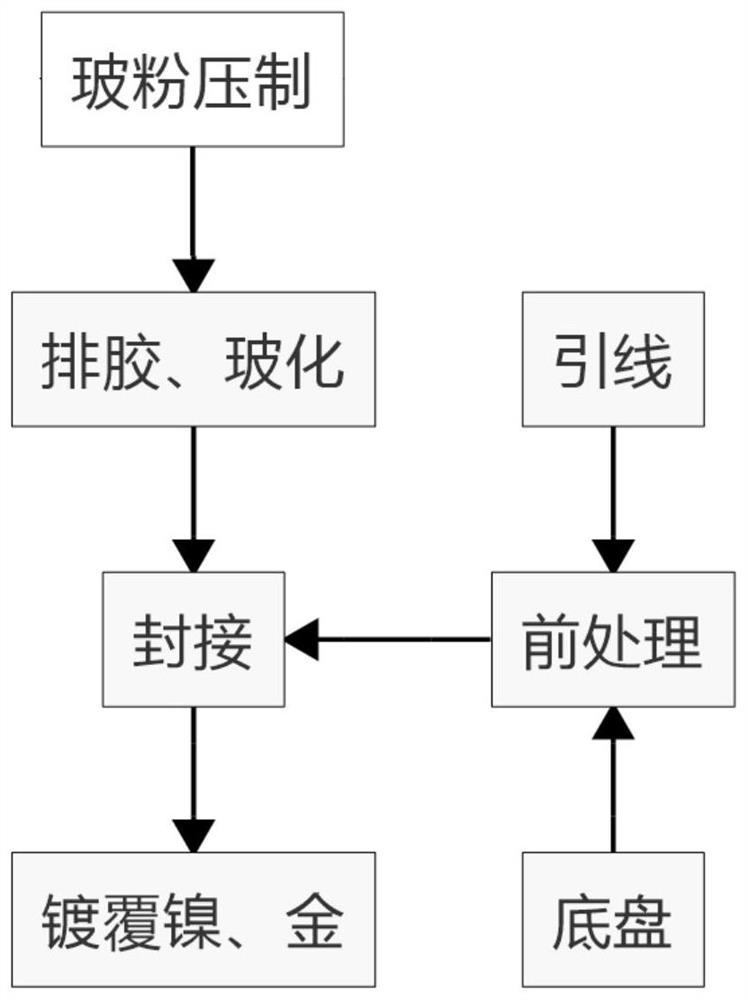

Method used

Image

Examples

Embodiment 1

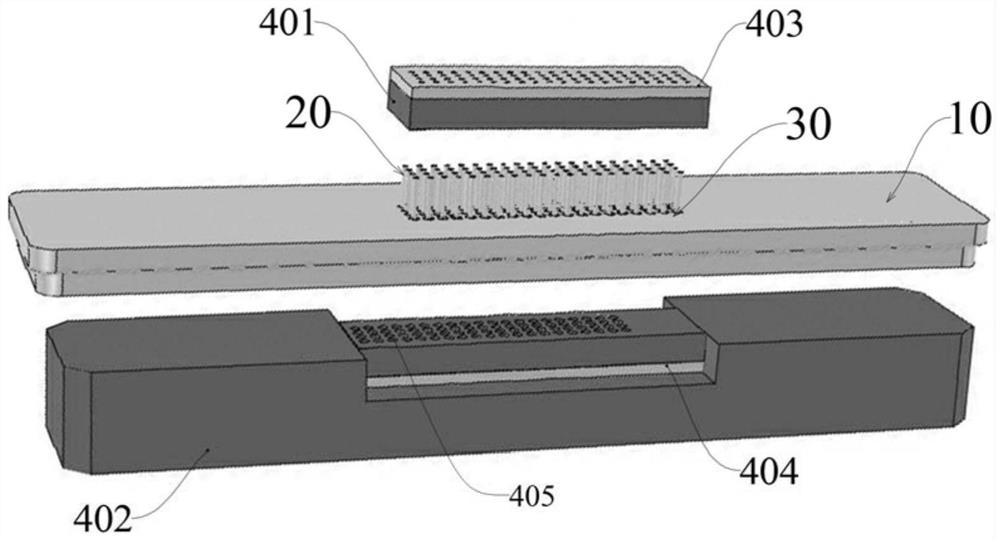

[0048] The pressed glass powder is heated from room temperature to 530°C at a rate of 5°C / min for debonding, then kept at 700°C for 60 minutes, and then cooled to room temperature at a rate of 50°C / min to complete vitrification to obtain a glass insulator;

[0049] The glass insulator, the pre-treated chassis and the leads are fixed by a graphite sealing mold, and then high-temperature sealing is performed.

[0050] The surface of the semi-finished shell is plated with a nickel layer with a thickness of 5.4 μm and a gold layer with a thickness of 2.3 μm to prepare an optoelectronic packaging shell.

Embodiment 2

[0052] This embodiment adopts the same steps as in Embodiment 1, and the specific parameters are shown in Table 1. Other parameters, processes, etc. that are not listed are the same as those in Embodiment 1.

Embodiment 3

[0054] This embodiment adopts the same steps as in Embodiment 1, and the specific parameters are shown in Table 1. Other parameters, processes, etc. that are not listed are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com